Direct-expansion type solar heat and electricity co-generation system provided with two stages of heat storage water tanks

A combined heat and power supply and hot water tank technology, which is applied in solar thermal power generation, mechanical power generated by solar energy, energy industry, etc., can solve the problems of high technical difficulty, poor independence of power generation and heat supply, and high cost, and avoid two Second heat exchange, easy access, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

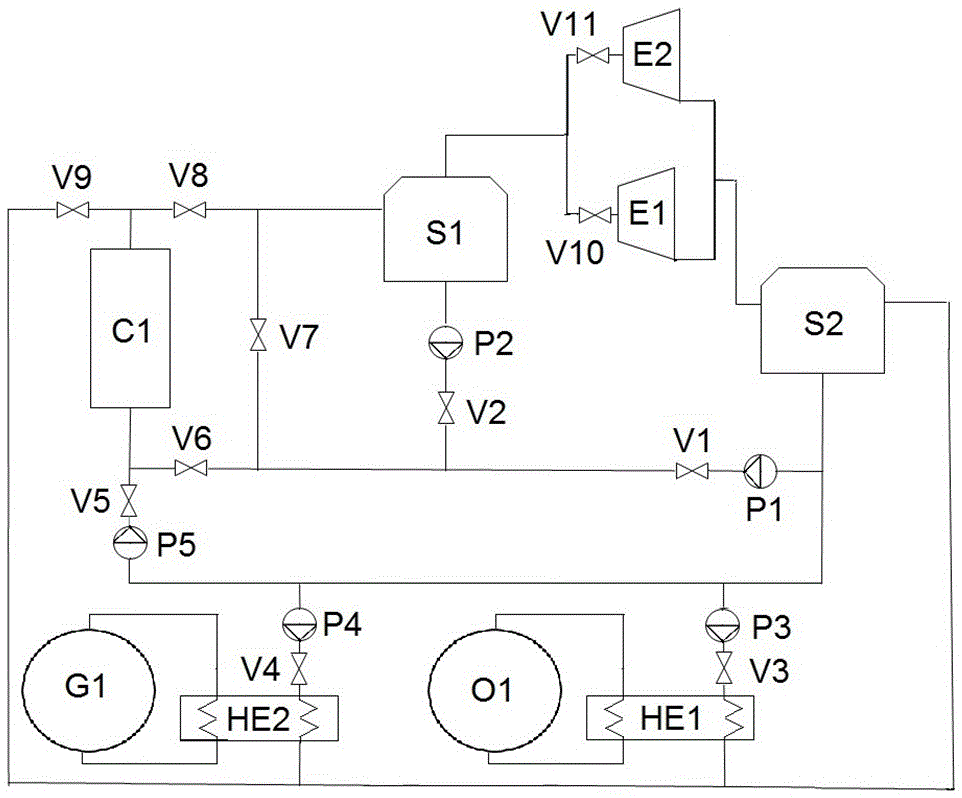

[0077] Embodiment 1 works in mode 1: the system needs to generate power at full power, but does not need external heat supply.

[0078] see figure 2 , the first outlet of the high-temperature water storage tank S1 is connected to the inlet of a screw expander E1 through a valve (only a single steam screw expander works).

[0079] In this mode 1, the first valve V1, the third valve V3, the sixth valve V6, the eighth valve V8 and the tenth valve V10 are opened, and the other valves are closed. The first water pump P1 and the third water pump P3 operate, and the other water pumps are turned off. Both a steam Rankine cycle at the top and an organic Rankine cycle at the bottom connected to the first heat exchanger HE1 are in operation. The water is heated and evaporated in the heat collector array C1, and enters the steam screw expansion unit E1 after passing through the high-temperature heat storage tank S1, and outputs work during the enthalpy drop process. The water vapor at...

Embodiment 2

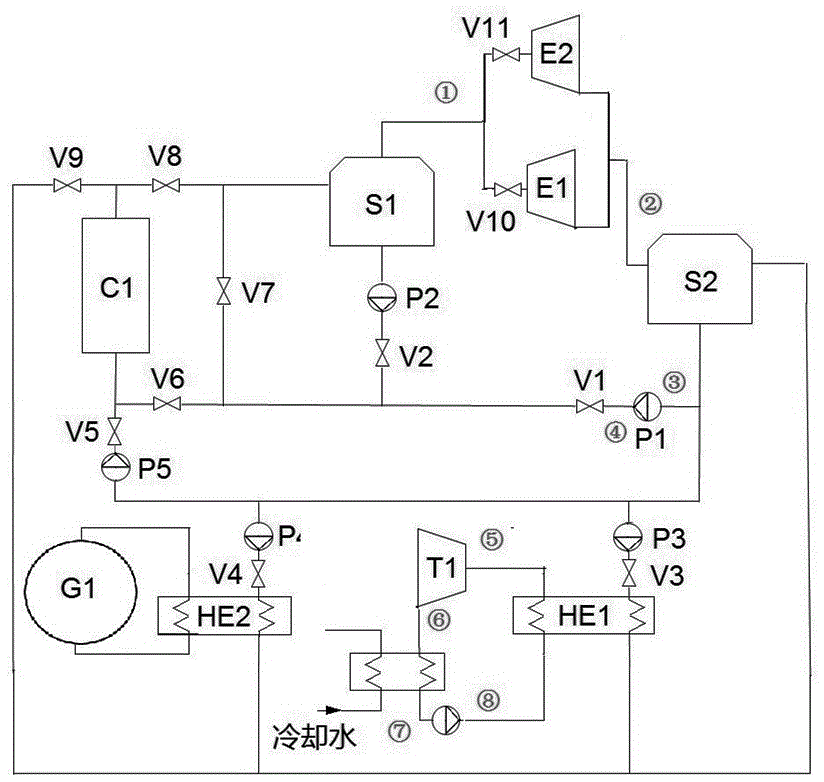

[0101] Embodiment 2 works in mode 2, that is, the system needs to generate power at full power, and at the same time needs to supply external heat. see figure 2, Compared with Example 1, Example 2 adds a screw expander E2, and the generating power is the same as that of the screw expander E1, which is 596kW. Collector array area from 8333m 2 increased to 13020 m 2 . The power of the ORC expander remains unchanged. The heating power of the heating system G1 is 2000kW.

[0102] In this mode 2, the first valve V1 , the third valve V3 , the fourth valve V4 , the sixth valve V6 , the eighth valve V8 , the tenth valve V10 and the eleventh valve V11 are opened, and the other valves are closed. The first water pump P1, the third water pump P3 and the fourth water pump P4 operate, and the other water pumps are turned off. While generating electricity at full power, the system provides heat to users through the fourth water pump and the second heat exchanger HE2.

[0103] Using ...

Embodiment 3

[0107] Embodiment 3 works under mode 7, that is, the system does not need to generate electricity, and does not need to supply heat.

[0108] In mode 7, the fifth valve V5 and the ninth valve V9 are opened, and the other valves are closed. The fifth water pump P5 runs, and the other water pumps are turned off. The heat obtained by the collector array C1 is stored in the low temperature storage tank S2.

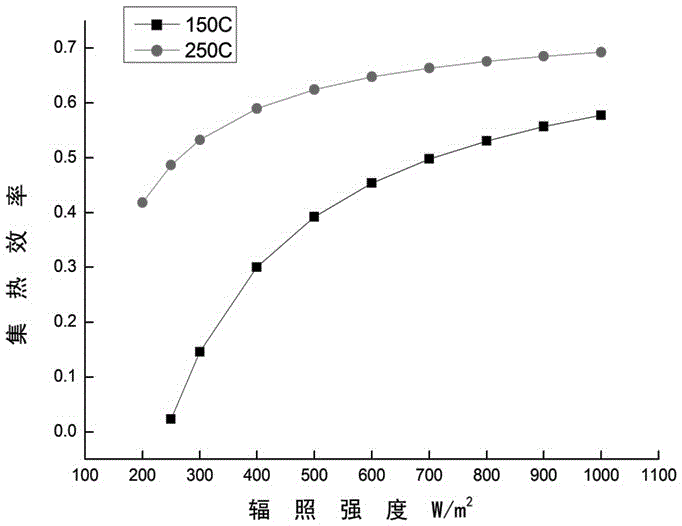

[0109] Take a type installed in the United States with a collector area of 2700 m 2 Taking the trough parabolic collector as an example, the optical efficiency of the collector is 0.762, and the first heat loss coefficient is 0.2521W / (m 2 K), the second heat loss coefficient is 0.002672W / (m 2 K 2 ). When the working temperature is 250°C (corresponding to high-temperature storage tank S1) and 150°C (low-temperature storage tank S2), the change of collector efficiency with radiation intensity is as follows: image 3 shown.

[0110] image 3 It shows that the heat colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com