Cutter of ring cutting machine

A technology of ring cutting machine and cutting knife, which is applied in metal processing and other directions, can solve the problems of poor cutting quality and low precision, and achieve the effect of good cutting, good continuity and smooth lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

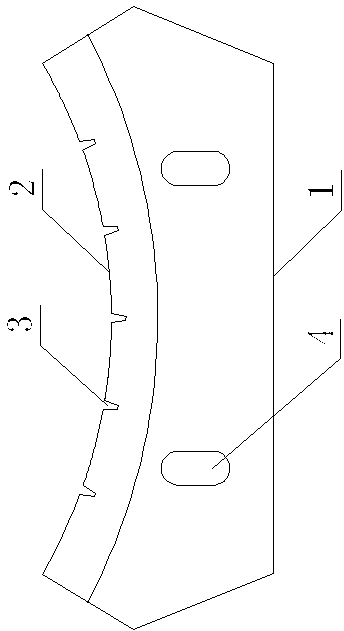

[0012] Such as figure 1 It is a schematic diagram of the structure of the present invention, a cutting knife for a ring cutting machine, including a knife body 1, a knife edge 2, a knife groove 3 and a mounting hole 4, the knife edge 2 is located at the edge of the knife body 1, and the knife groove 3 is located at the knife edge 2, perpendicular to the knife edge 2, The installation hole 4 is arranged on the knife body 1, and the knife groove 3 is trapezoidal. The notch of sipe 3 is wider than the groove bottom. The blade body 1 is circular, and the blade 2 is arc-shaped. The blade 2 and the sipe 3 are distributed on the inner side of the blade body 1 at intervals.

[0013] When in use, fix the knife body 1 on the work surface, and adjust the proper position distance through the oval mounting hole 4 to ensure that the knife edge 2 matches the circular motion track of the bottle cap. When the bottle cap turns to the position of the knife body 1, it contacts the knife edge 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com