Technology for modifying vulcanized rubber powder

A technology of vulcanized rubber powder and modification, applied in the direction of plastic recycling and recycling technology, can solve the problems of weak resource concept, neglected application of reclaimed rubber and its rubber powder, etc., and achieve the effect of simple and practical process technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The purpose of the present invention is to provide a process for the modification of vulcanized rubber, which greatly reduces the production cost, and has good compatibility with the new rubber and stable mechanical properties.

[0013] The technical scheme of the present invention is: a process for modifying vulcanized rubber powder, which is characterized in that: with 40-60 mesh rubber powder as the basic amount, the weight ratio of each component is: A, 40-60 mesh vulcanized rubber powder 30 -70 parts B, natural rubber 30-70 parts C, tackifier 1-4 parts D, activator 2-5 parts E, softener 1-4 parts F, vulcanizing agent 2-5 parts

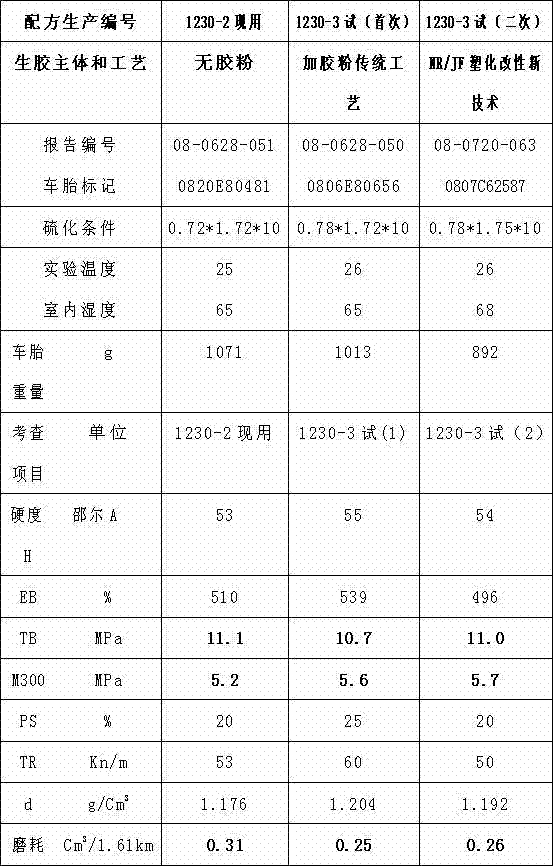

[0014] JF and NR performance comparability analysis model setting;

[0015] As we all know, when a small amount of reclaimed rubber is used in the formula, a certain effective rubber content is generally included according to the performance of the reclaimed rubber. Therefore, the reasonable combination and substitution of vulcanized rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com