Thin film manufacturing method and manufacturing device

A production method and a technology for producing a device, which are applied to a device for coating liquid on a surface, a spray device, a spray device, etc., can solve problems such as performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

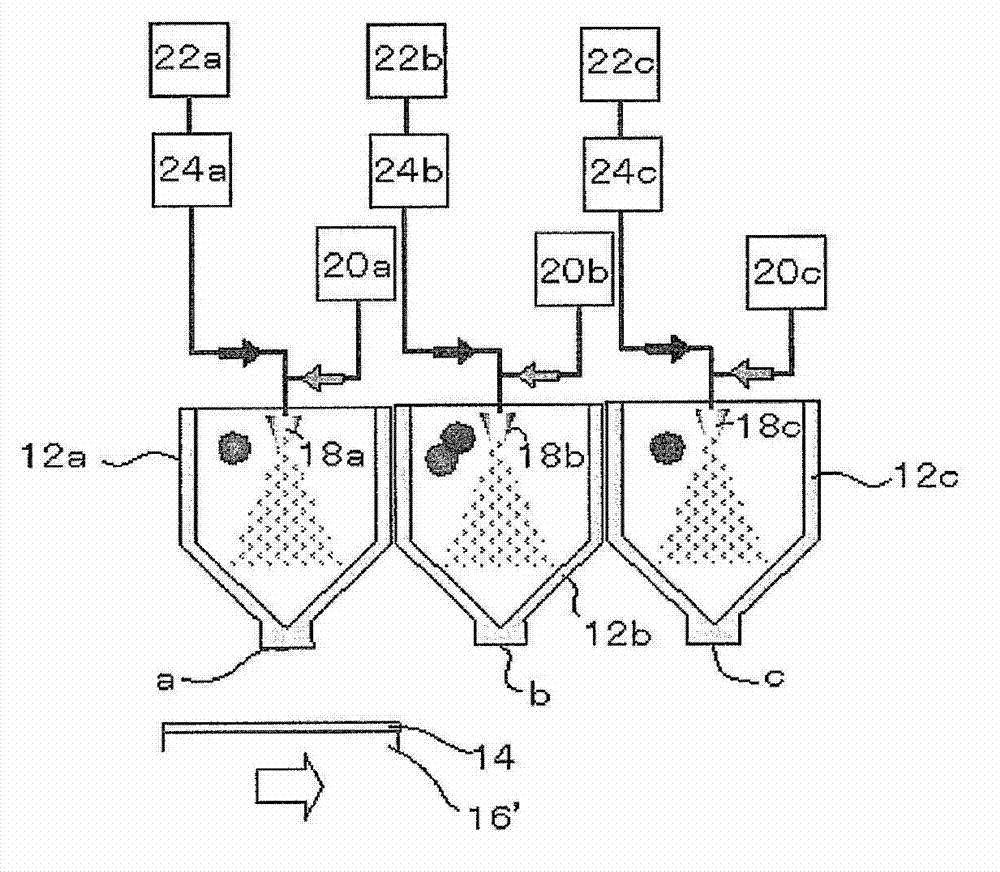

[0304] In Example 1, use and image 3 A film forming apparatus having the same configuration.

[0305] First, the substrate is fixed below the opening a of the chamber 12a, and the raw material solution 1 is sprayed from the two-fluid nozzle 18a in the chamber 12a for 4 minutes to form a lower layer on the substrate, and then the substrate is moved to the opening of the chamber 12b. b, the raw material solution 3 is sprayed from the two-fluid nozzle 18b for 4 minutes to form a mixed layer on the lower layer, and finally, the substrate is moved to the opening c of the chamber 12c, and the raw material solution 2 is sprayed from the two-fluid nozzle 18c in the chamber 12c, An upper layer was formed on the mixed layer to produce a laminated film. The thickness of the formed film was about 0.1 μm.

Embodiment 2

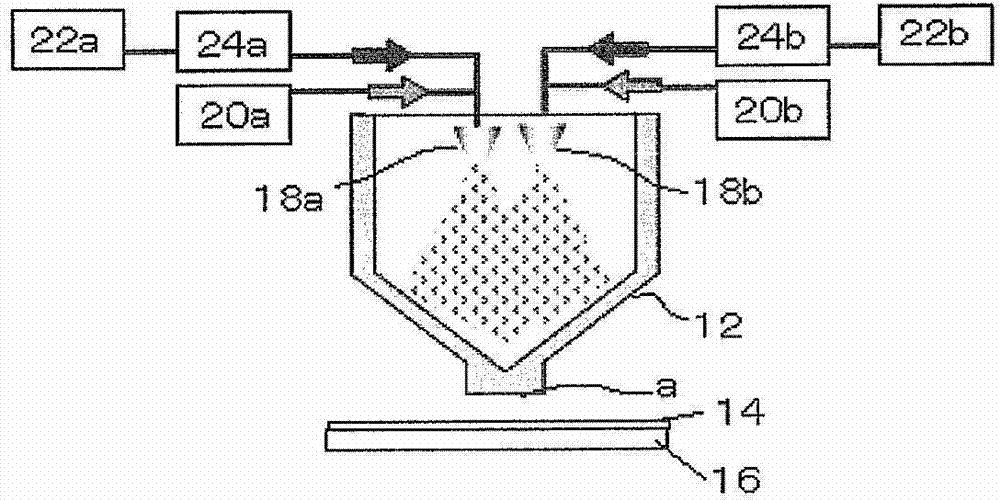

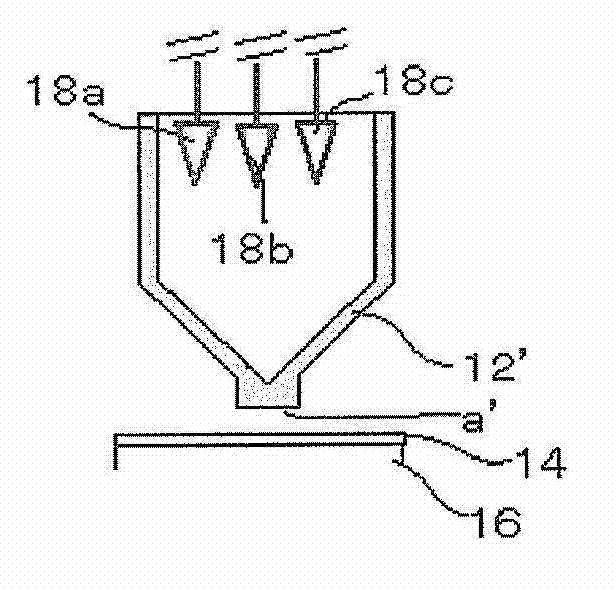

[0307] In Example 2, using figure 2 A film forming apparatus having the same configuration.

[0308] First, the raw material solution 1 is sprayed from the two-fluid nozzle 18a in the chamber 12' for 4 minutes to form a lower layer, then the raw material solution 3 is sprayed from the two-fluid nozzle 18b for 4 minutes to form a mixed layer, and finally, the raw material is sprayed from the two-fluid nozzle 18c Liquid 2 formed the upper layer and produced a laminated film. Meanwhile, the substrate does not move. The thickness of the formed film was about 0.1 μm.

Embodiment 3

[0310] In Example 3, use and Figure 4 A film forming apparatus having the same configuration.

[0311] First, the substrate was fixed below the opening of the chamber 12a', and the raw material solution 1 was simultaneously sprayed for 3 minutes from the three two-fluid nozzles 18a1, 18a2, and 18a3 in the chamber 12a' to form a lower layer on the substrate. Next, while moving the substrate to the lower portion of the opening of the chamber 12b', the raw material solution 1 is sprayed from the two two-fluid nozzles 18b1 and 18b2 in the chamber 12b' for 3 minutes, and the remaining two-fluid nozzle 18b3 is sprayed for 3 minutes. Raw material solution 2. Then, while moving the substrate to the lower portion of the opening of the chamber 12c', the raw material solution 1 is sprayed for 3 minutes from one two-fluid nozzle 18c1 in the chamber 12c', and the two two-fluid nozzles 18c2 and 18c3 are sprayed for 3 minutes. Raw material solution 2. In doing so, a mixed layer is formed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| affinity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com