Control system of electric execution mechanism

An electric actuator and control system technology, applied in engine components, mechanical equipment, valve operation/release devices, etc., can solve problems such as valve stem pull-off, reverse, valve position stroke change, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

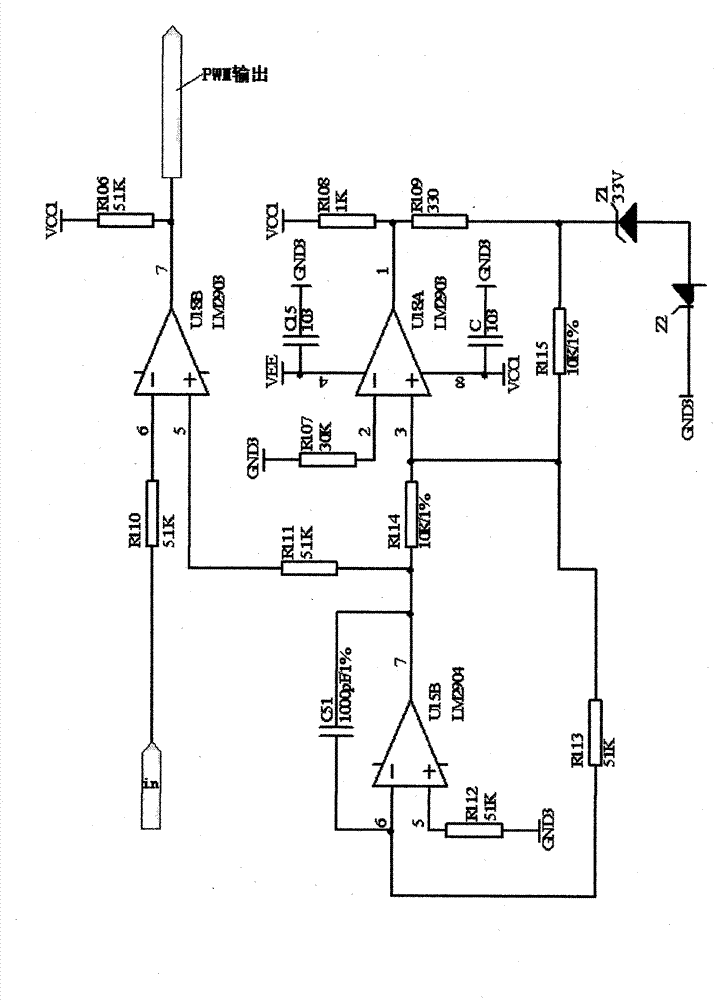

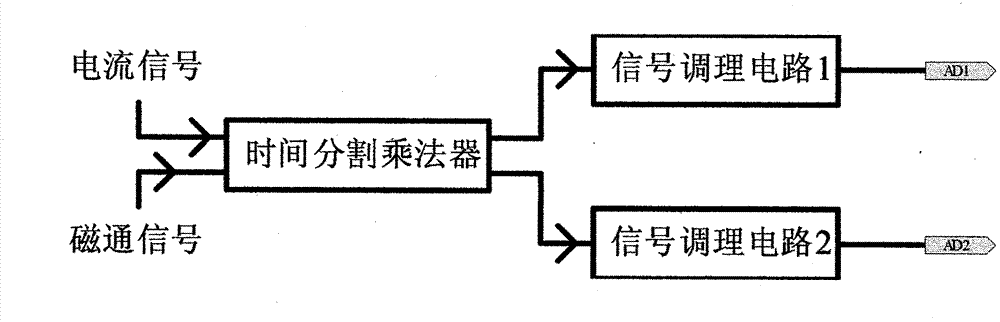

[0041] 1. Use dual-channel electronic circuit to realize torque measurement:

[0042] According to T=K*I 2 *Φ 1 *cosθ 2 For torque protection:

[0043] 1. Multiplication principle:

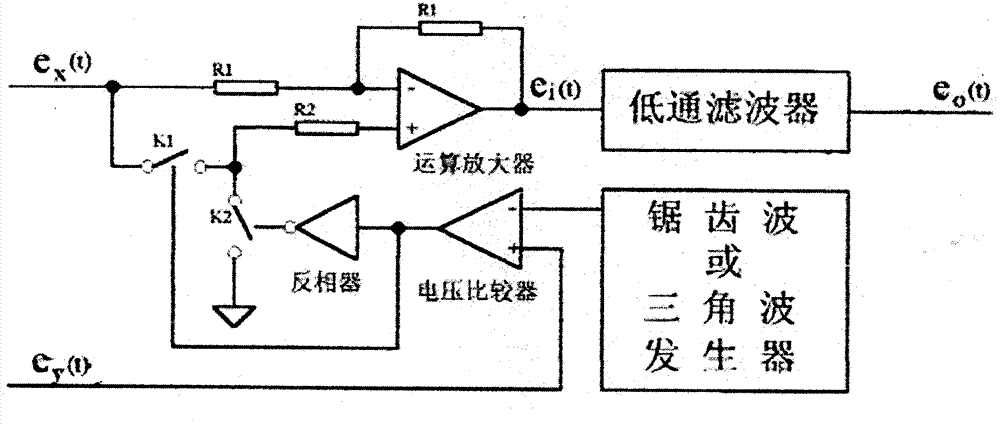

[0044] Using pulse width modulation (PWM) to realize multiplication is also called time division multiplication, which combines pulse width and amplitude modulation to realize the multiplication of two analog signals.

[0045] figure 1 It is the functional block diagram of the multiplication operation. The period T of the pulse signal output by the pulse width modulator is fixed, but the pulse width T 1 By analog signal e y modulation. by e y The modulated PWM wave controls the action of the switch K.

[0046] at T 1 During the period switch K turns on the analog signal e x , during T2=T-T1, the switch K is turned on-e x . So there are:

[0047]

[0048] According to formula (1), e can be i Think of it as a superposition of two sampling processes. Suppose two rectangular pulse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com