Double-sided decoration heat insulation brick-free wall

A thermally insulated, double-sided technology for walls, building elements, coverings/linings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] 1. It is suitable for the wall construction of the existing lower beam ⑥ and column ⑦, and the process flow.

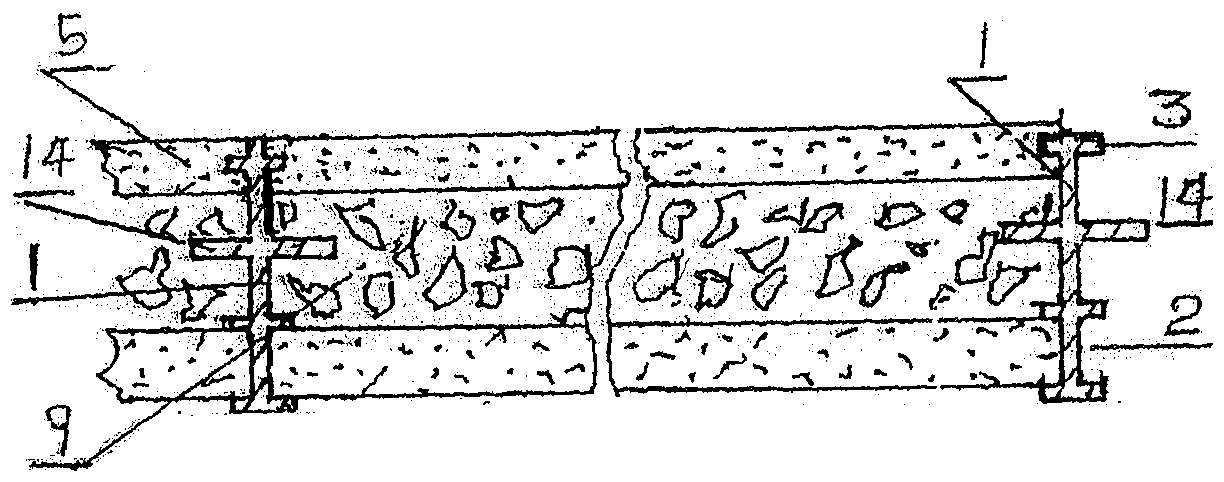

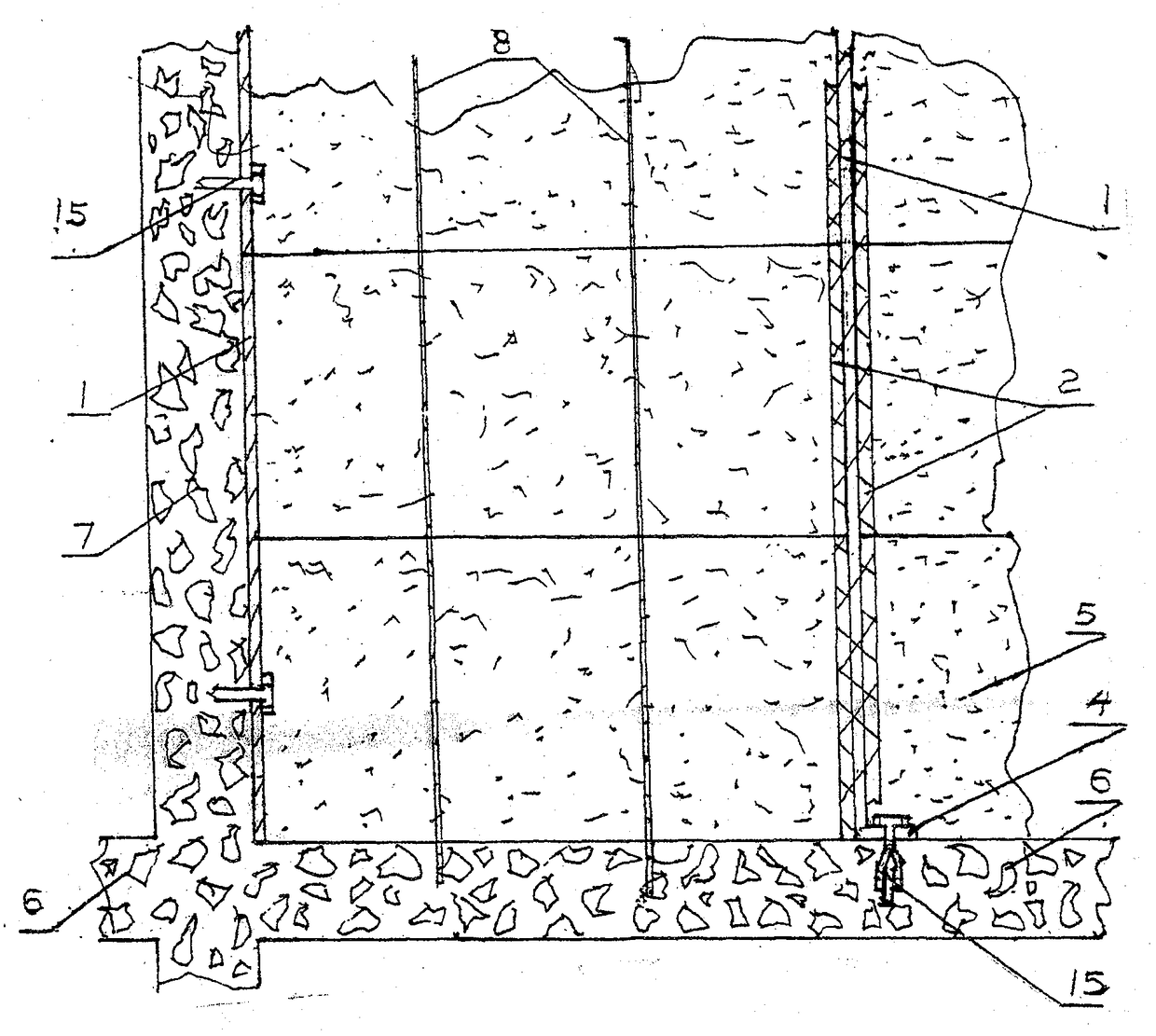

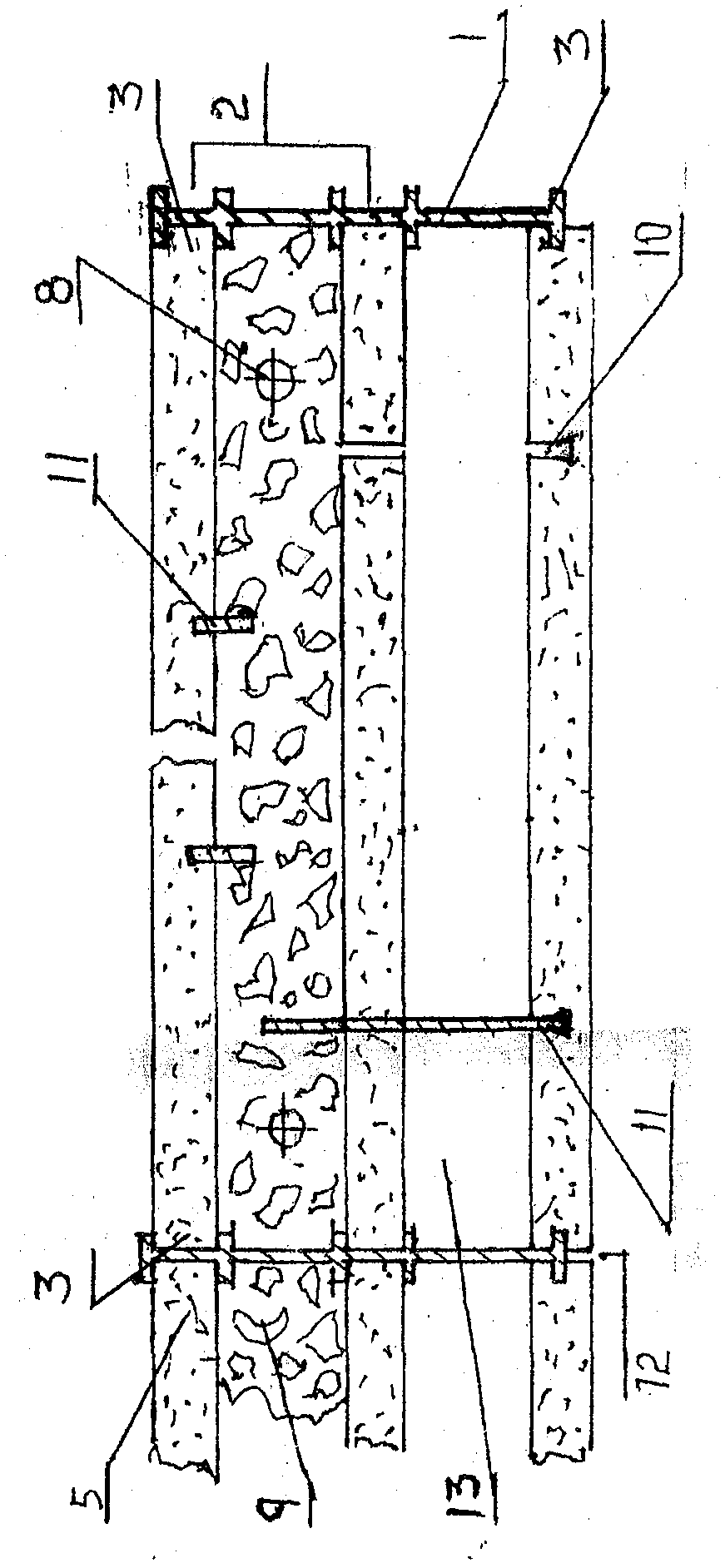

[0015] refer to figure 1 and diagram 2-1 , Figure 2-2 , Figure 2-3 , a double-sided decoration, heat insulation and heat preservation brick-free wall, including the carrier body ① and the steel bar ⑧ that can be installed on the column body ⑦ and the beam body ⑥, and the mounting seat ④ of the carrier body ① has a nail body (15) fixed on the lower beam ⑥ and on the column ⑦, on one side or both sides of the carrier ①, at the middle or the edge of the corner, there are 2 or 4 or 6 installation grooves ② or tenons ③ on the same plane or symmetrically, The groove ② or tenon ③ of the carrier ① has a tenon ③ on the side of the wall brick ⑤ (it can also be used as a tenon ③ along the position) or a strip-shaped installation groove ② on the side to cooperate with each other. The connecting steel bar ⑧ connected to the lower beam ⑥ is placed and connected to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com