Keratin fibers conditioning composition

A technology for keratin fibers and conditioning compositions, applied in hair care, cosmetics, cosmetic preparations, etc., can solve problems such as the inability to provide recrystallization of fat phase, achieve excellent conditioning performance, maintain water phase stability, and prevent recrystallization effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0214] The preparation of the keratin fiber conditioning compositions of the present invention may be carried out in any conventional equipment known in the art. Preferably, homogenization is performed in a high shear homogenizer, such as the IKA T25 from IKA and from of

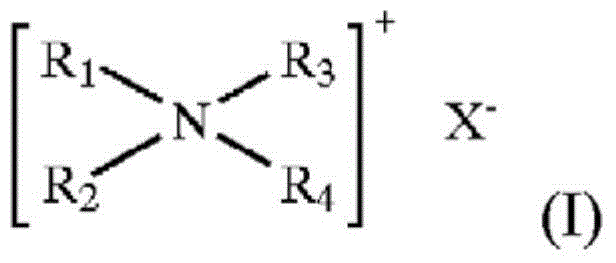

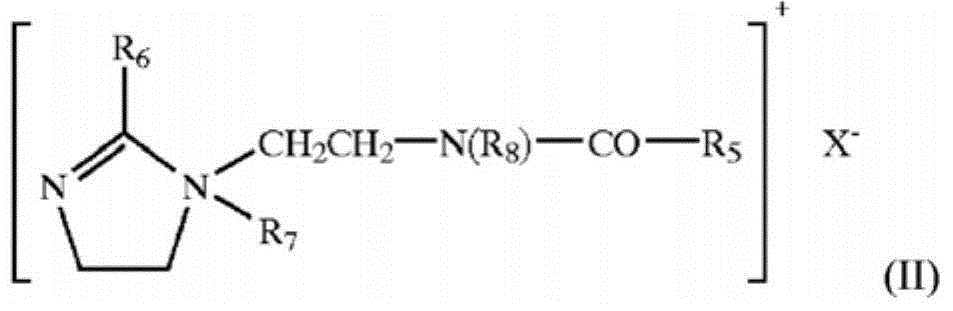

[0215] In another aspect, the present invention also relates to the use of the following combinations of (a), (b), (c) and (d):

[0216] (a) at least one (C 10 -C 30 ) Alkylamino (C 1 -C 8 ) Alkyl (di) (C 1 -C 6 ) alkylamines and their cosmetic salts and their solvates such as hydrates, preferably stearylaminopropyldimethylamine;

[0217] (b) at least one dicarboxylic acid containing at least one hydroxyl group, preferably two hydroxyl groups, said dicarboxylic acid having no cyclic groups;

[0218] (c) at least one high-melting fatty substance having a melting point of 25°C or higher; and

[0219] (d) at least one aqueous carrier,

[0220] wherein (a), (b), (c) and (d) are used together to co...

Embodiment

[0223] The following examples were prepared:

[0224] Table 1

[0225]

[0226] Phase B was prepared by mixing all components and heating to 75°C, then heating Phase A to 80°C.

[0227] Mix phase A and phase B and homogenize for 1 minute with a homogenizer IKA T25 ultra-turrax. The resulting mixture was cooled to a temperature of 30°C with stirring to obtain a hair conditioning composition. All examples were evaluated using wet and dry carding methods.

[0228] Dry combing after washing

[0229] 0.4 g of Comparative Examples 1, 2, 3 and Inventive Example 4 were applied to 6 g of natural black Chinese hair. The conditioning composition is then allowed to rest on the hair for 5 minutes. Hair was then rinsed with hot water for 10 seconds and left overnight at room temperature. The friction between the hair and the polyurethane pad was measured by a Texture Analyzer supplied by Texture Technologies, Scarsdale, USA, before and after treatment with the conditioning composit...

Embodiment 5

[0244]

[0245] Phase A was prepared by mixing all components and heating to 80°C. Phase B was prepared by mixing all components and heating to 75°C. Phases A and B were mixed under stirring and immediately homogenized for 1 minute with a homogenizer IKA T25 ultra-turrax. The resulting homogeneous mixture of Phase A and Phase B was cooled to 30°C with stirring.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com