Manufacturing method of door or window frame angle curved surface structure

A technology of a curved surface structure and a manufacturing method, which is applied in the field of manufacturing a door frame corner or a window frame corner curved structure, can solve the problems of high cost, reduce the manufacturing difficulty and cost of the hyperboloid structure, and the processing difficulty, etc., and achieve low cost and save molds. Cost, wide application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

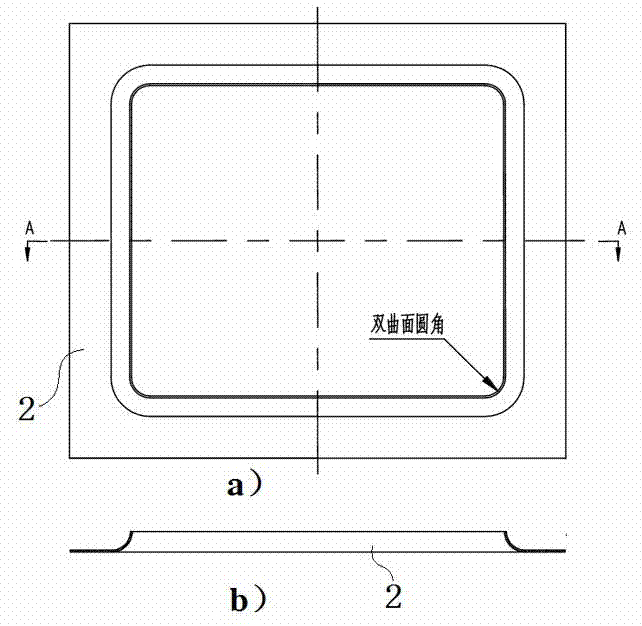

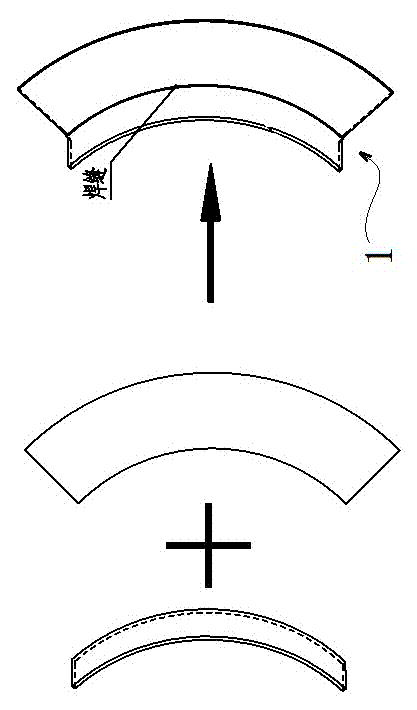

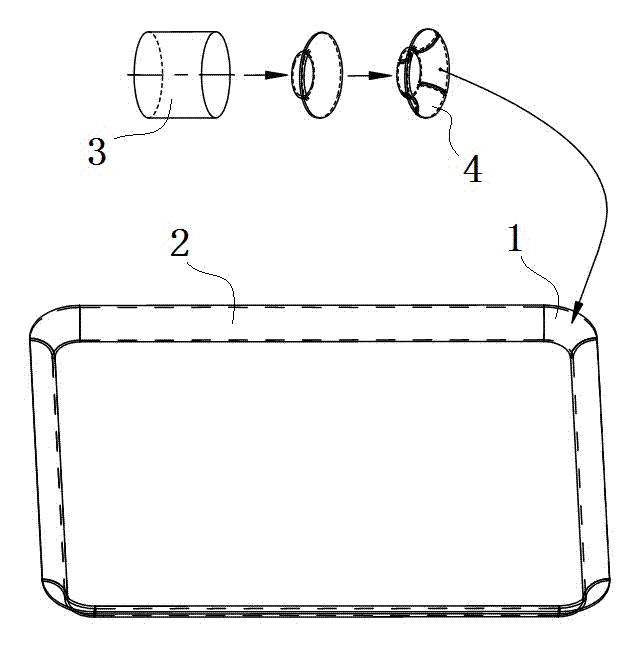

[0022] A method for manufacturing a curved surface structure of a door frame corner or a window frame corner, such as image 3 shown, including the following steps:

[0023] a. Use the central axis of the circular tube or rod-shaped material as the center of rotation to locate, perform machining such as turning, milling or grinding, and process it into a circular horn-shaped hyperboloid component 4;

[0024] b. Then the circular trumpet-shaped hyperboloid part 4 is cut into 4 parts in the radial direction, which is the commonly used door frame corner or window frame corner 2;

[0025] c. Use the four cut door frame corners or window frame corners 2 at the four corners of the door or window 1 to form a door frame or window frame by welding.

[0026] The above-mentioned embodiments should be understood that these embodiments are only used to illustrate the present invention more clearly, and are not intended to limit the scope of the present invention. After reading the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com