Dual-axis drive mechanism and die bonder

一种双轴驱动、结合器的技术,应用在电固体器件、半导体器件、半导体/固态器件制造等方向,能够解决消耗电力增大、Z轴转矩减小、不能实现高速化等问题,达到实现高速化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be described below with reference to the drawings.

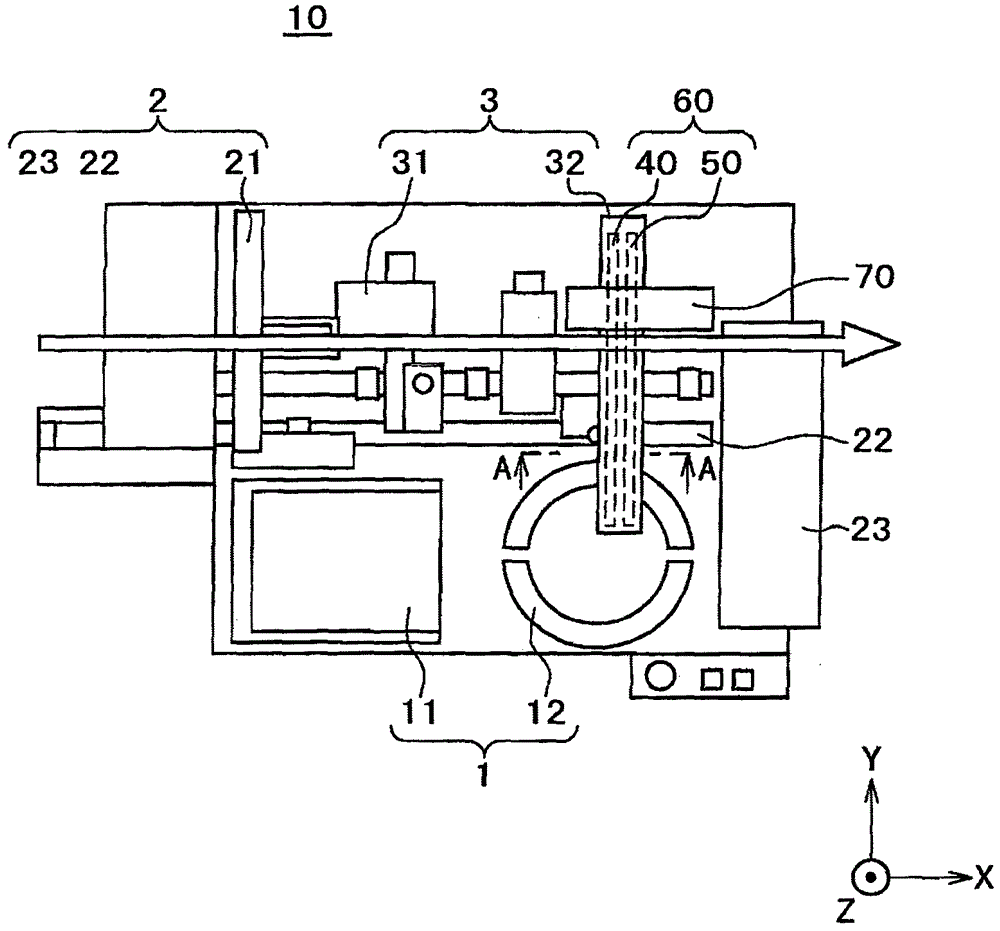

[0030] figure 1 It is a conceptual diagram of the die bonder 10 which is one embodiment of this invention seen from above. The die bonder generally has a wafer supply unit 1 , a workpiece supply and transport unit 2 , and a die bonder unit 3 .

[0031] The wafer supply unit 1 has a cassette elevator 11 and a pickup device 12 . The cassette elevator 11 has a cassette (not shown) filled with wafer rings, and sequentially supplies the wafer rings to the pickup device 12 . The picker 12 moves the wafer ring so that a desired die can be picked up from the wafer ring.

[0032] The workpiece supply and conveyance unit 2 has a stacker 21, a frame feeder 22, and an unloader 23, and conveys workpieces (substrates such as lead frames) in the direction of the arrow. The stacker 21 supplies the workpieces to which the dies are bonded to the frame feeder 22 . The frame feeder 22 conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com