Non-residual-tooth plastic steel zipper tooth removing device

A technology of zipper and plastic steel, which is applied in the field of teeth removal devices without residual teeth, can solve problems such as inability to remove residual teeth, residual teeth splashing, etc., to save raw materials, improve the environment, and achieve simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

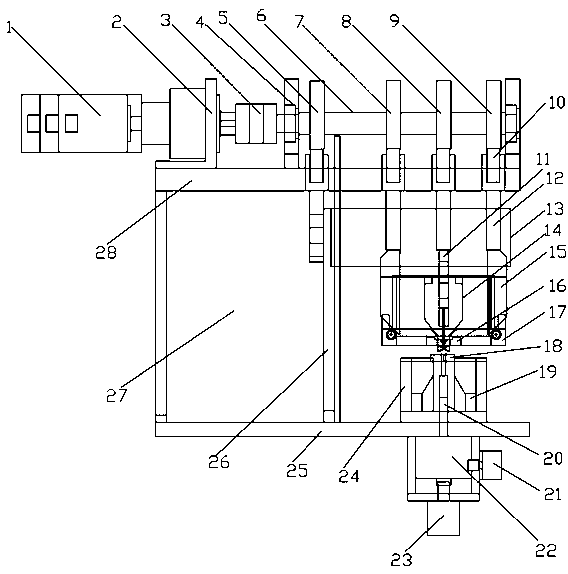

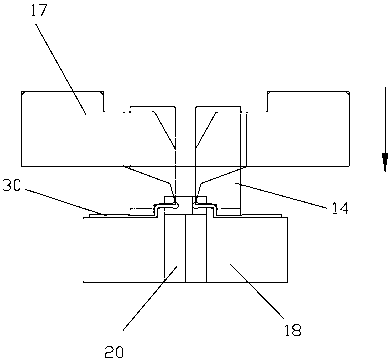

[0022] The present invention will be described in further detail below according to the accompanying drawings

[0023] Such as figure 1 The tooth-removing device for plastic-steel zippers without residual teeth mainly includes a bracket. The bracket is composed of a base plate 25, a main sliding plate 26, a side support plate 27, and a cam seat 28. A motor bracket 2 is arranged above the bracket, and a motor bracket 2 is arranged on the bracket. Servomotor 1, servomotor 1 is connected with rotating shaft 6 through shaft coupling 3 and bearing seat 4, first cam 5, second cam 7, third cam 8, fourth cam 9 are arranged in sequence on rotating shaft 6; Wherein the first cam 5 and the starting position of the rotating shaft 6 are set at 30 degrees, the second cam 7 and the fourth cam 9 are set at 90 degrees with the starting position of the rotating shaft 6, and the third cam 8 is set at 180 degrees with the starting position of the rotating shaft. A cylindrical bearing 10 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com