Elastic pin coupler

A technology of coupling and elastic column, applied in the direction of elastic coupling, coupling, mechanical equipment, etc., can solve the problem that the wear condition of nylon pin cannot be simple, reliable, intuitive and easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

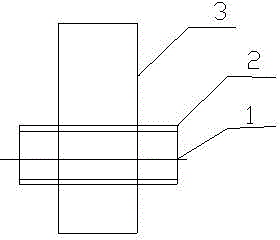

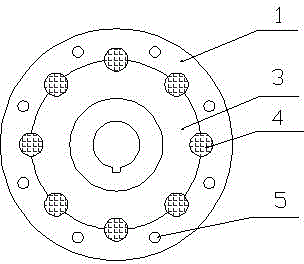

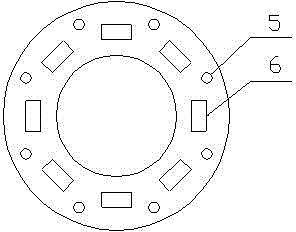

[0023] Such as Figure 1 to Figure 4 As shown, an elastic pin coupling includes an inner ring 3, an outer ring 1, a retaining ring 2 and a nylon pin 4, and the outer ring 1 is provided with a bolt hole 5 for the nylon pin 4 to pass through. The inner ring 3 is connected to the outer ring 1 through meshing teeth, the retaining ring 2 is fixed on the outer ring 1 through threads, and the nylon pin 4 is inserted into the inner ring 3 and the outer ring 1 through the bolt hole 5 , the position corresponding to the nylon pin 4 on the retaining ring 2 is provided with an observation hole 6, the observation hole 6 interferes with the corresponding nylon pin 4, and the visible range formed by the observation hole 6 covers the edge of the nylon pin 4 .

[0024] special observation Figure 4 , it can be seen that there are eight rectangular observation holes drilled along the inner circle of the retaining ring 2, and the positions of the eight rectangular observation holes 6 are exact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com