Magnetic rack combination

A magnetic frame and side plate technology, applied in the direction of digital processing power distribution, etc., can solve the problems of impacting the magnetic frame, inconvenient assembly, loud noise, etc., and achieve the effect of reducing noise, convenient assembly, and avoiding direct contact and collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

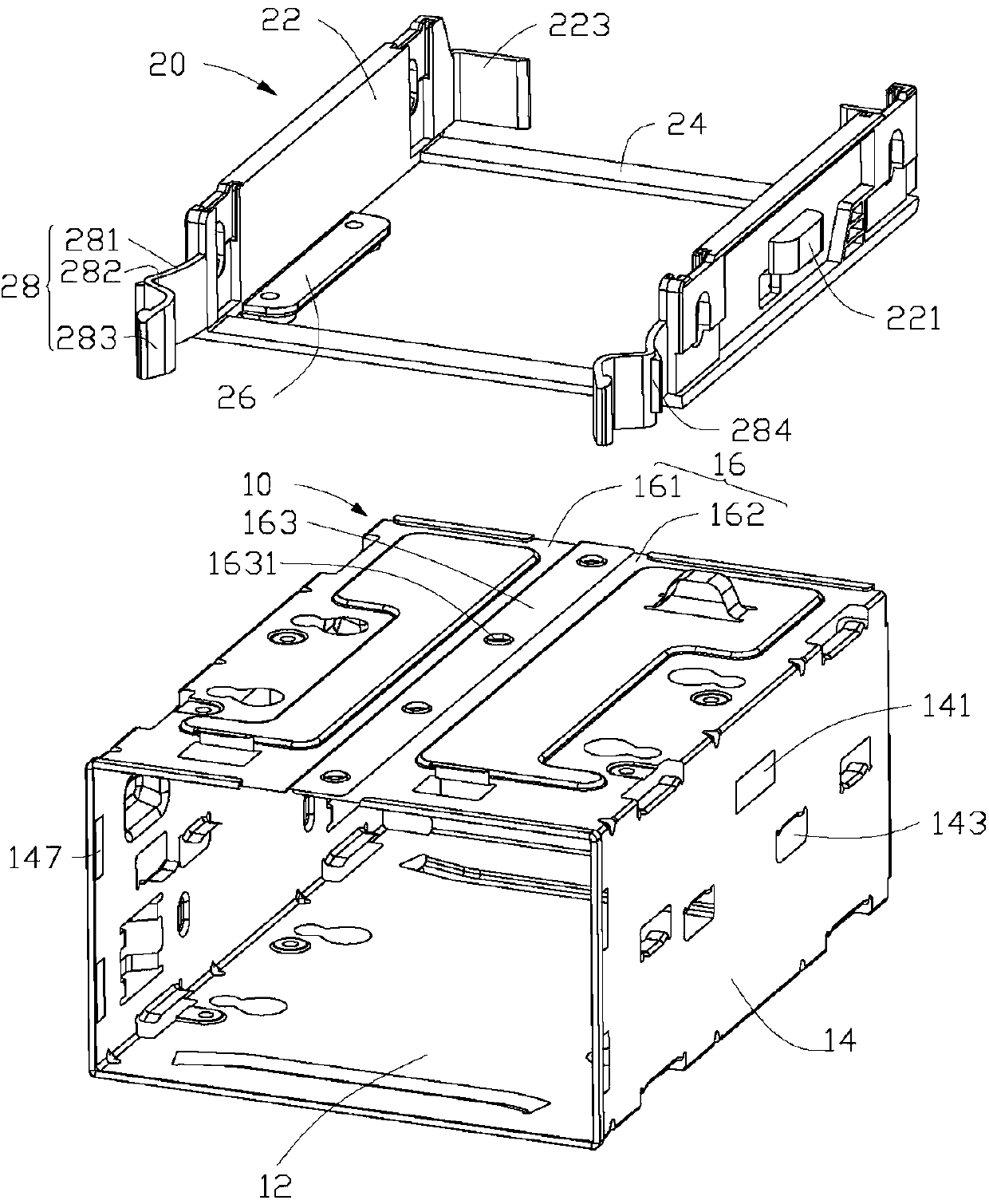

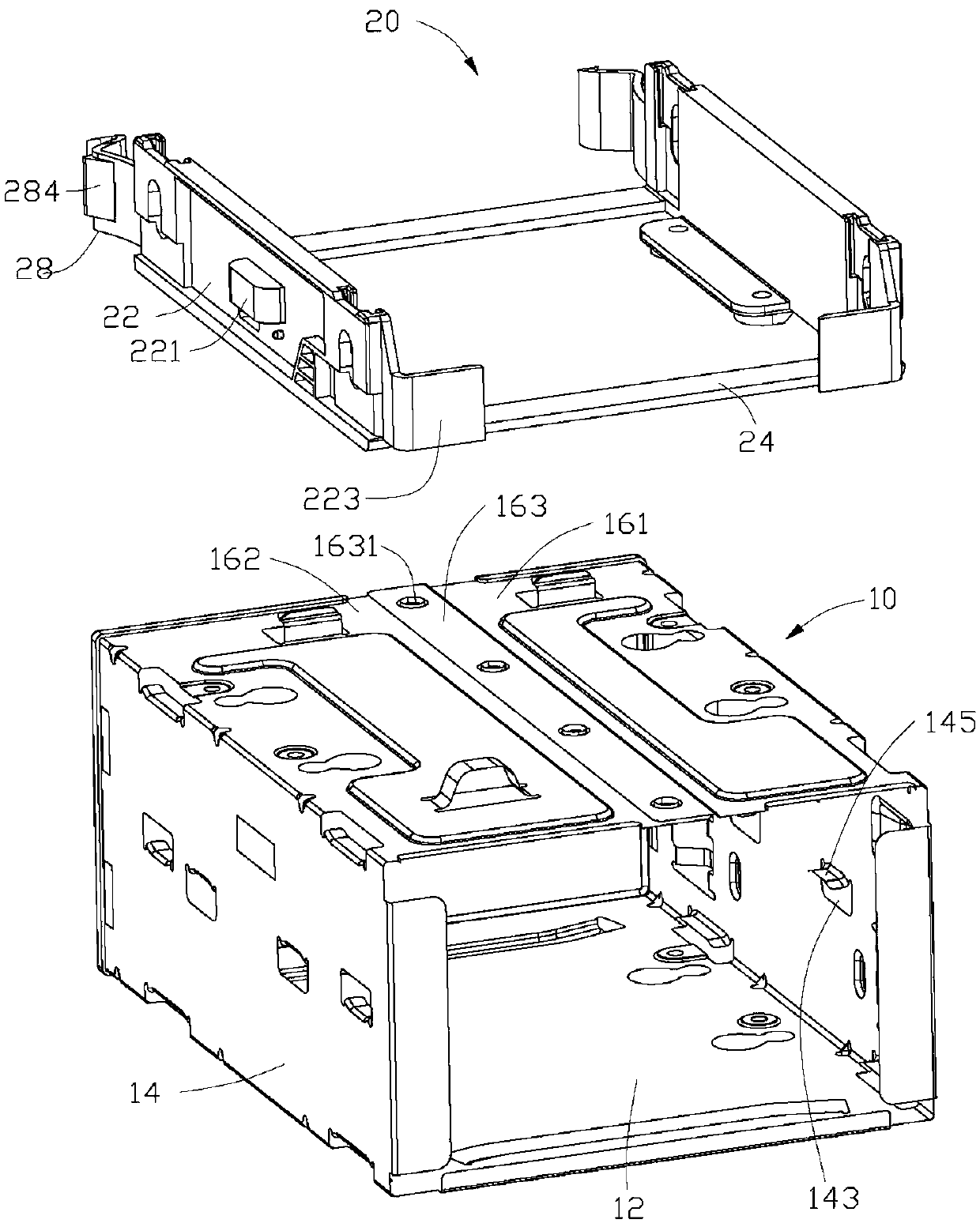

[0013] see Figure 1 to Figure 3 , The preferred embodiment of the present invention, the magnetic shelf assembly includes a magnetic shelf 10 and a tray 20 .

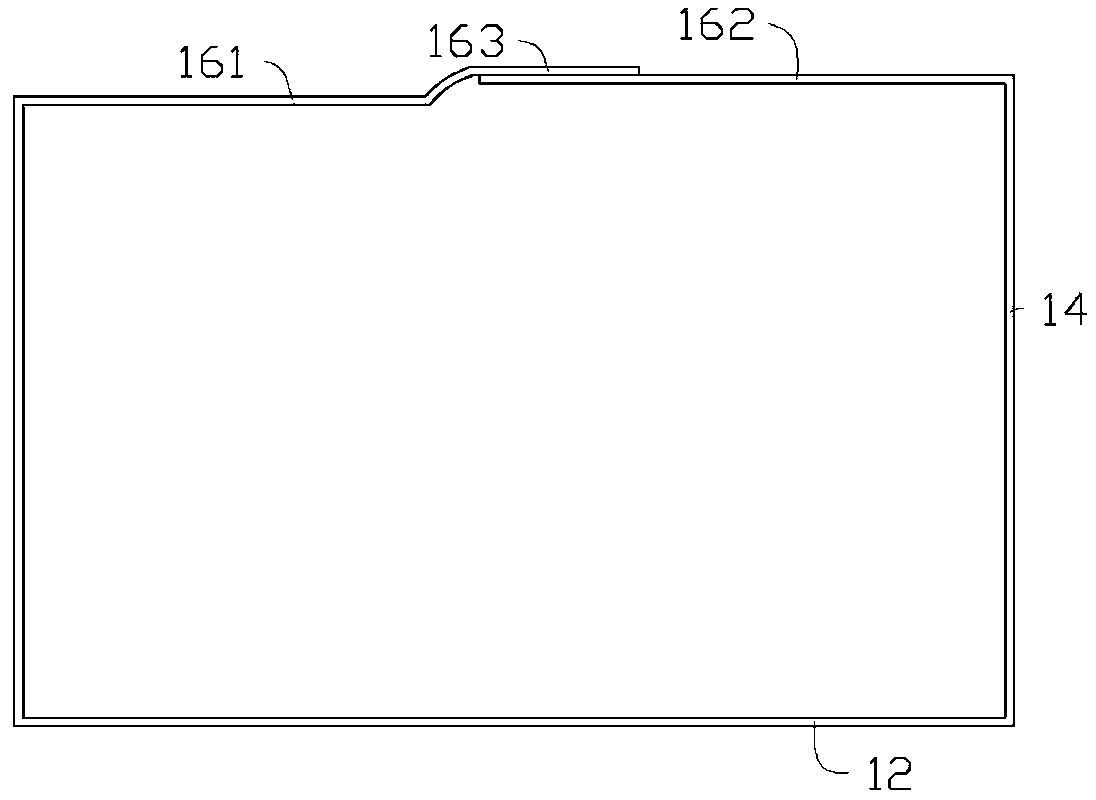

[0014] The magnetic frame 10 includes a bottom plate 12 , a pair of side plates 14 vertically extending upward from left and right side edges of the bottom plate 12 , and a top plate 16 connected between top edges of the pair of side plates 14 . The top board 16 includes a first board body 161 and a second board body 162 vertically extending from top edges of the pair of side boards 14 . The first plate 161 includes a folded edge 163 attached to the second plate 162, the folded edge 163 is provided with a number of fixing holes 1631, the second plate 162 is adjacent to the first One end of the board body 161 is also provided with a fixing hole or a fixing column corresponding to the fixing hole 1631 to facilitate fixing the folded edge 163 of the first board body 161 on the second board body 162 . In a preferred embo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap