Cordwood power capacitor

A technology of power capacitors and building blocks, applied to AC networks to reduce harmonics/ripples, reactive power compensation, harmonic reduction devices, etc., can solve the problem of inconvenient user expansion and transformation, human and material resources affecting user use, and affecting products Service life and other issues to achieve the effect of improving equipment utilization, improving voltage quality, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

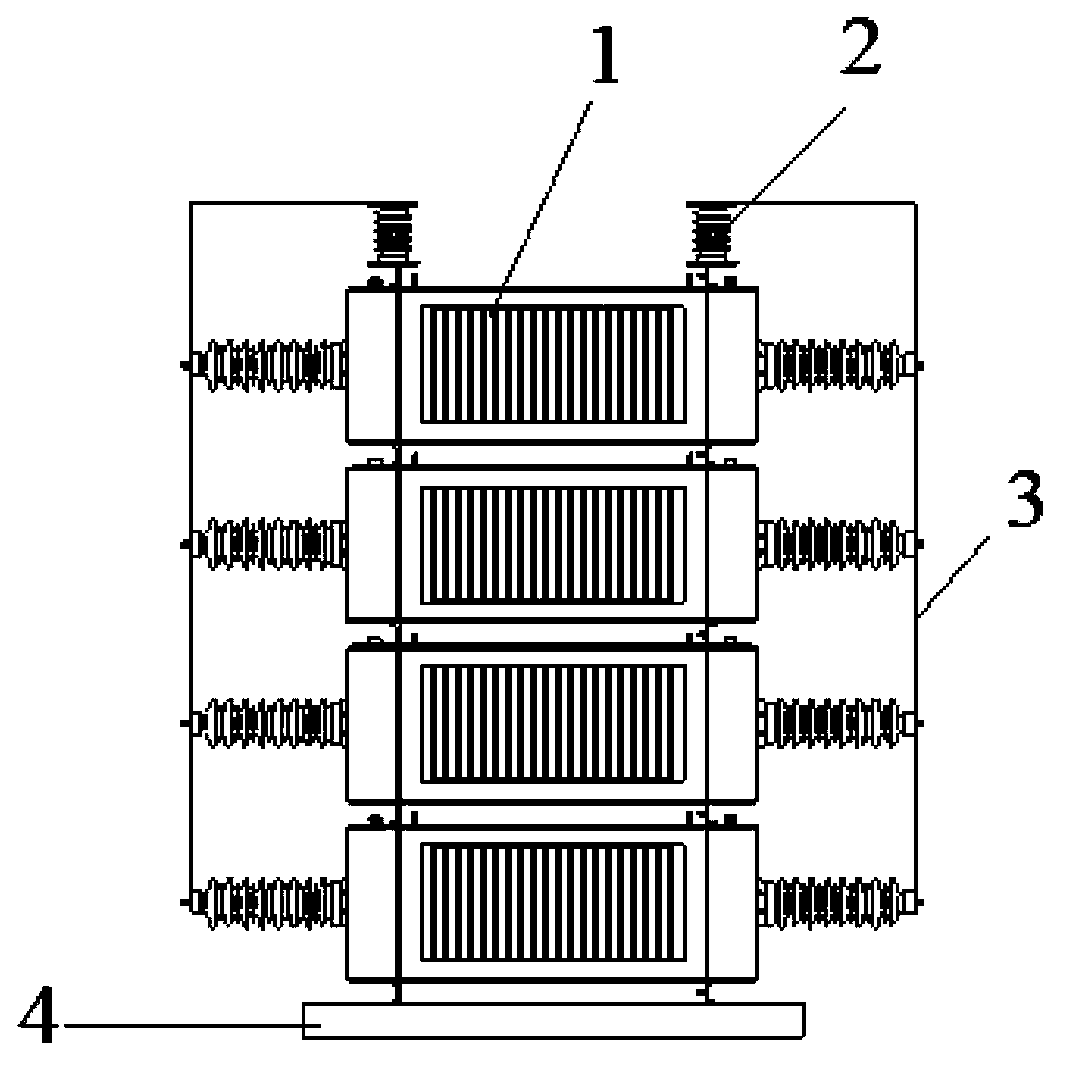

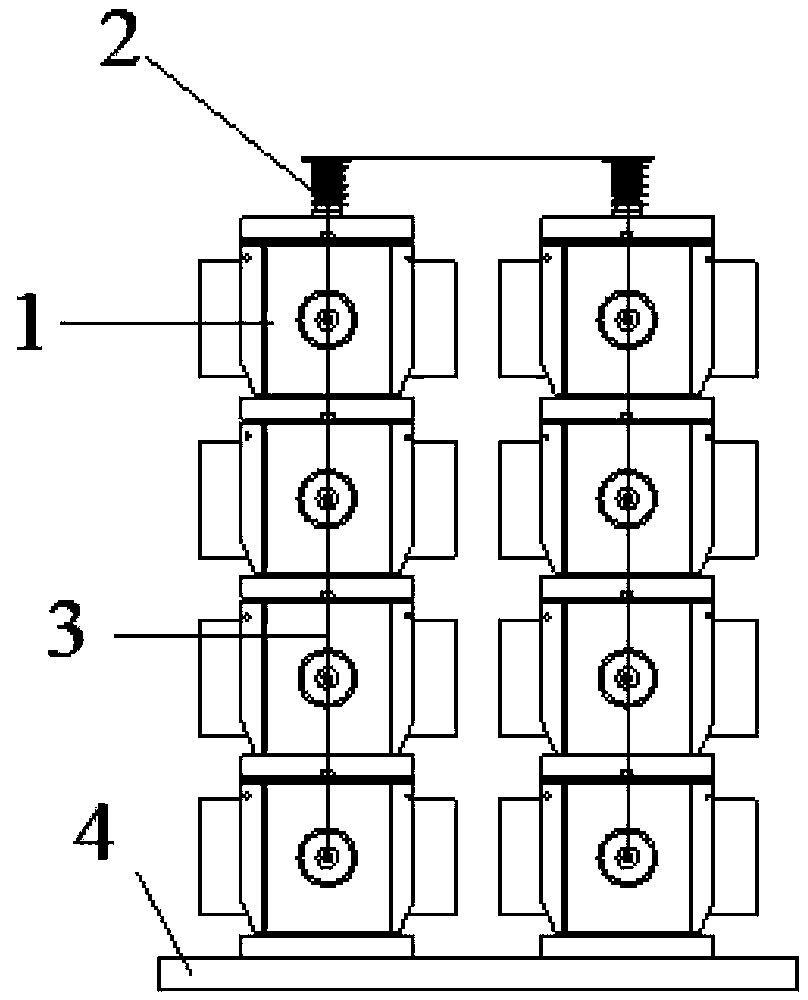

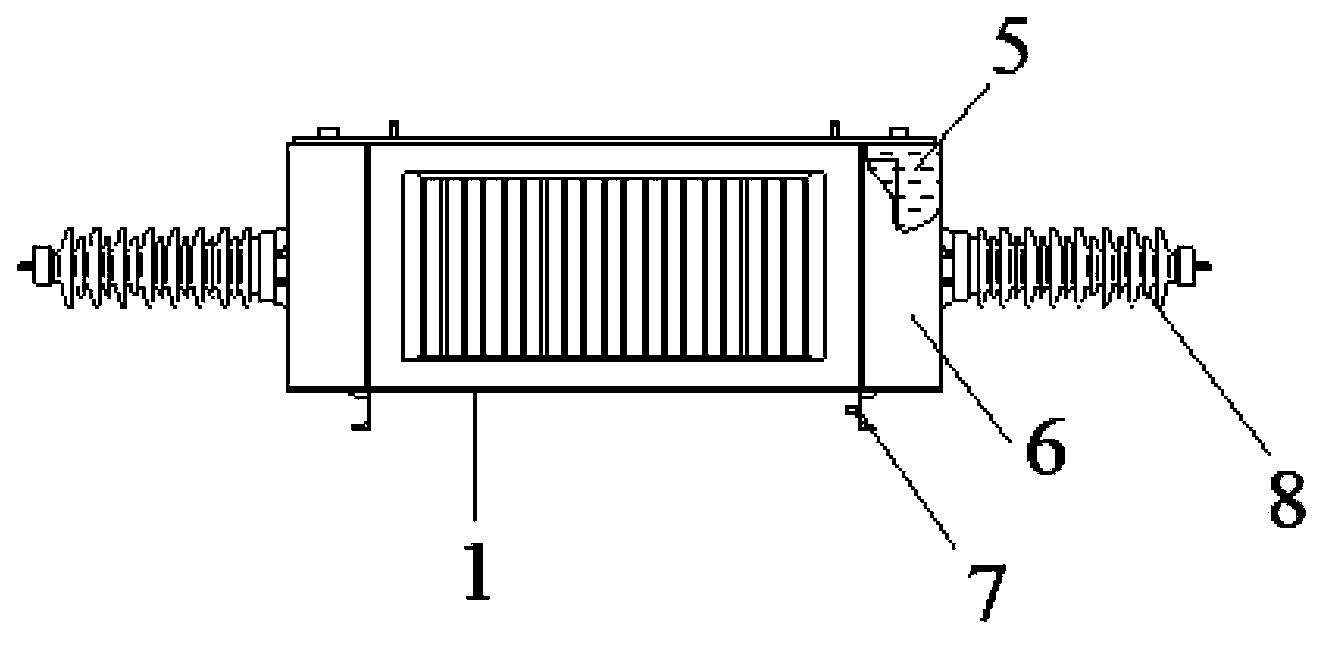

[0015] The structure of the building block power capacitor of the present invention is as follows Figure 1-Figure 4 As shown, it includes 3 or more building block power capacitor modules 1. A plurality of building block power capacitor modules 1 are assembled by bolt connection and assembly to form a capacitor bank, and the building block power capacitor module 1 and the post insulator 2 are connected by bolts , The building block type power capacitor module 1 is provided with a bushing 8, and the electrical connection between the building block type power capacitor modules 1 and between the capacitor banks is realized through the bus bar 3. The entire capacitor bank is located on the foundation base 4, which can realize rapid installation on site, and facilitate on-site expansion according to the capacity requirements of the compensation device. Specifically, each building block power capacitor module 1 has four connection mounting holes on the top and bottom, and multiple bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com