Integrally-molded welding-line-free heating radiator and manufacturing method thereof

An integral molding and production method technology, applied in the field of radiators, can solve the problems of easy scale generation, high power consumption, and low heat utilization, and achieve the effects of avoiding secondary heat exchange, strong pressure bearing capacity, and high heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

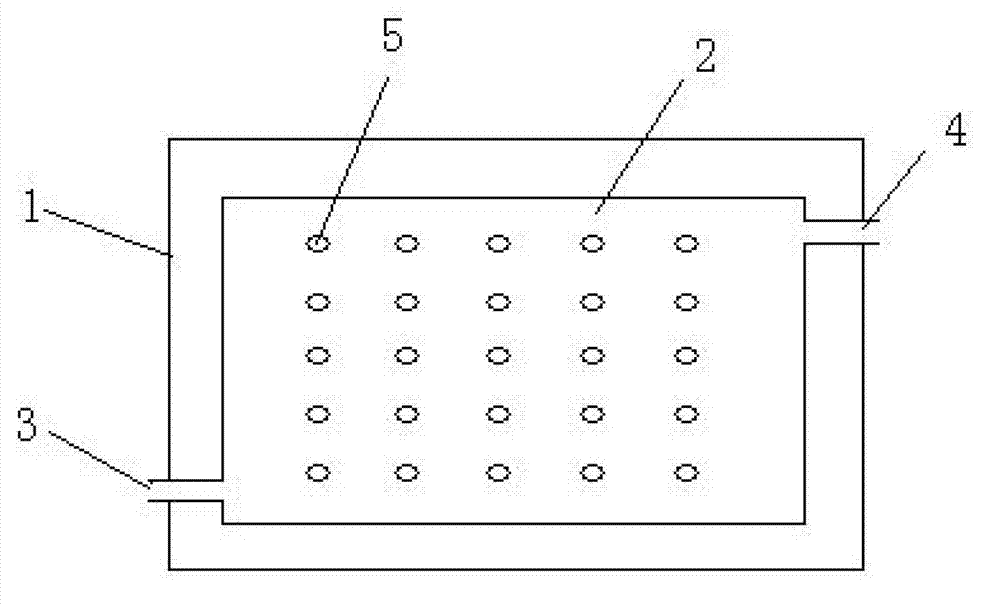

[0022] This embodiment describes an integrally formed weldless radiator and its production method, which includes an integrally blown shell 1, the shell 1 is made of aluminum and has an inlet 3 and an outlet 4 inside. medium channel. Such as figure 1 As shown, a large cavity 2 is formed in the middle of the medium channel, and support columns 5 are arranged in the large cavity 2, and the structure has sufficient heat dissipation.

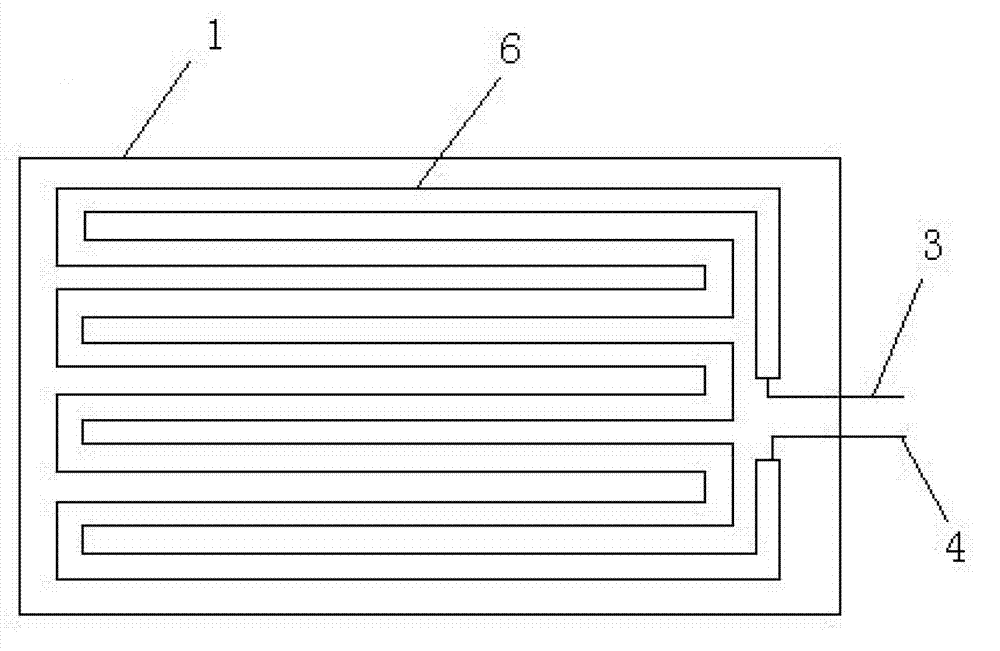

[0023] The medium channel can also communicate with a plurality of branch channels 6 at the entrance, and the branch channels 6 are arranged in a bow shape and each branch channel 6 converges at the outlet of the medium channel, such as figure 2 As shown, the effect of uniform heat dissipation is achieved; the medium channel can also be shunted in the first half, and a large cavity is formed in the second half. Support columns are arranged in the large cavity, and the arrangement forms are various, all within the scope of protection of this techni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com