Microporous self-assembly material with stable aqueous phase and based on nitrogen phosphate heterocycle and preparation method for same

A nitrogen-heterocycle, self-assembly technology, applied in the direction of separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of poor application prospects and poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

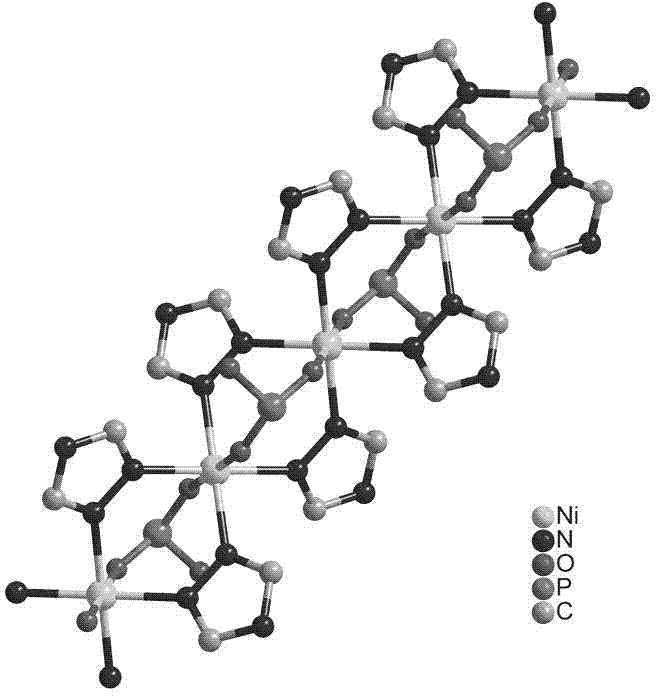

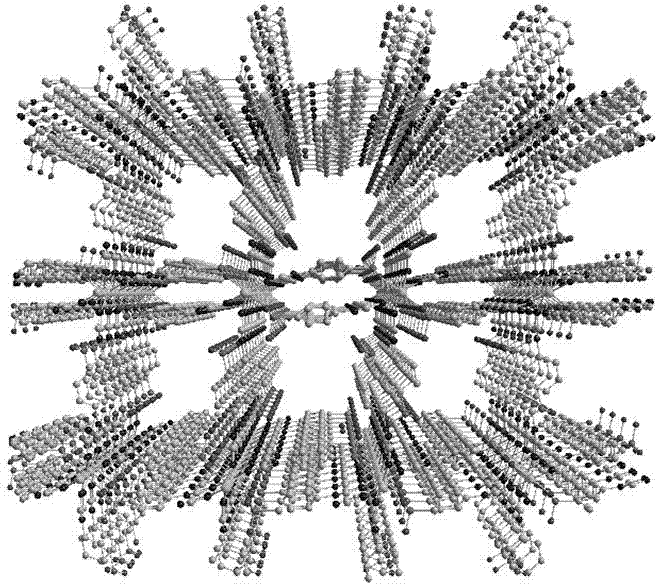

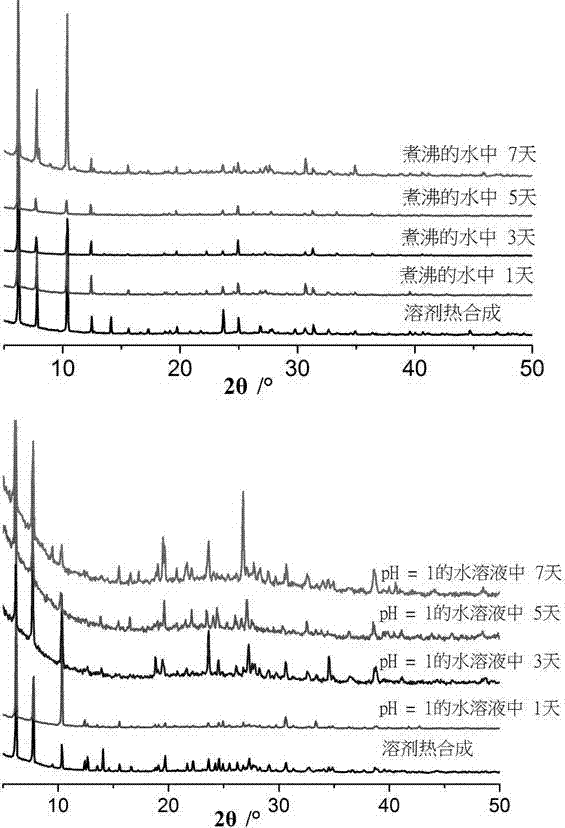

[0022] Add 0.131 g of nickel nitrate, 0.454 g of 4-(3,5-dimethyl-1H-1,2,4-triazole-)phenylphosphoric acid to 8 mL of deionized water and 2 mL of N,N'-di In a mixed solvent of methylformamide, after stirring at room temperature for 30 minutes, a green emulsion was obtained, which was transferred to a stainless steel reaction kettle lined with polytetrafluoroethylene, and reacted at 140 ° C for about 72 hours, and then heated for about 5 Cool at a rate of °C / h, filter to obtain green crystals, wash the crystals three times with deionized water, and dry in an oven at 60 °C for 30 minutes to obtain the microporous self-assembled material.

Embodiment 2

[0024] Add 0.114 g of nickel acetate and 0.204 g of 4-(1,2,4-triazole-)phenylphosphoric acid into 10 mL of deionized water, and stir at room temperature for 60 minutes. Move it to a stainless steel reactor lined with polytetrafluoroethylene, react at 180°C for about 48 hours, then cool at a rate of about 5°C / h, filter to obtain green crystals, wash the crystals three times with deionized water, The microporous self-assembled material was obtained by placing it in an oven at 60° C. for 30 minutes and drying it for 30 minutes.

Embodiment 3

[0026] Add 0.263 g nickel sulfate, 0.280 g 4-(3,5-diethyl-1,2,4-triazole-)phenylphosphoric acid to 7 mL of deionized water and 3 mL of N,N'-dimethyl in a mixed solvent of formamide and stirred at room temperature for 30 minutes. Move it to a stainless steel reactor lined with polytetrafluoroethylene, react at 140°C for about 72 hours, then cool at a rate of about 5°C / h, filter to obtain green crystals, wash the crystals three times with deionized water, The microporous self-assembled material was obtained by placing it in an oven at 60° C. for 30 minutes and drying it for 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com