Production process of fermented bean curd and fermented bean curd

A production process and technology of fermented bean curd, applied in the production process of fermented bean curd and the field of fermented bean curd, can solve the problem of single taste of fermented bean curd

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

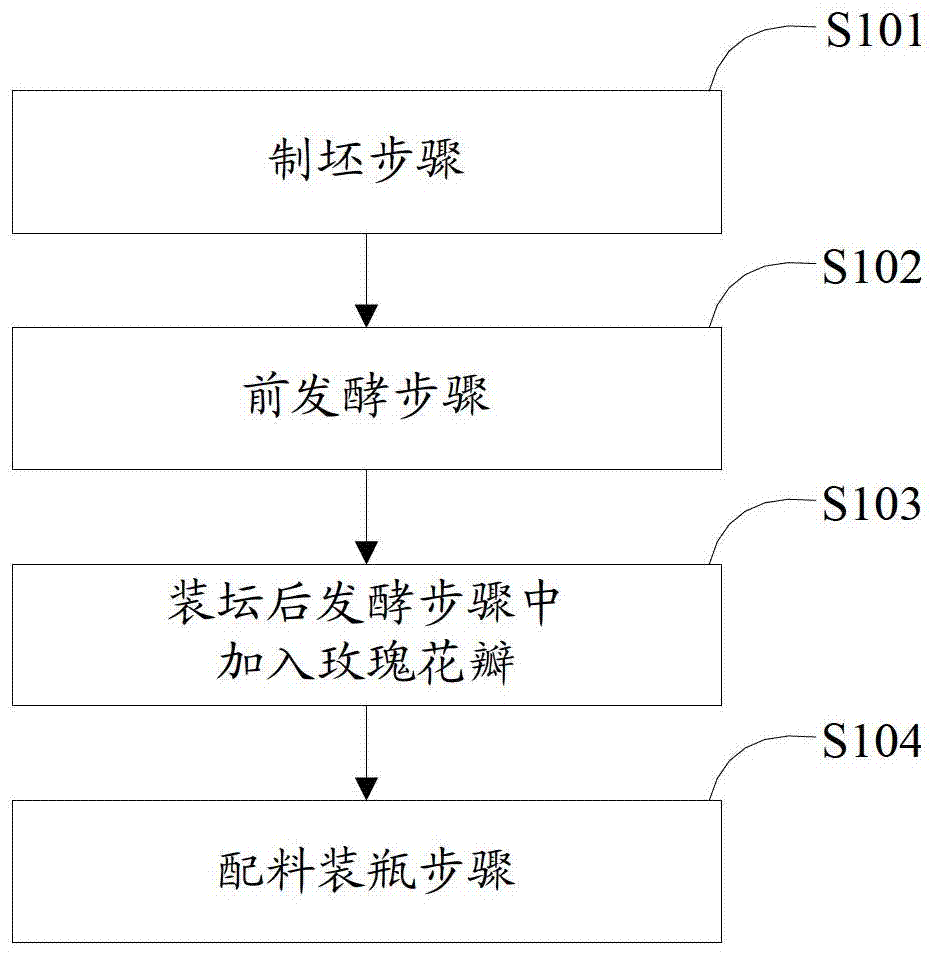

[0018] Embodiment 1, in this embodiment, take adding rose petals as an example in the fermentation step after filling the altar, see figure 1 shown, including the following steps:

[0019] S101, the billet making step.

[0020] 1. Wash and soak soybeans.

[0021] 1) Clean the selected soybeans from impurities, and then soak them in water.

[0022] 2) The time for soaking beans depends on the specific conditions of the temperature. Generally, when the temperature is lower than 15°C in winter, it is about 8-10 hours, and when the temperature is 15-25°C in spring, it is about 6-8 hours; in summer, the temperature is higher than 30 It only takes about 4-6 hours at ℃. The sensory inspection standard for the degree of soaking beans is to break apart the beans, and the inner sides of the two cotyledons are flat, but there is no foam on the surface of the soaking water.

[0023] 3) Inspection: Before and during the cleaning of soybeans, timely remove insect particles, deteriorated...

Embodiment 2

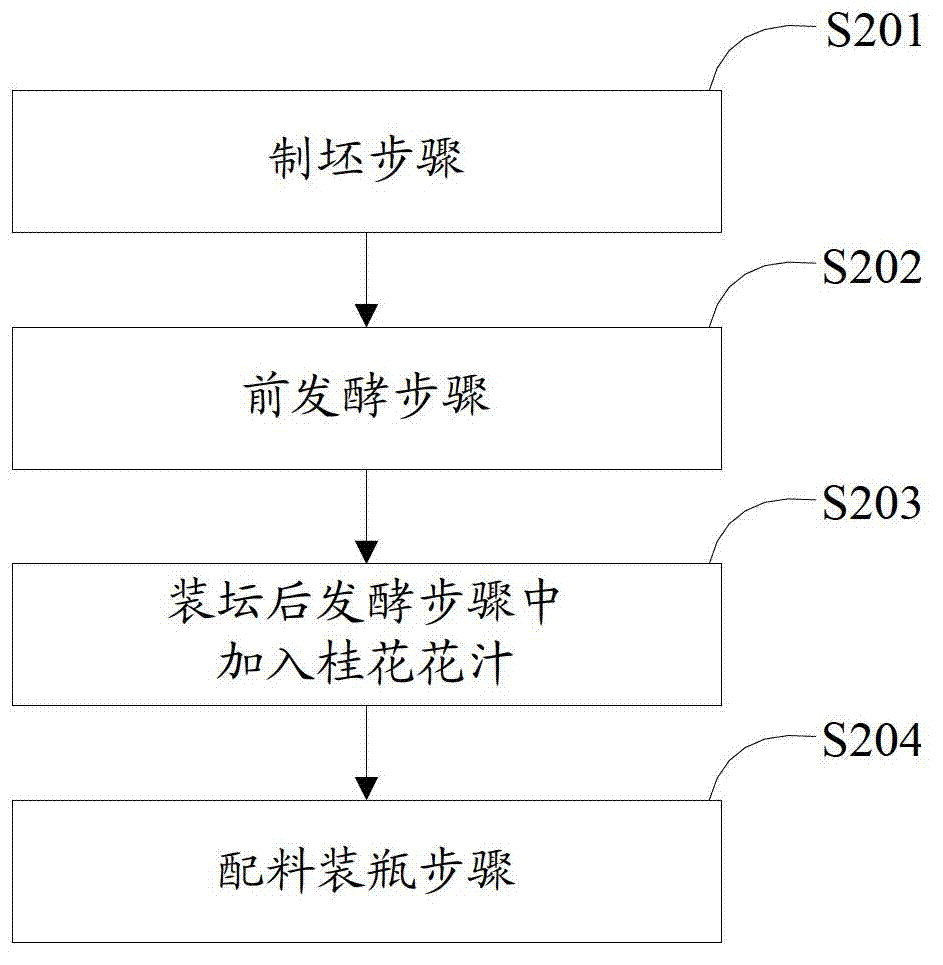

[0071] Embodiment two, in the present embodiment, take adding sweet-scented osmanthus flower juice as an example in the fermentation step after filling the altar, see figure 2 shown, including the following steps:

[0072] S201, the billet making step.

[0073] It is consistent with the step S101 of the first embodiment above, and will not be repeated here.

[0074] S202, pre-fermentation step.

[0075] It is consistent with step S102 in the first embodiment above, and will not be repeated here.

[0076] S203, add sweet-scented osmanthus flower juice in the fermentation step after loading into the altar.

[0077] The difference from the step S103 of the above-mentioned embodiment 1 is that the osmanthus flower juice obtained by pressing osmanthus fragrans is used as the aromatic plant extract, and the osmanthus flower juice is added in this step to finally obtain osmanthus-flavored fermented bean curd.

[0078] S204, the step of bottling the ingredients.

[0079] It is c...

Embodiment 3

[0081] Embodiment 3. This embodiment provides a kind of fermented bean curd, including but not limited to the fermented bean curd production process described in the above-mentioned embodiment 1 or 2. Other fermented bean curd obtained by combining or simply converting the above-mentioned embodiment 1 or 2 are The fermented bean curd described in the present embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com