Patents

Literature

66results about How to "Control status" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

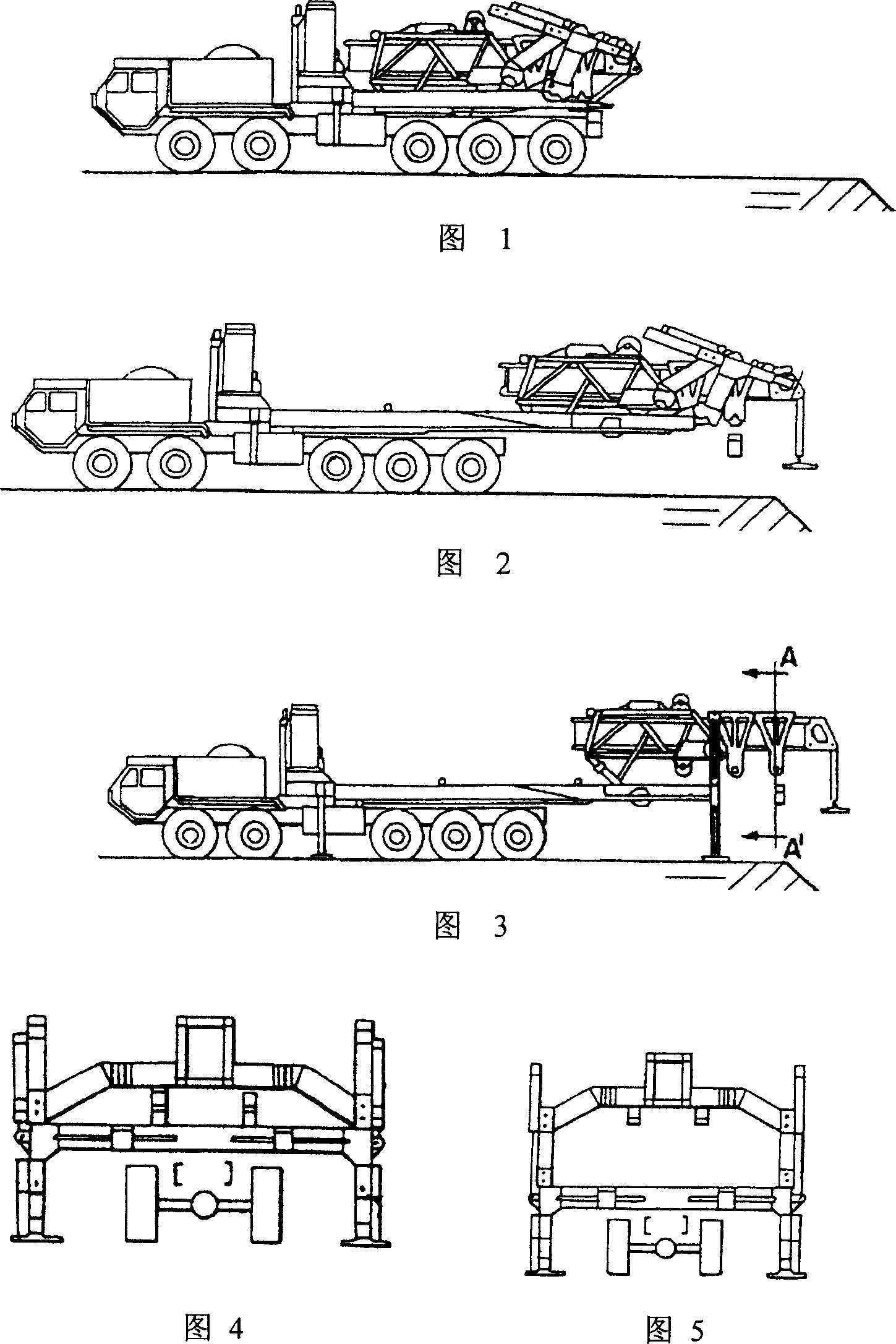

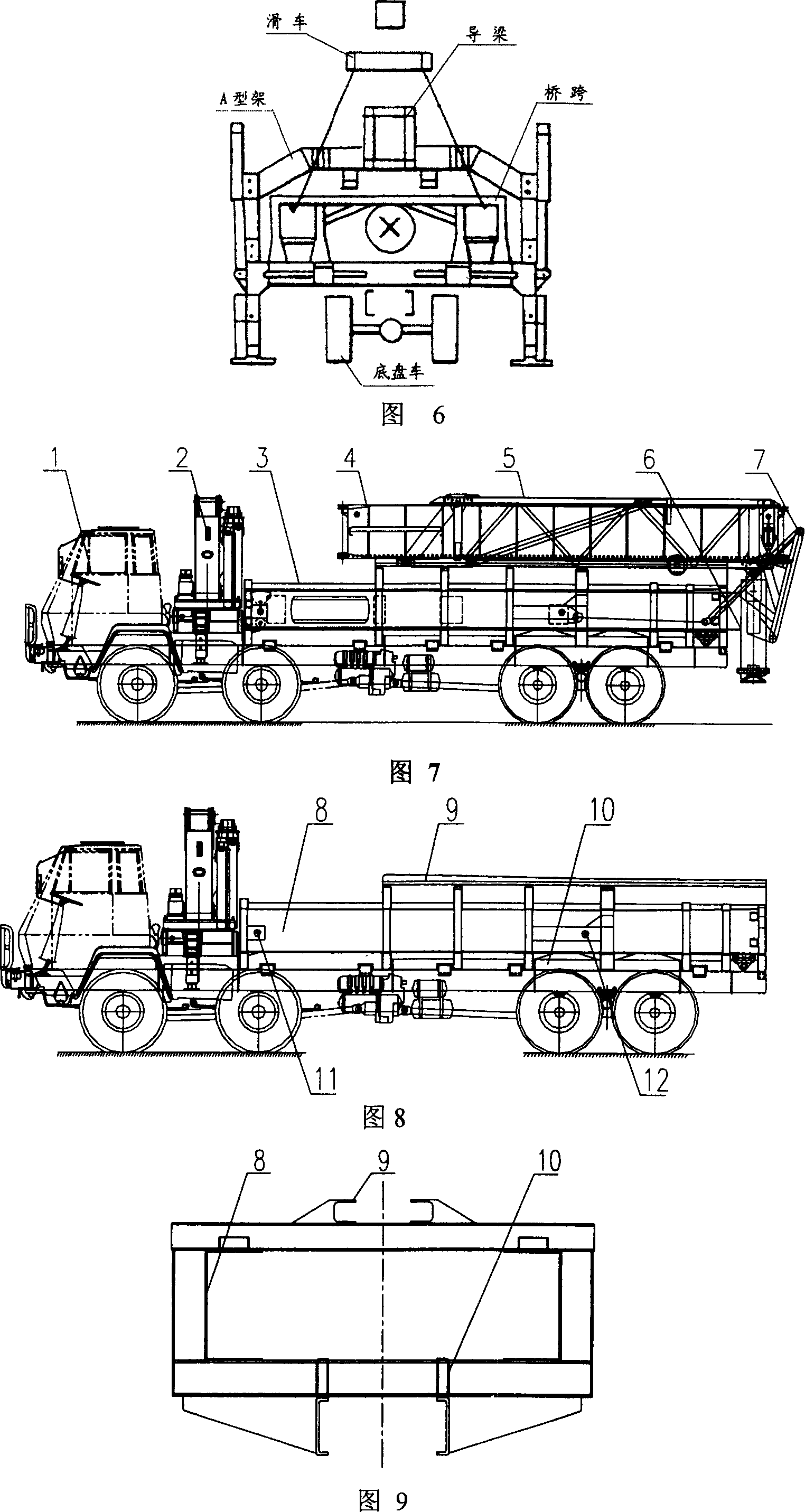

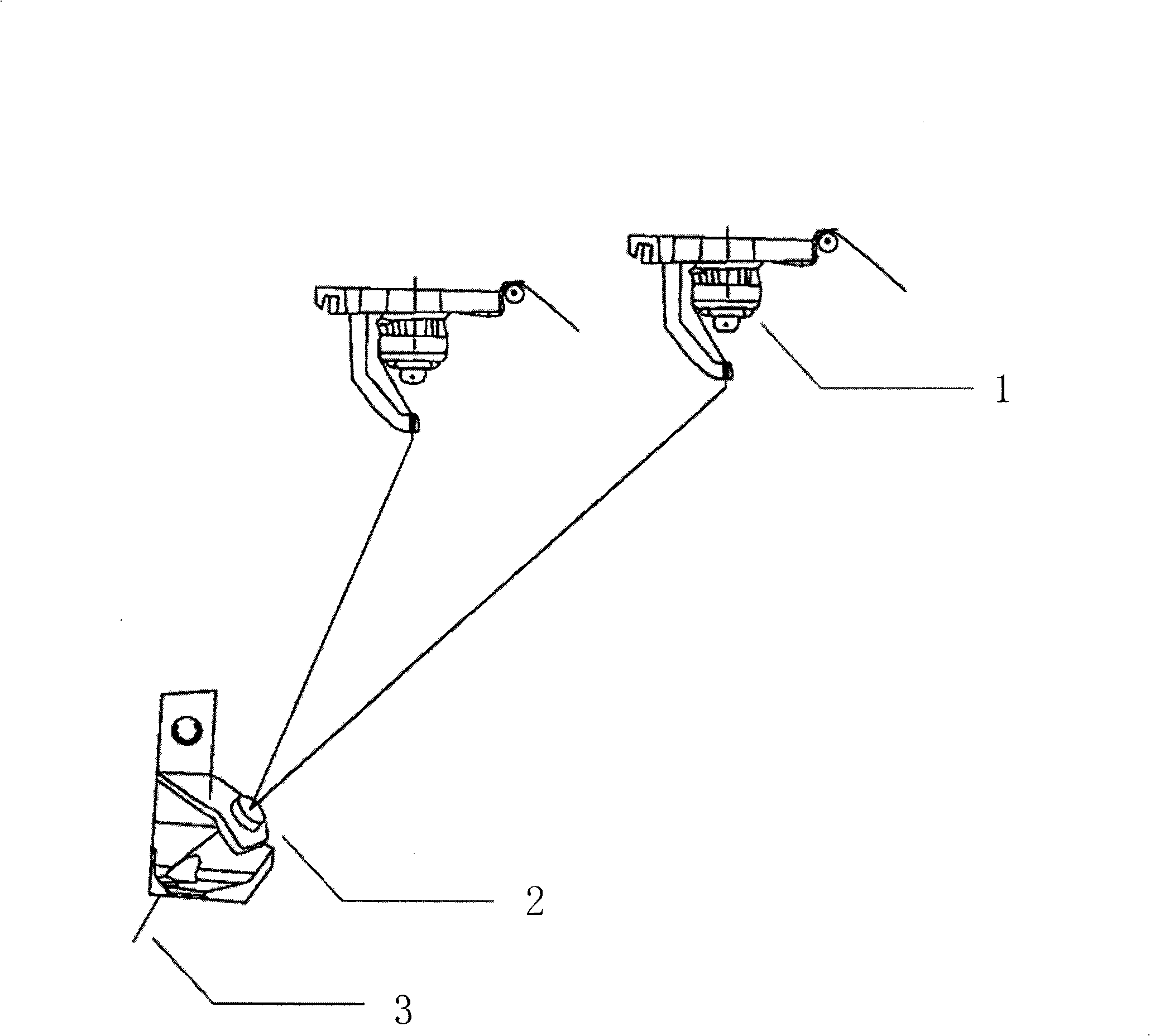

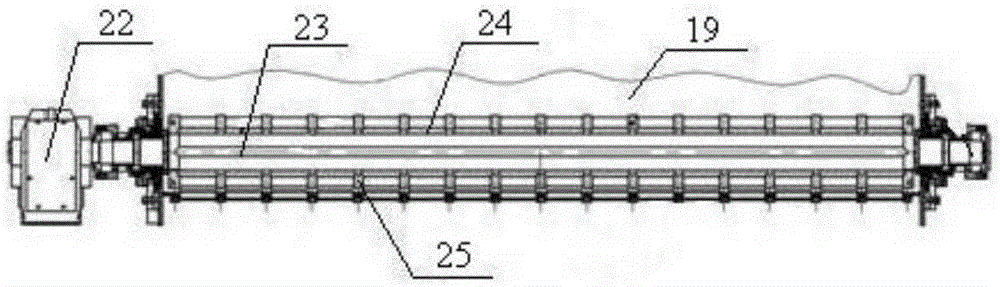

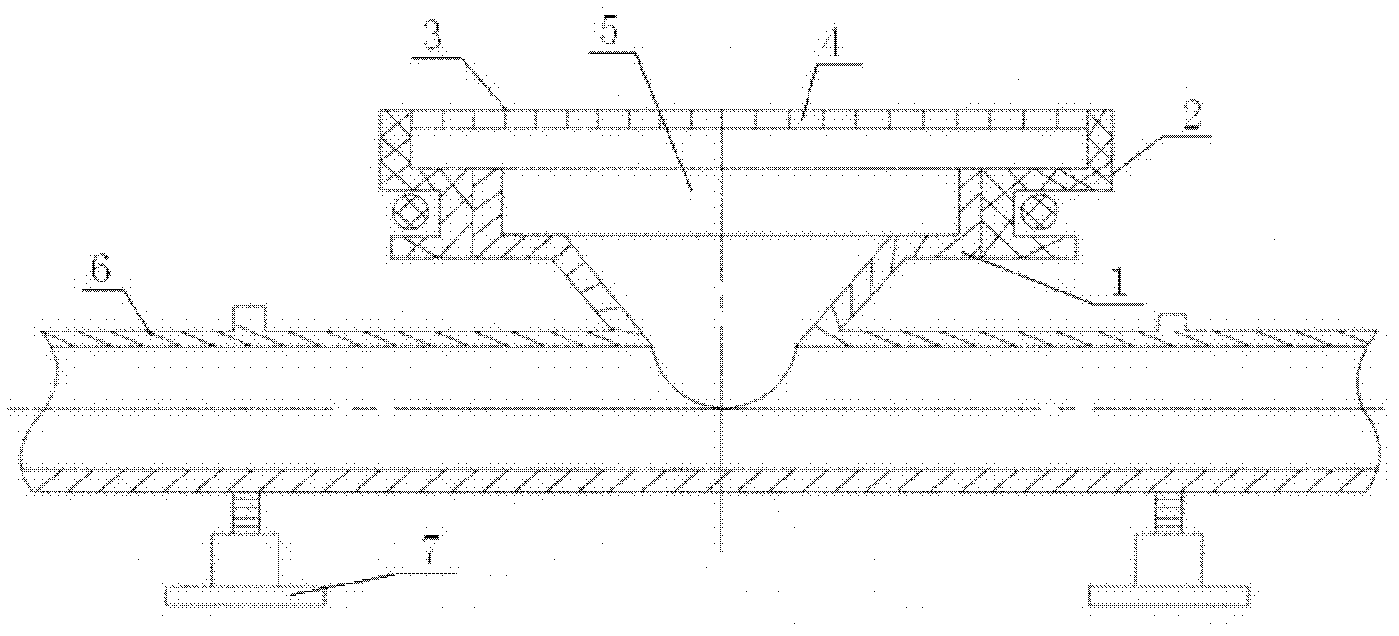

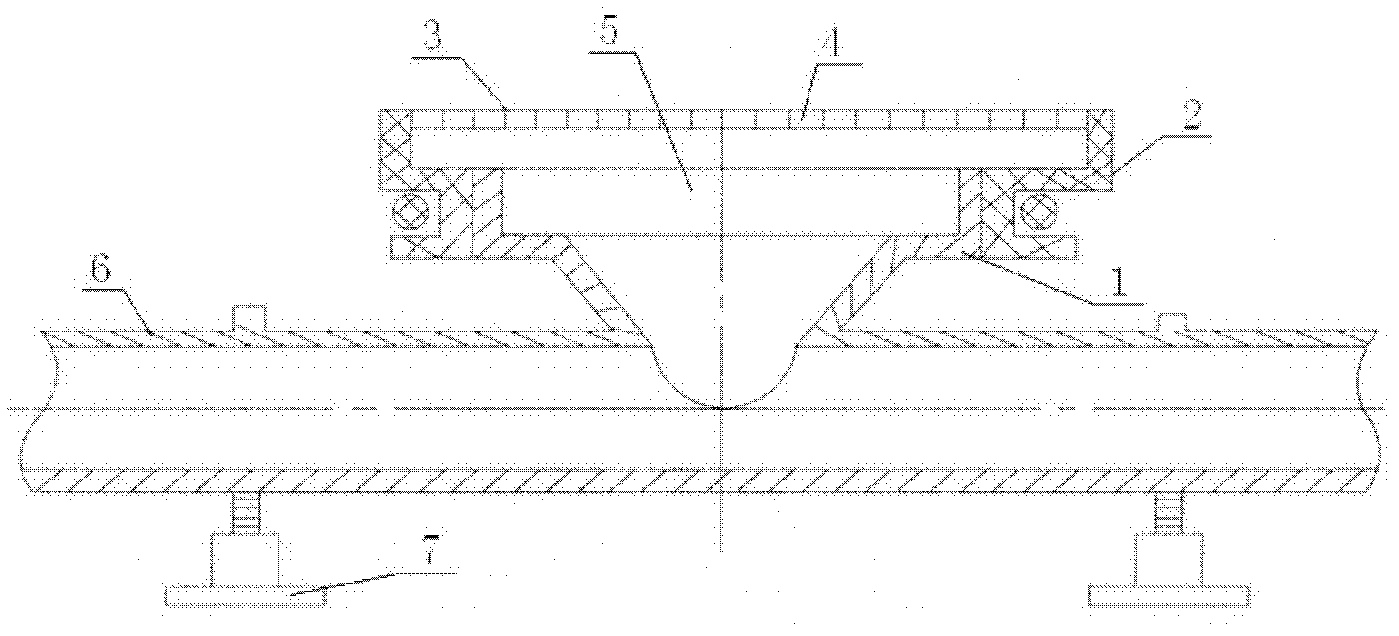

Longspan bridge erecting apparatus and erecting method thereof

InactiveCN100999895ASingle functionImprove reliabilityPortable bridgeBridge erection/assemblyArm foldingLong span

The long span bridge erecting apparatus and process belongs to the field of traffic technology, and is especially suitable for constructing military long span bridge in wartime. The long span bridge erecting apparatus consists of chassis, arm folding crane, erecting platform, leading-in girder unit, leading-in girder sheath, movable stand, chassis frame and bridge section. The long span bridge erecting apparatus has lowered erecting height, convenient transportation, composite structure and high reliability. The present invention has short construction period, low operation plane and relatively simple construction and other advantages.

Owner:邹煜 +7

General distributed crawler system capable of automatically detecting shielding

InactiveCN103491165AEasy to addEasy to removeMultiprogramming arrangementsStar/tree networksNetwork structureSmart technology

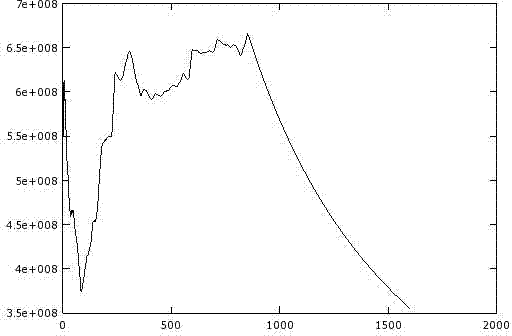

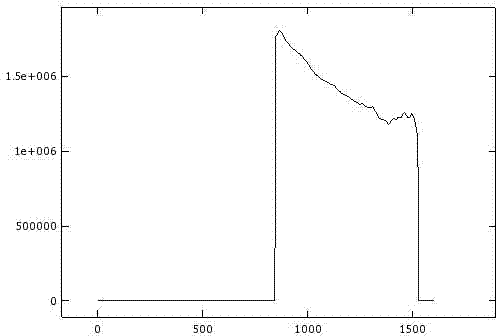

The invention belongs to the technical field of distributed systems and artificial intelligence, and particularly relates to a general distributed crawler system capable of automatically detecting shielding. The system is of a star-type network structure and comprises a core node Master and a plurality of Slaves. The core node Master controls the Slaves in a cluster. According to the general distributed crawler system capable of automatically detecting the shielding, an algorithm for detecting a shielded page in a full-automatic mode is adopted, and whether an abnormal situation occurs or not is detected by detecting the size of the page downloaded by crawlers and the randomness of the distribution of Token editing distances so as to automatically distinguish whether the current obtained page is effective data or not. According to the general distributed crawler system, whether each Slave in the current cluster is shielded or not can be automatically distinguished so as to conduct better task scheduling, and therefore the Slave resources and network resources are utilized to a greater extent.

Owner:FUDAN UNIV

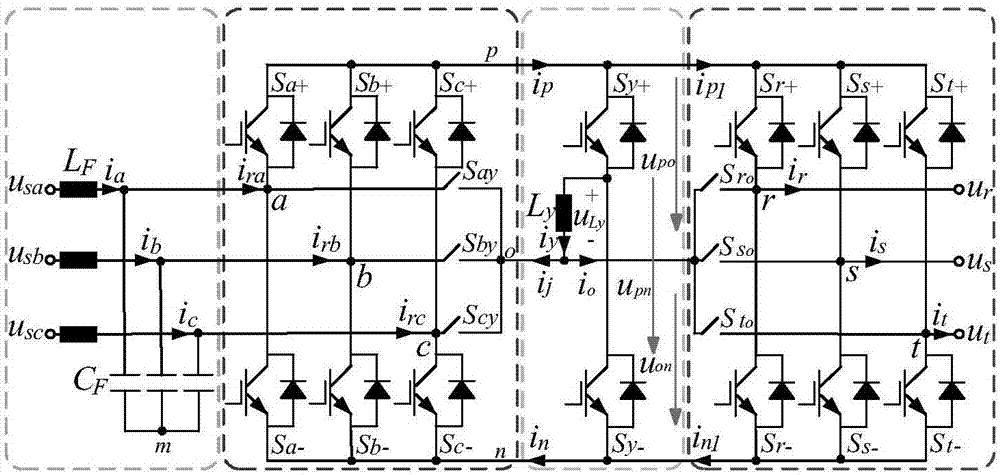

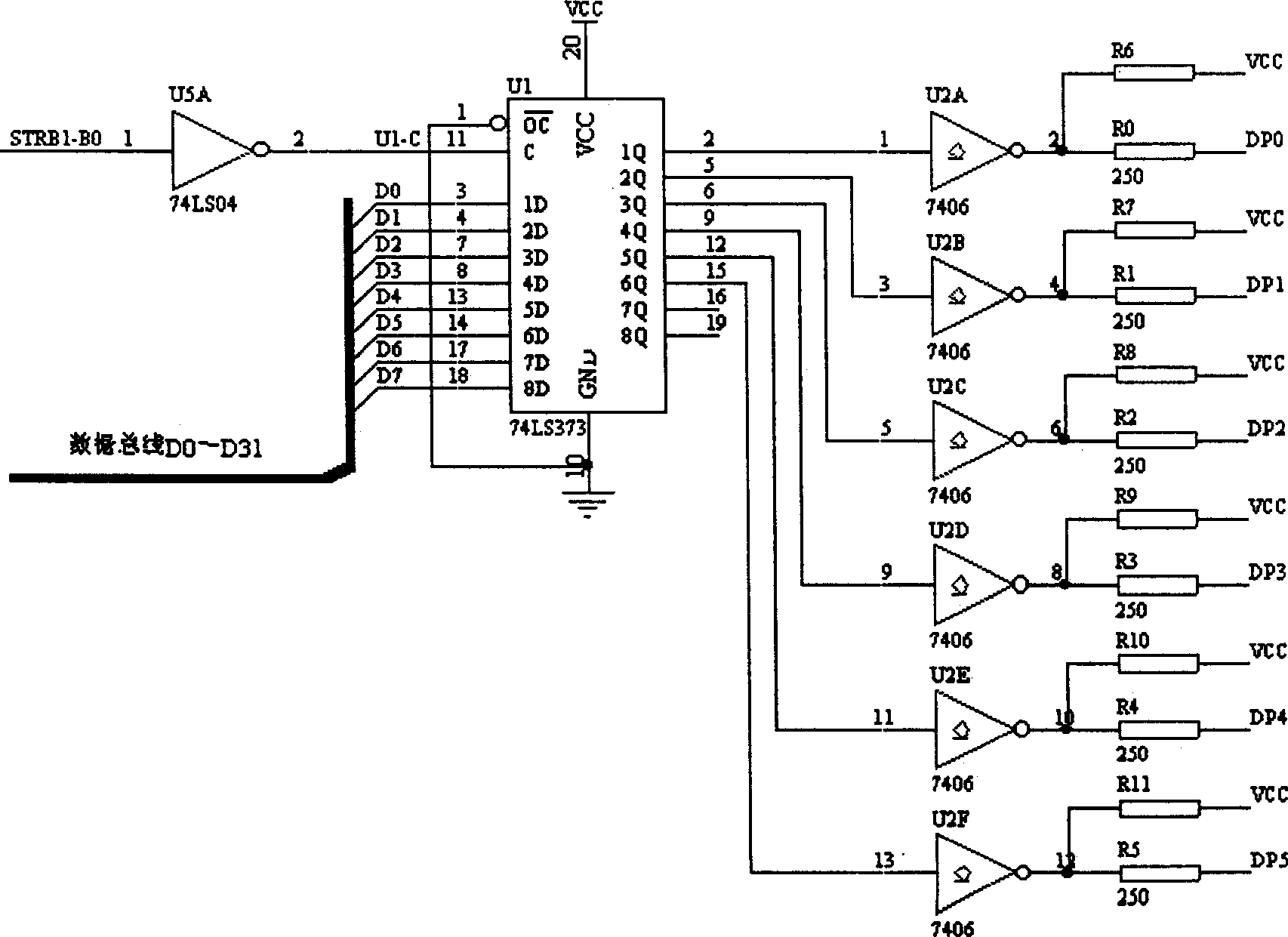

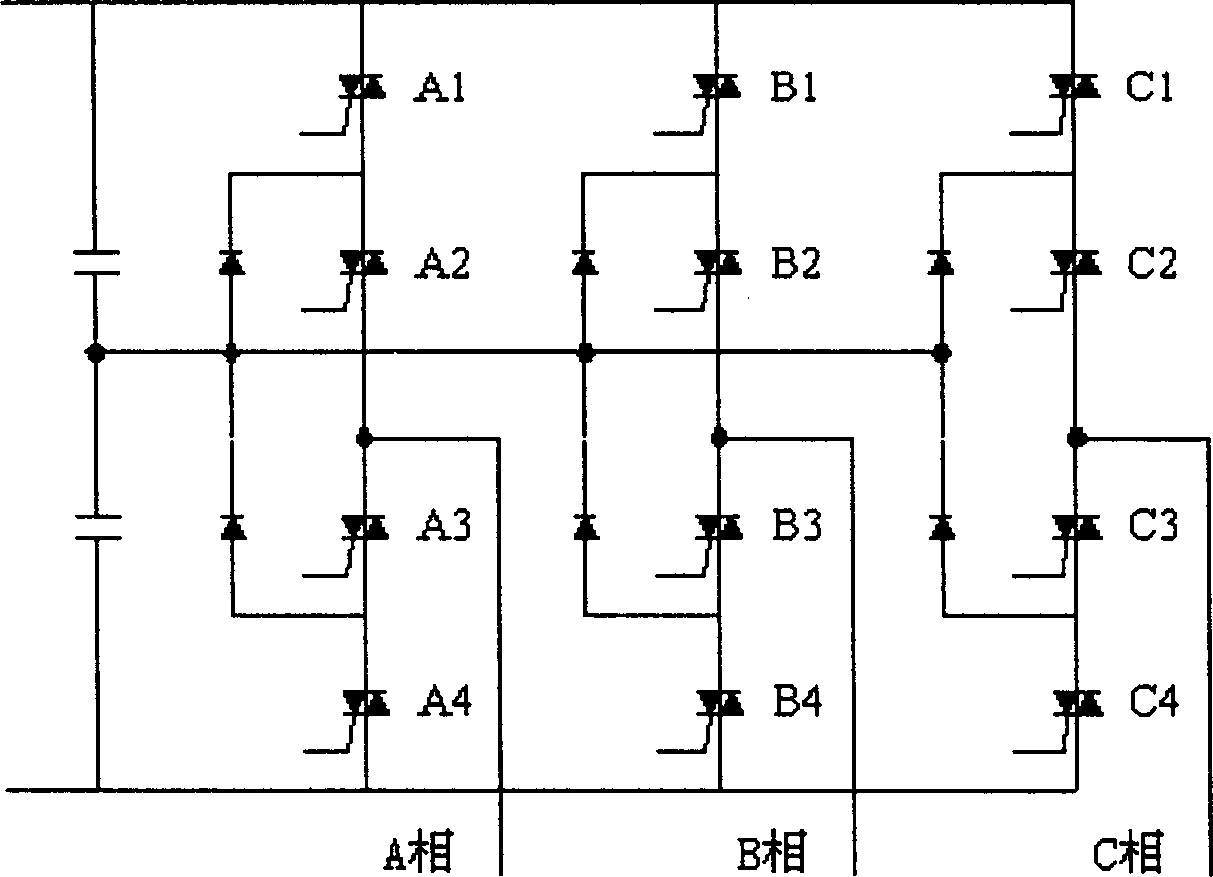

Three-level indirect matrix converter and control method

InactiveCN107204714AGuaranteed self-balancingQuality improvementAc-ac conversionThree levelMatrix converters

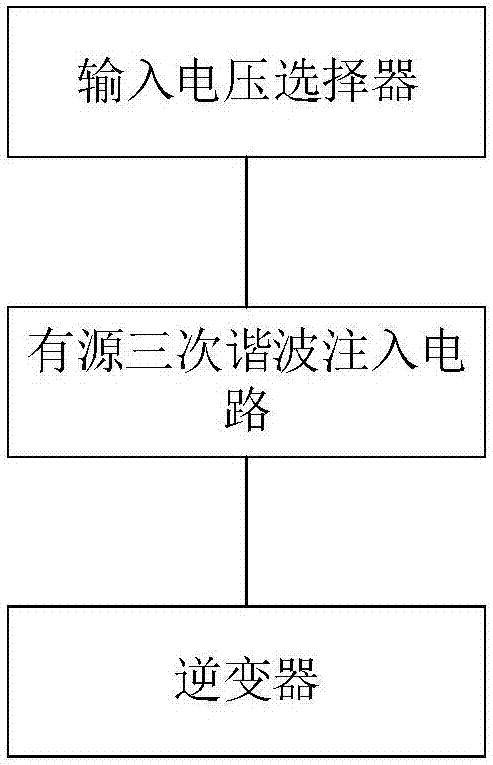

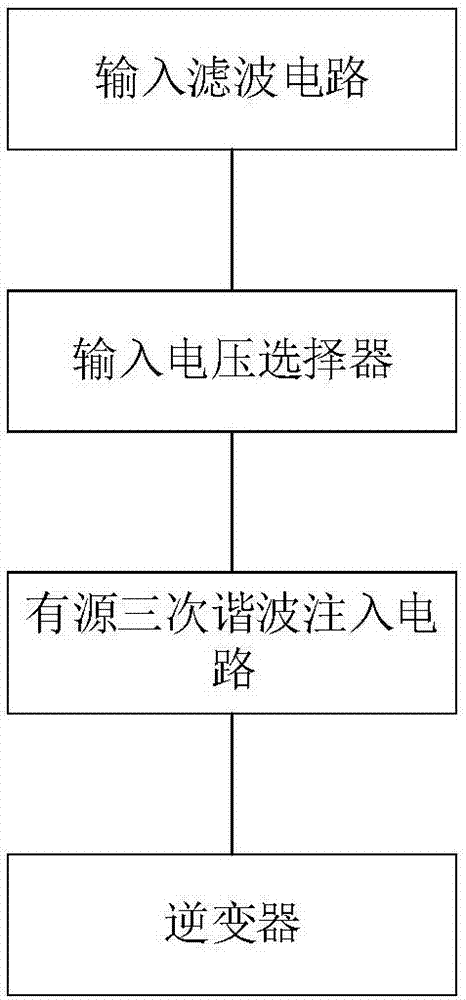

The invention provides a three-level indirect matrix converter and a control method. The three-level indirect matrix converter comprises an input voltage selector, an active triple-harmonic injection circuit and an inverter, wherein the input end of the input voltage selector is connected with a three-phase alternating current power supply, and the output end of the input voltage selector is connected with positive and negative electrode direct current buses; the upper and lower ends of the active triple-harmonic injection circuit are connected with the positive and negative electrode direct current buses respectively, and a third end of the active triple-harmonic injection circuit is connected with the input end of the input voltage selector and the output end of the inverter; the upper and lower ends of the inverters are connected with the positive and negative electrode direct current buses respectively, and the output end is connected with a load. Triple harmonic injection induction currents are generated through the active triple-harmonic injection circuit and injected into the input voltage selector and the inverter respectively, so that the average current of the neutral point is kept to be zero, self-balance of voltage of the neutral point is further guaranteed, and the quality of input and output waveforms is improved.

Owner:CENT SOUTH UNIV

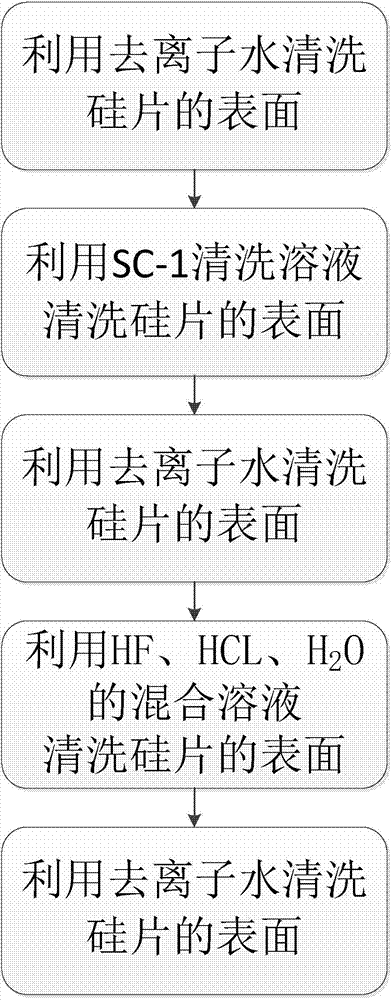

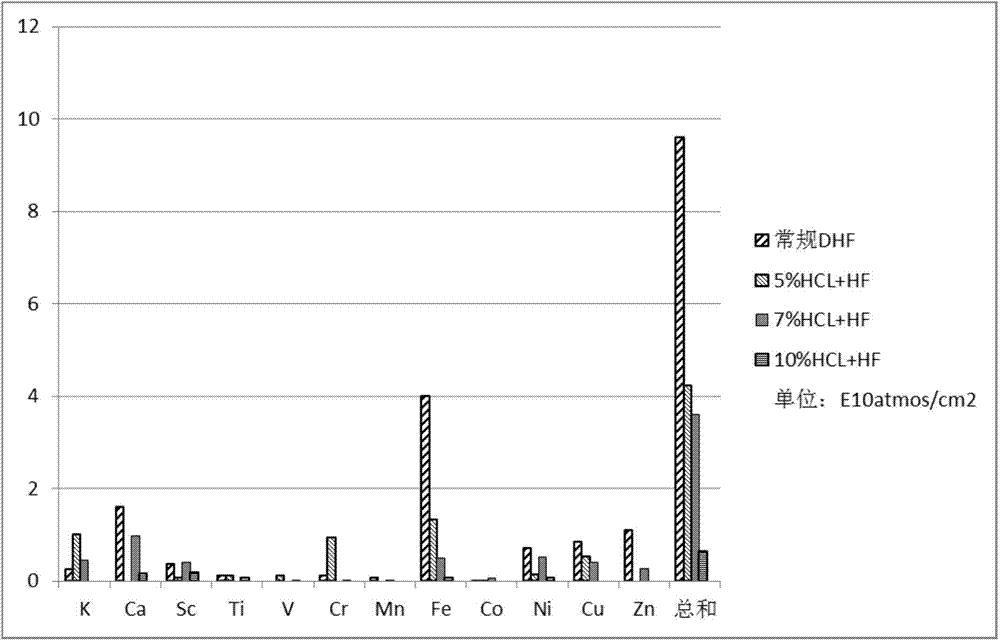

Silicon wafer cleaning process

InactiveCN103762155AEfficient removalInhibition of reattachmentSemiconductor/solid-state device manufacturingCleaning using liquidsSiliconMetal

The invention discloses a silicon wafer cleaning process. The silicon wafer cleaning process comprises the following steps of (1) using deionized water to clean the surface of a silicon wafer, (2) using an SC-1 cleaning solution to clean the surface of the silicon wafer, (3) using deionized water to clean the surface of the silicon wafer, (4) using a mixed solution containing HF, HCL and H2O to clean the surface of the silicon wafer, and (5) using deionized water to clean the surface of the silicon wafer. According to the silicon wafer cleaning process, due to the fact that the HCL is added to DHF, acidity of the DHF is improved, the metal attachment phenomenon in cleaning fluid cannot easily happen in the high-acidity solution, and the high capacity of removing metal on the surface of the silicon wafer is achieved; compared with a DHF process, the silicon wafer cleaning process has the three advantages that Na, K, Ca, Mg and Al can be further and effectively removed through the HCL; the PH value of the solution of the HCL is lowered, the state of metal complexing ions in the cleaning fluid is controlled, and reattachment of metal is inhibited; the content of Cu2O and the content of CuO on the surface of the silicon wafer can be reduced, and thus the content of Cu on the whole surface of the silicon wafer is controlled.

Owner:SHANGHAI SHENHE THERMO MAGNETICS ELECTRONICS CO LTD

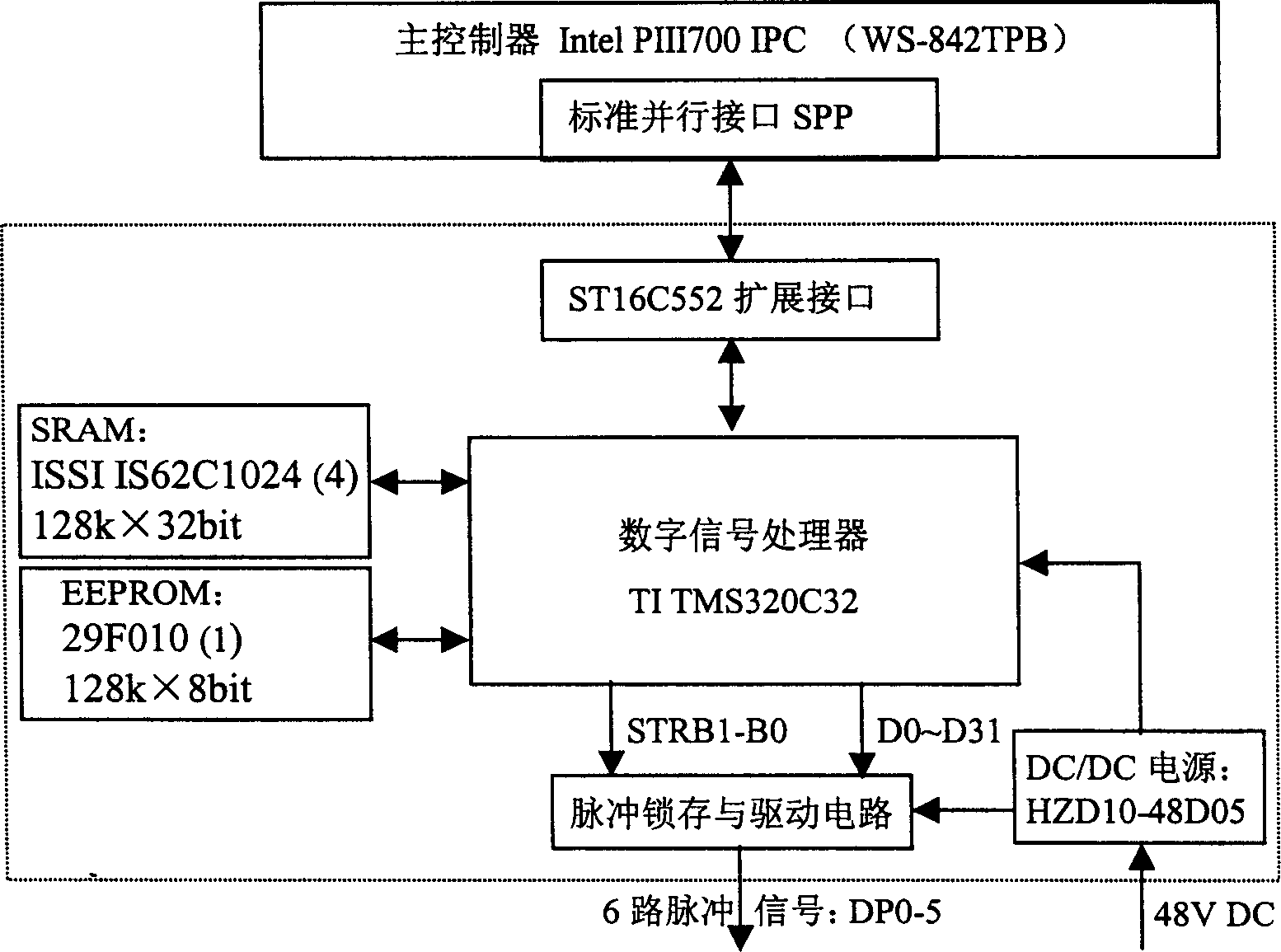

Generating method of three-level harmonic-trapping width-modulation pulse and pulse generator

The present invention relates to AC / DC / AC frequency-varying speed regulating technology. The present invention includes the steps of: generating switching pulse sequence in required format based on the required switching function modulation ratio and pulse frequency, receiving and judging the control command word of monitoring host computer, generating and sending six channel pulse sequence for normal control based on the required modulation ratio and pulse frequency and other steps. Then, is proposed three-level harmonic-trapping modulation pulse generator based digital signal processor. Thepresent invention is suitable for high and middle voltage frequency-varying speed regulator and can elimiante high order harmonics, reduce switching loss, prolong the life of switching device and ensure enough output power.

Owner:ZHONGSHAN MINGYANG ELECTRIC

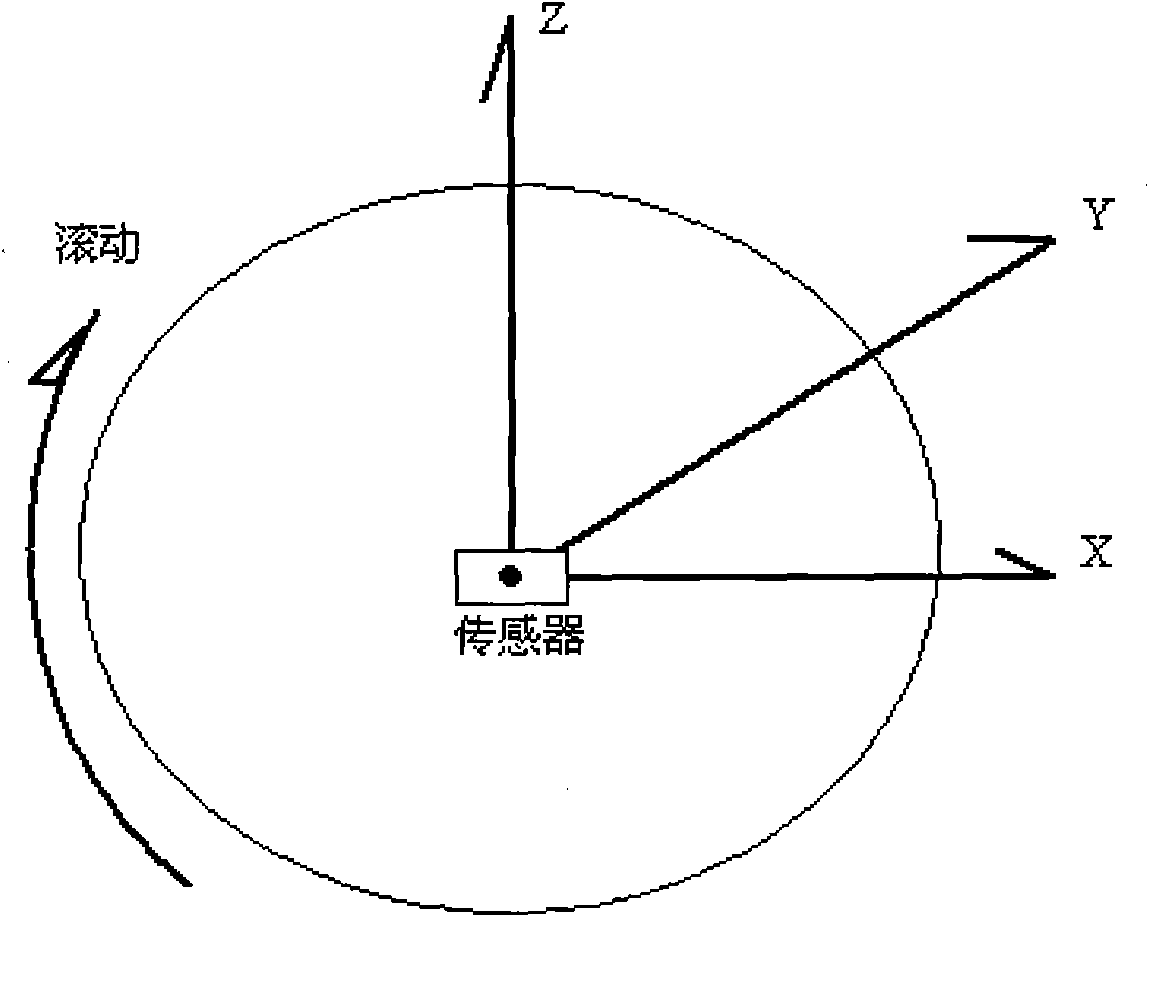

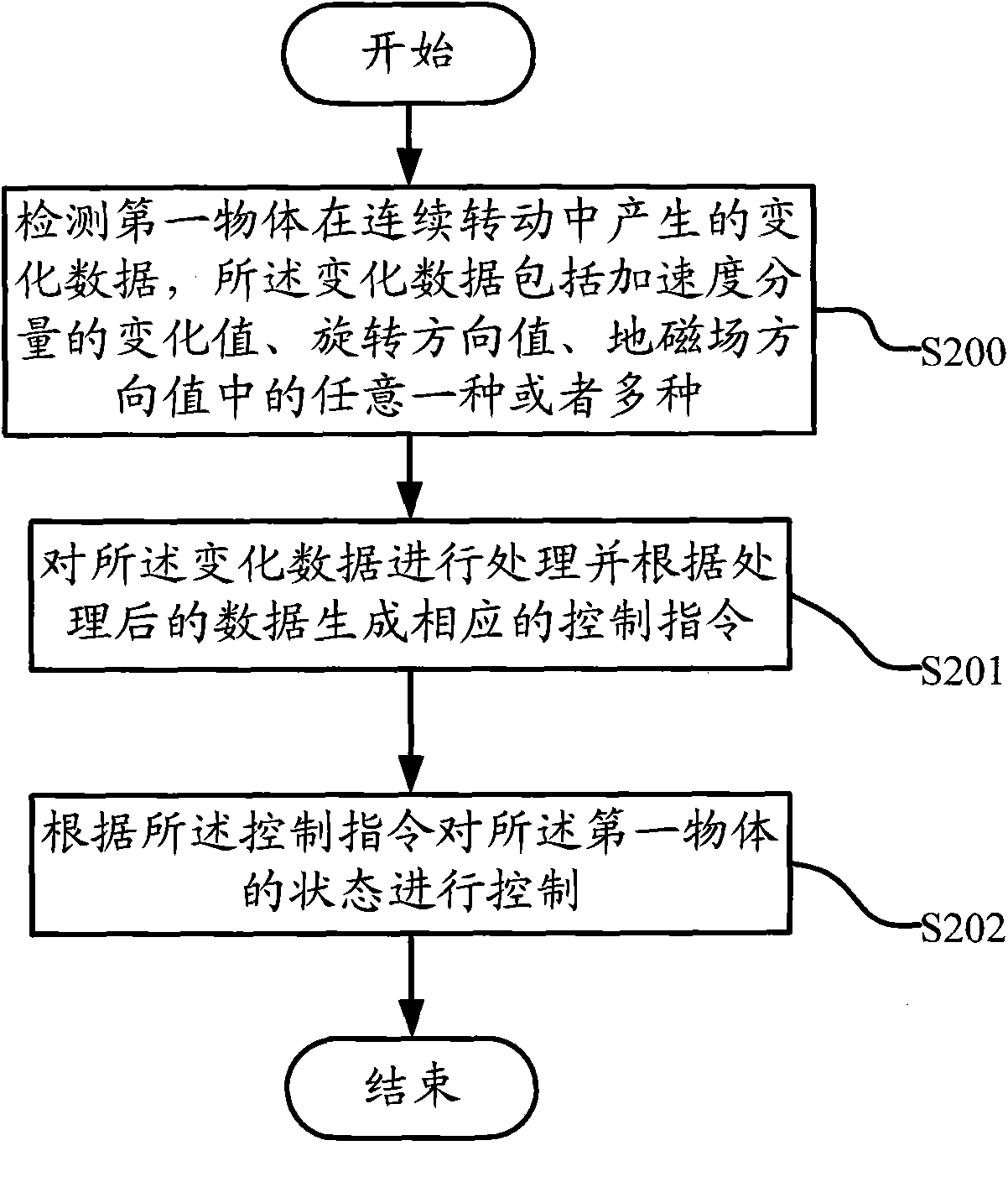

Control method, device and system thereof

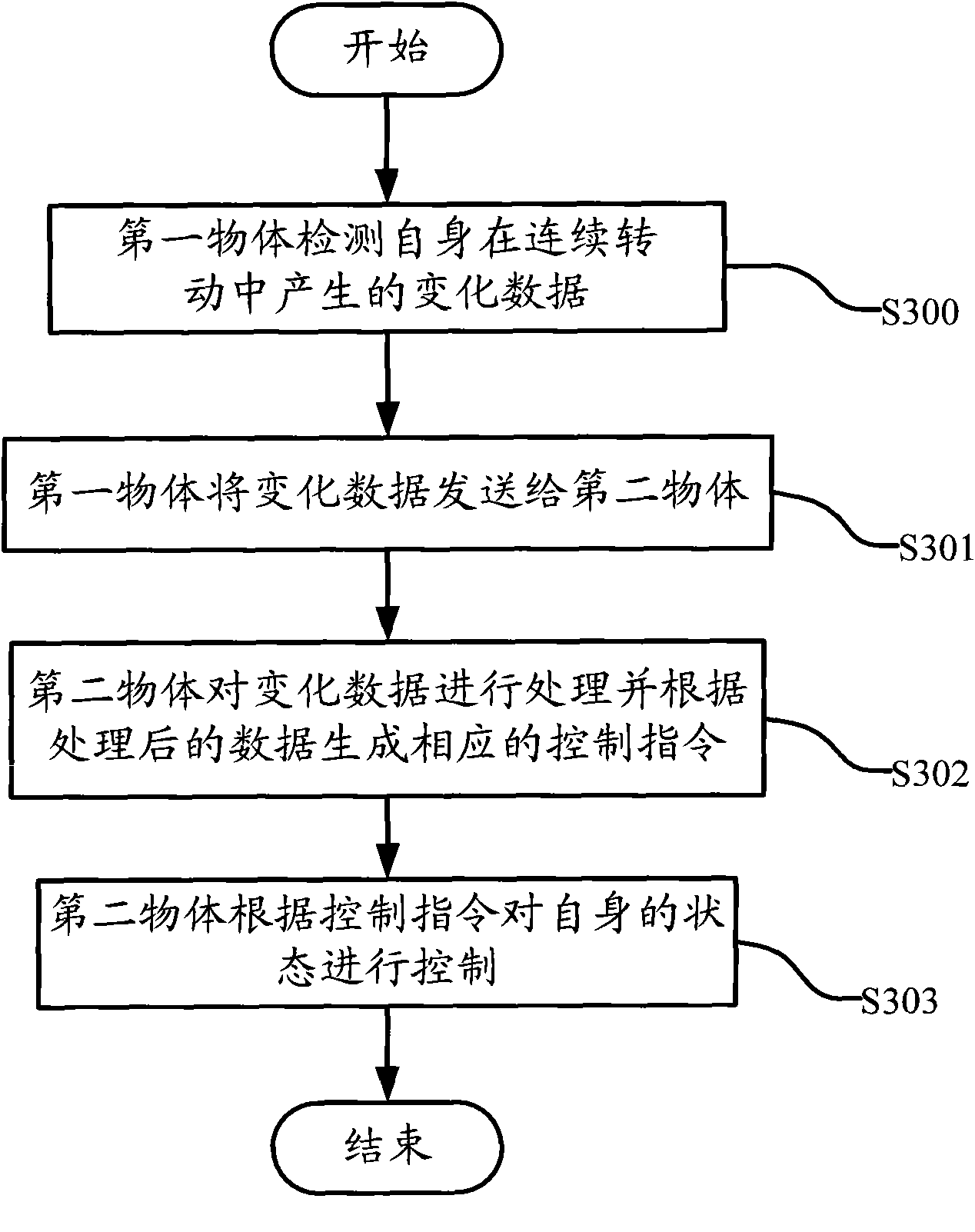

InactiveCN101799725AControl statusAccurate detectionInput/output processes for data processingControl systemComputer science

The embodiment of the invention discloses a control method, a control device and a control system. The control method comprises the following steps: detecting changed data when a first object is continuously rotated, wherein the changed data is any one or more of a variation value, a rotational direction value and a geomagnetic field direction value of an acceleration component; processing the changed data and generating a corresponding control instruction according to the processed data; and controlling the state of the first object according to the control instruction. The method also can comprise the following step: sending the changed data to a second object so as to enable the second object to control the state of the second object. The rotation of the continuous rotation is one or more of rotation, rolling and tumbling. In the embodiment of the invention, the corresponding control instruction is generated according to the changed data when the object is continuously rotated which is detected by a sensor, a moving object can be detected accurately, the power consumption of detection can be reduced, and the state, the display and the movement of the object can be controlled accurately.

Owner:罗富强

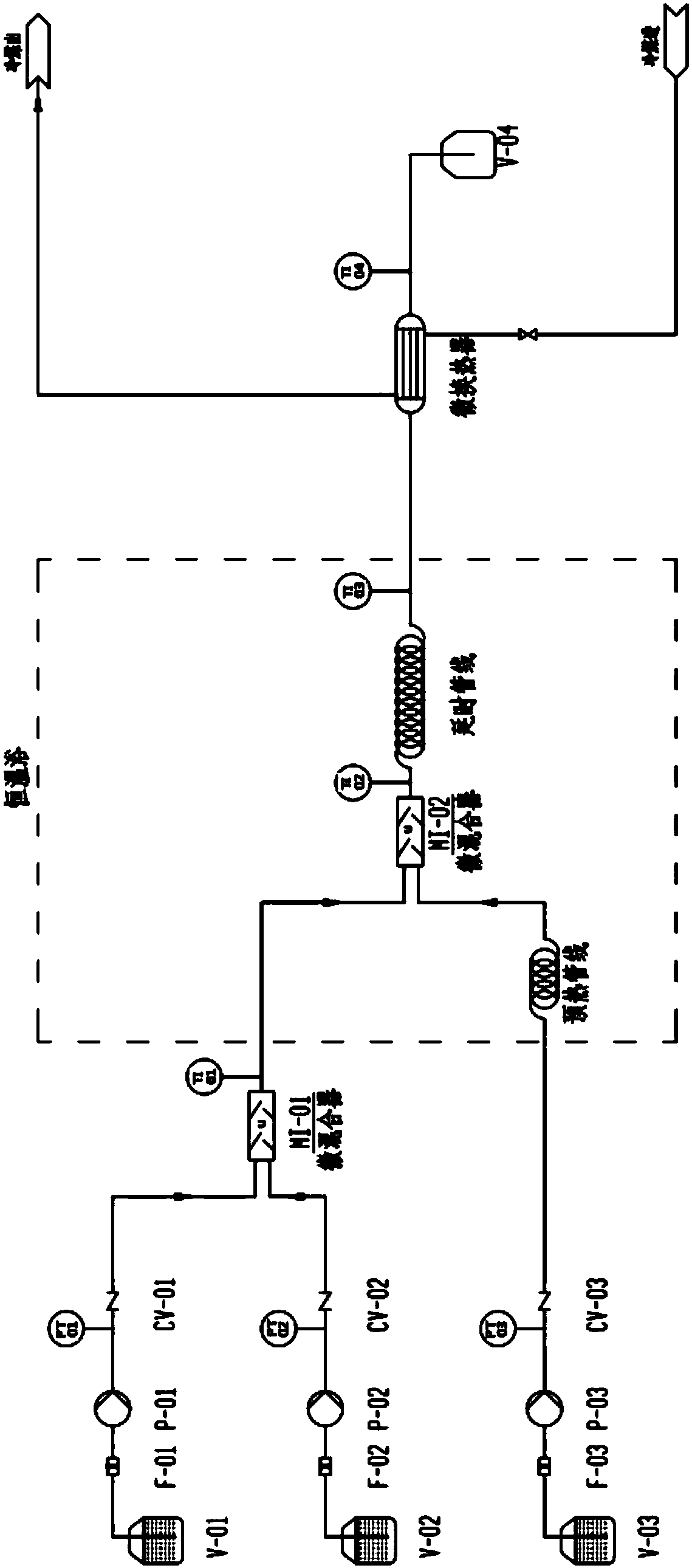

Method for performing aldol condensation reaction in micro-channel reactor

InactiveCN108191592AAvoid contactToxicOrganic compound preparationOrganic chemistry methodsEquivalence ratioKetone

The invention relates to a method for performing an aldol condensation reaction in a micro-channel reactor. The aldol condensation reaction is performed in the micro-channel reactor under the action of a catalyst at 60 to 170 DEG C and 0 to 5 MPa in the situation that alpha-H aldehyde ketone and other aldoketones in molecules are in the molar ratio of 0.8-1.2:1. According to the aldol condensationreaction involved in a process provided by the invention, the reaction time is shortened by thousands of times; the raw material conversion rate and the product selectivity are improved by 15 percentat least. The process provided by the invention can realize instantaneous uniform mixing; the equivalence ratio of materials in a reaction process is reduced; the using amount of a catalyst in a reaction process is reduced; Cannizzaro side reactions and polymerization reactions are reduced. The process provided by the invention also reduces the use of some additional solvents so as to reduce theproduction cost; the process provided by the invention also improves the safety of a reaction process, so that the types of reactions are safer and more environment-friendly; meanwhile, the micro-channel reactor used by the process provided by the invention is small in occupied area and high in capacity, so that the production efficiency and the production capacity are greatly improved.

Owner:DALIAN WONDERSUN BIOCHEM TECH

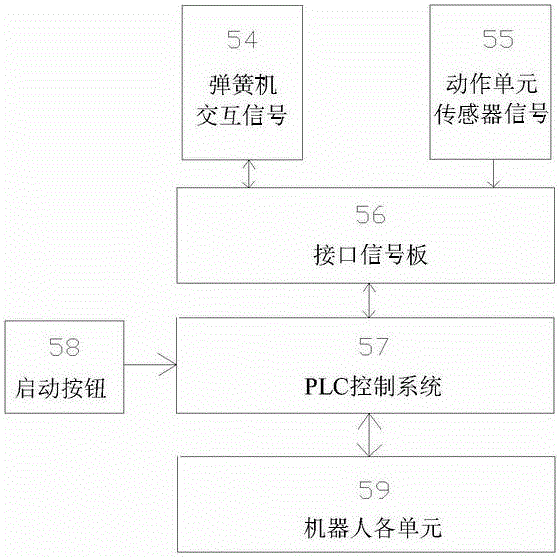

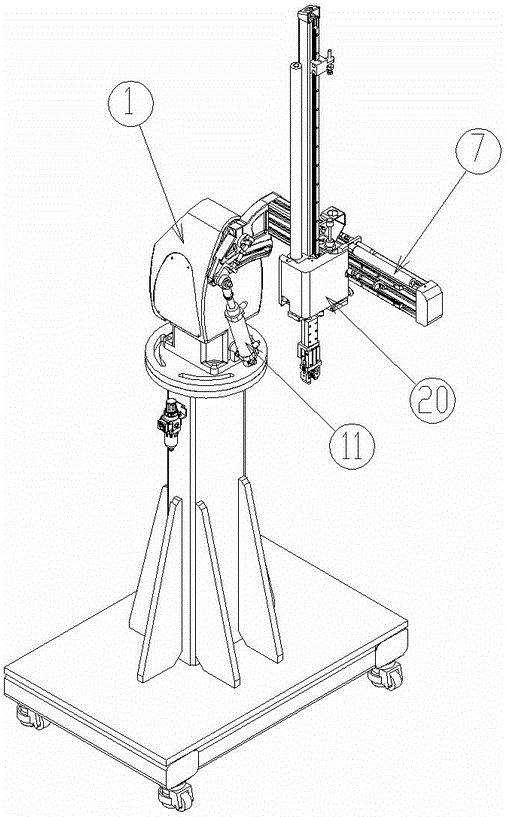

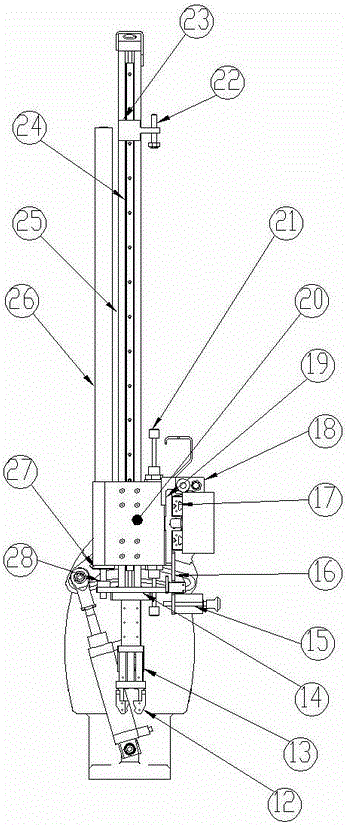

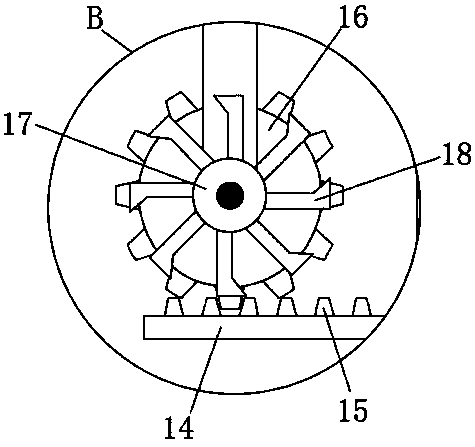

Robot for taking out springs

InactiveCN106426131AEasy to controlControl statusProgramme-controlled manipulatorControl systemPiston rod

A robot for taking out springs is used for taking out the springs from a spring machine. A cylinder barrel of a second air cylinder is fixed to a machine body, a piston rod is connected with one end of a rotational flange, the other end of the rotational flange is connected with a transversal shaft, the rotational flange is connected with the machine body through a rotational standard shaft, the piston rod of the second air cylinder is ejected out, and the rotational flange rotates around the rotational standard shaft so that the transversal shaft can be overturned with a vertical shaft; a first air cylinder drives a connection block of the vertical shaft to do horizontal movement on a transversal guide rail, and a third air cylinder drives the vertical shaft to do vertical movement on a vertical guide rail; a hand claw is a folio staggering tooth hand claw; foma wheels which can achieve rapid positioning and fixing of the robot are installed on the bottom of a bottom plate; and external signals are connected with a PLC control system through an interface signal plate, and after receiving signals of a start button, the PLC controls units of the robot to act. By means of the robot, an operator only needs to package and move the arranged springs out, the working efficiency is high, fast and accurate alignment can be achieved, the system compatibility is high, the grabbing mass of the hand claw is large, and the clamping effect is good.

Owner:XIANGYANG GANGDUOLI INTELLIGENT TECH CO LTD

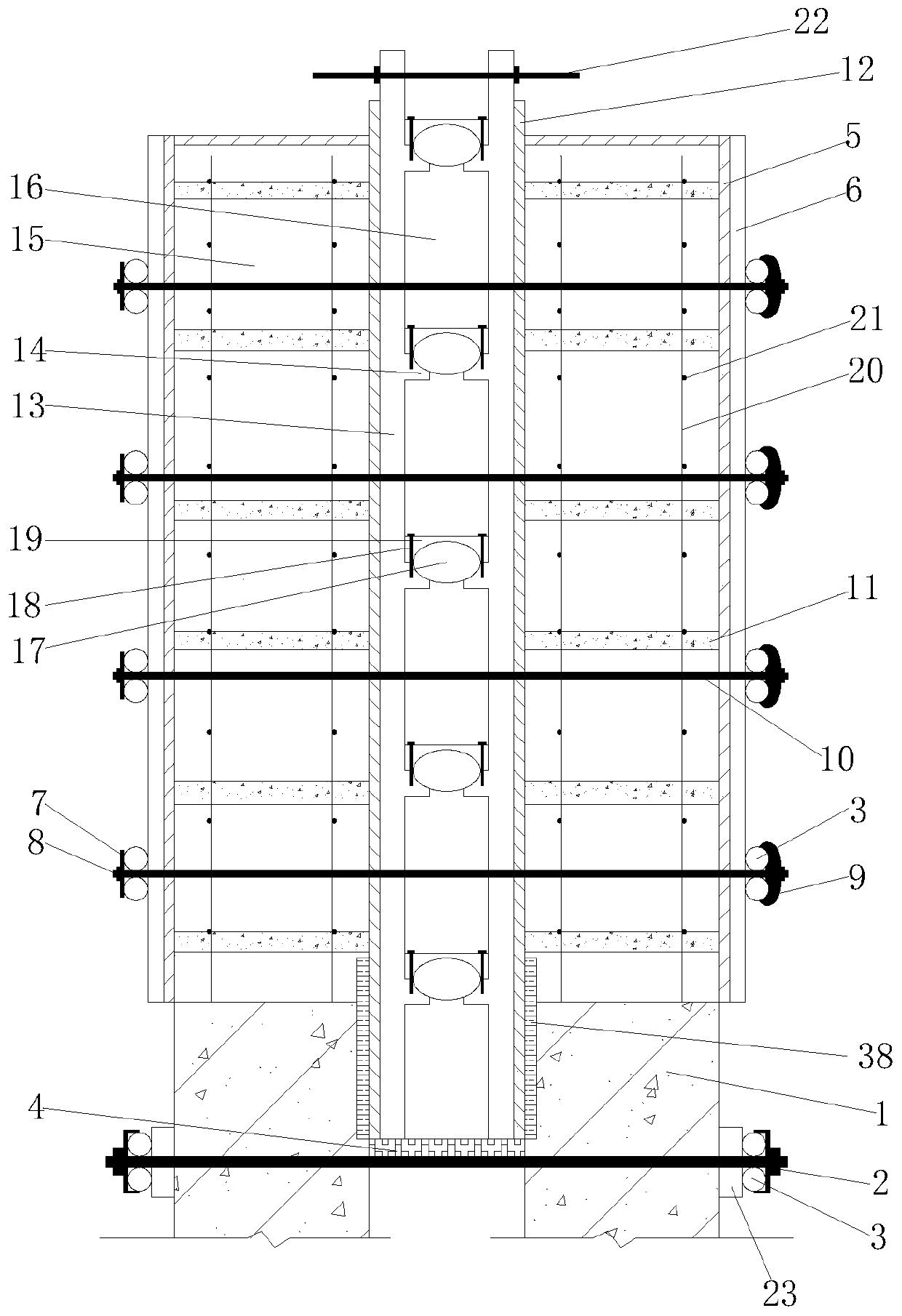

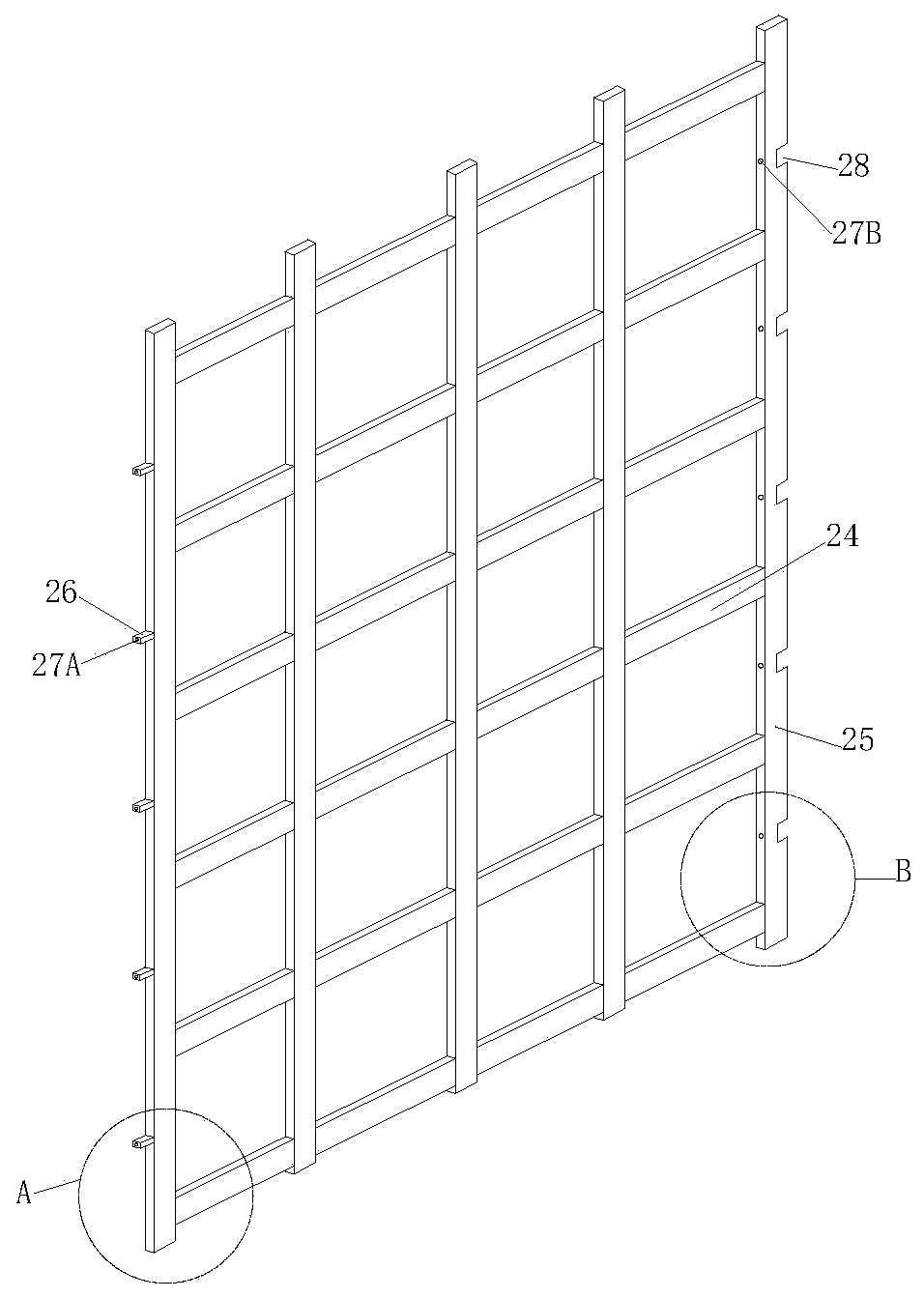

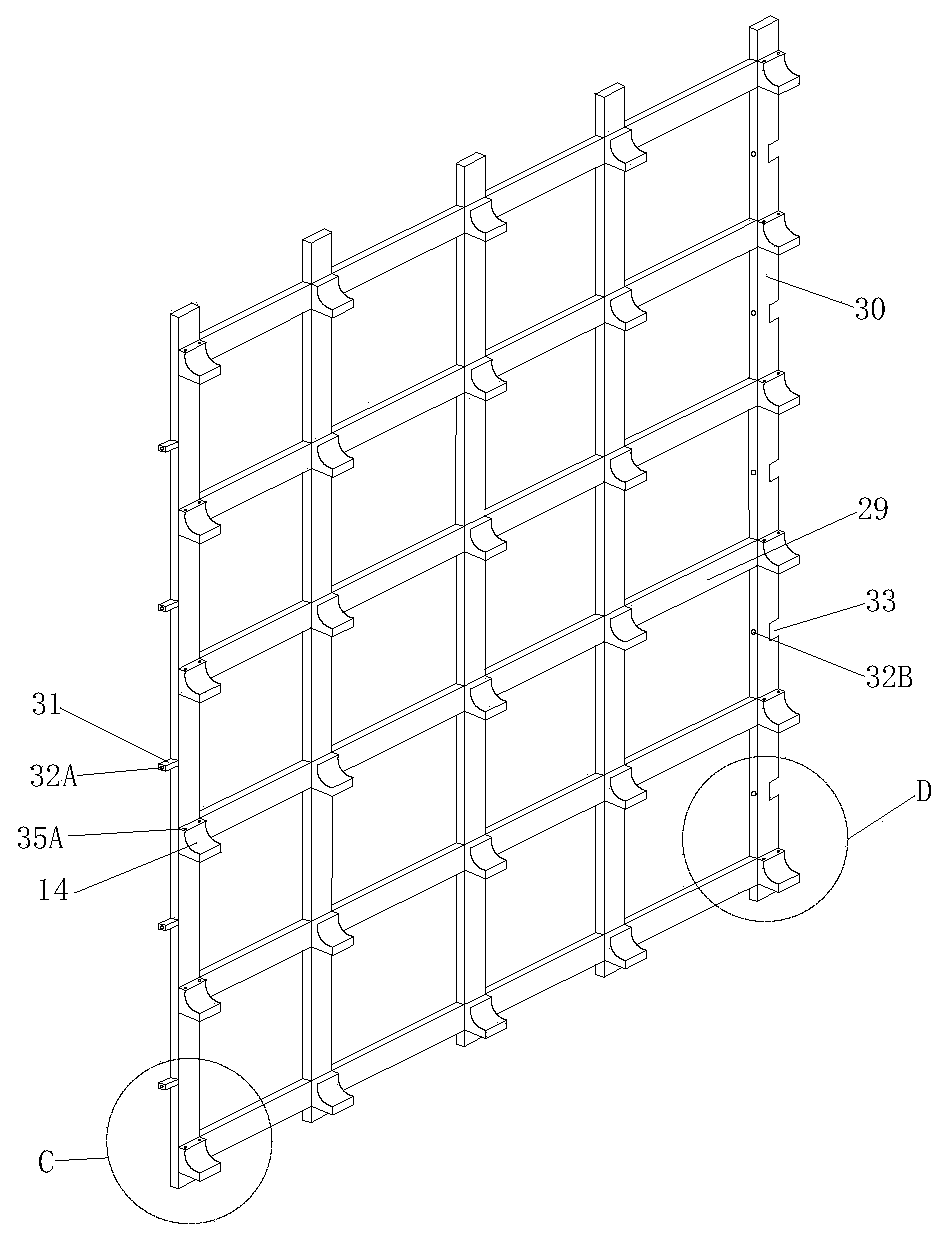

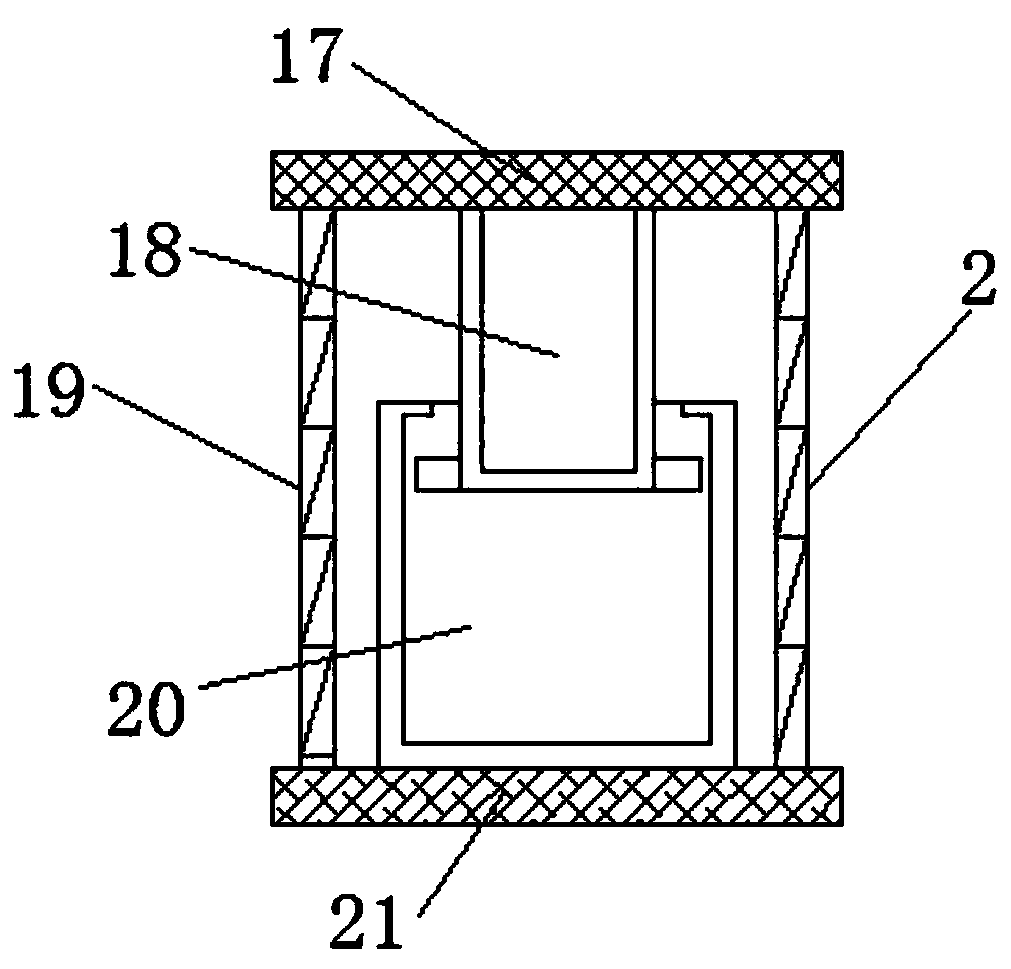

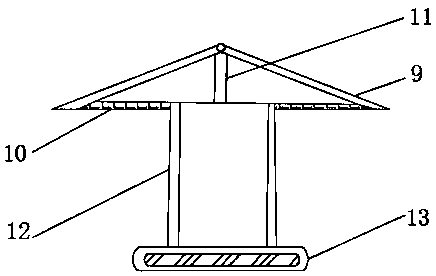

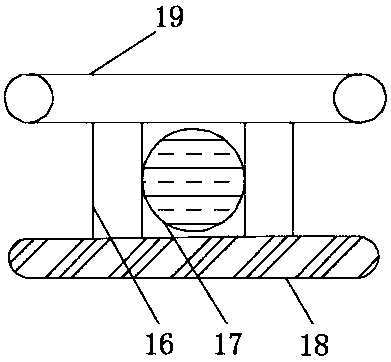

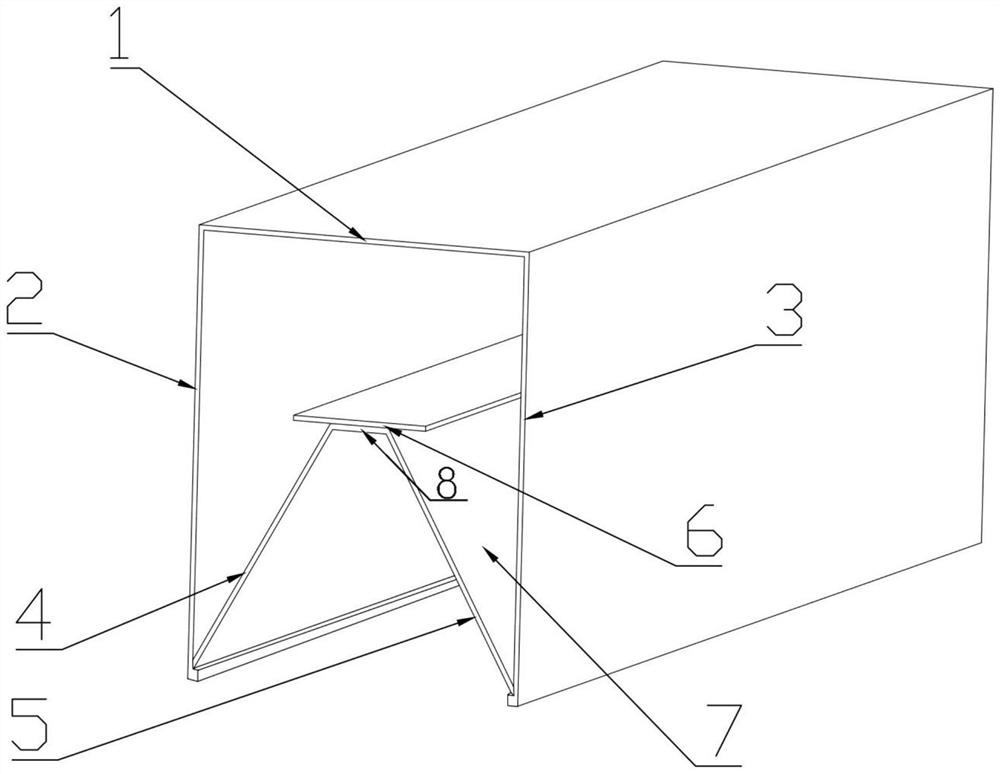

Long and narrow deformation joint of double shear wall and construction method

ActiveCN110984562AImprove lower support strengthPrevent fallingWallsForms/shuttering/falseworksArchitectural engineeringEconomic benefits

The invention relates to a long and narrow deformation joint of a double shear wall and a construction method. The long and narrow deformation joint structurally and mainly comprises an inner side formwork, an outer side formwork, a back ridge, a frame support, an oval steel pipe, a split screw and a shelving platform plate. The construction method mainly comprises the construction steps of formwork manufacturing and splicing, shelving platform mounting, inner side formwork and frame support mounting, steel bar binding mounting, outer side formwork mounting, oval steel pipe mounting, wall concrete pouring, oval steel pipe dismounting, formwork and reinforcing component dismounting, and wall cleaning and maintaining. According to the provided easy-dismounting type inner formwork of the longand narrow deformation joint of the double shear wall and the construction method, the technical problem that in formwork construction of the long and narrow deformation joint of the double shear wall, formwork dismounting is difficult can be solved, the structural characteristics of the oval steel pipe are utilized, a specially-made oval steel pipe rotary jacking formwork dismounting device is adopted, a multifunctional hoisting device for cleaning and maintaining the inner wall face of the deformation joint is adopted, the formworks and operation tools are optimized, construction operationis convenient, fast and efficient, and remarkable technical and economic benefits are achieved.

Owner:核工业西南建设集团有限公司

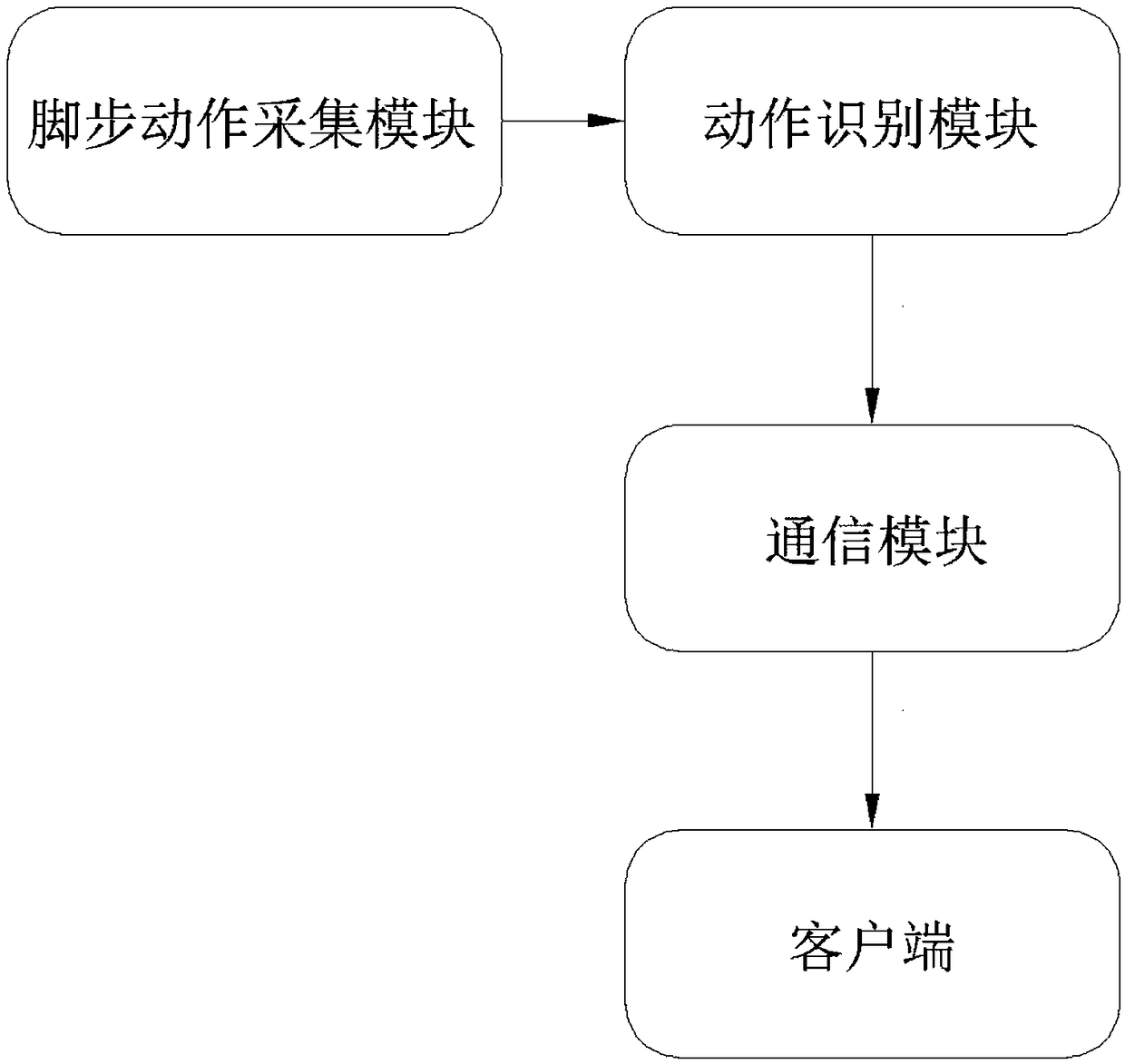

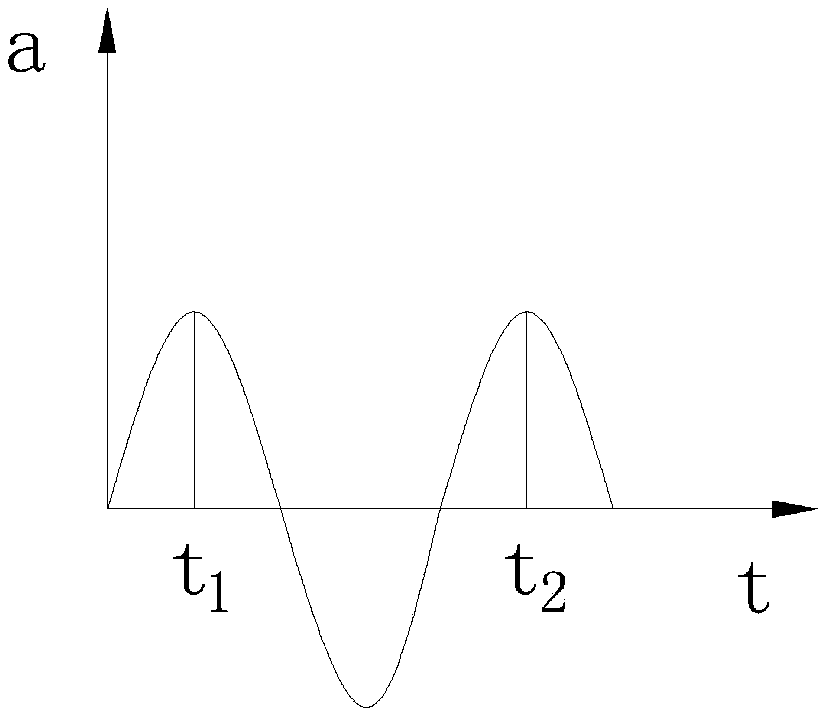

Virtual reality system for human body walking posture control

InactiveCN108762498AImprove experienceImprove realismInput/output for user-computer interactionGraph readingHuman bodyAttitude control

The present invention discloses a virtual reality system for human body walking posture control, and belongs to the technical field of virtual reality devices. The system comprises a wearable device.The instep part of the wearable device is integrated with a step action acquisition module and an action recognition module; and the action acquisition module is connected with the action recognitionmodule, the action recognition module is connected with a communication module, and the communication module is connected with a client. According to the system disclosed by the present invention, whether the user is performing the walking action can be determined by detecting the action of the user leg, in this way, the video playback or pause in the virtual reality application is controlled, andthe interaction effect is natural, so that the realism and immersion of the virtual system are enhanced, the user experience is improved, and the symptoms of vertigo can be greatly reduced.

Owner:重庆子元科技有限公司

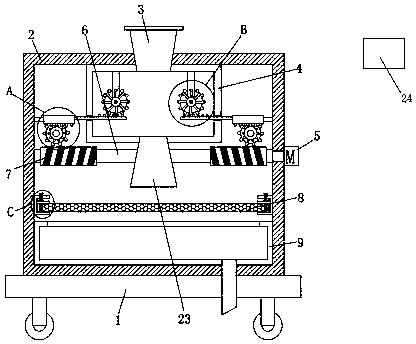

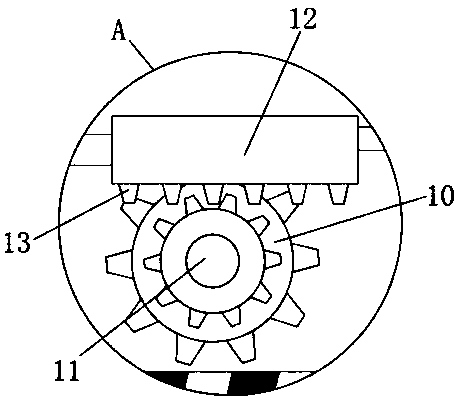

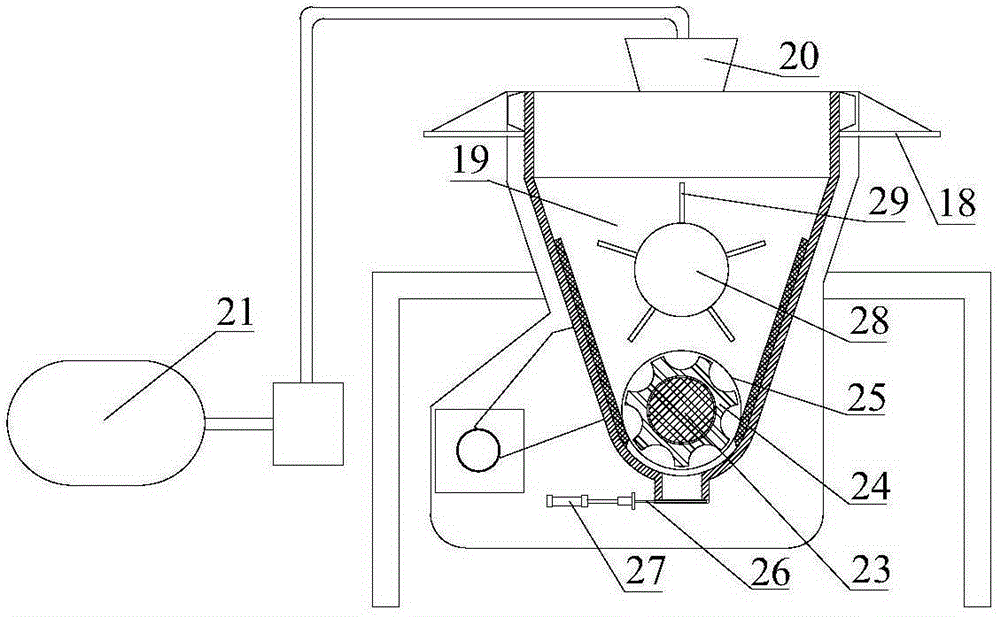

Domestic sewage treatment system used for ships

InactiveCN108467138AEasy to handleWell mixedTreatment involving filtrationMultistage water/sewage treatmentSewageEngineering

The invention discloses a domestic sewage treatment system used for ships. The system comprises a base, the upper side of the base is fixedly connected with a mounting cover, the inner top of the mounting cover is fixedly connected with a purifying cover, the top of the purifying cover is connected with a feeding hopper, and the lower end of the feeding hopper sequentially penetrates through the tops of the mounting cover and purifying cover and extends into the purifying cover. Through arrangement of a servo motor, the servo motor rotates to drive a rotating rod and worms to rotate. The wormsrotate to drive worm wheels to rotate, the worm wheels rotate to drive first gears to rotate, the first gears rotate to drive first racks to move, the first racks move to drive sleeve rods to move, the sleeve rods move to drive connecting rods to move, the connecting rods move to drive second racks to move, the second racks move to drive second gears to rotate, the second gears rotate to drive rings and stirring blades to rotate so that impurities in sewage can be more fully mixed with a flocculant, and therefore the sewage treatment effect is good.

Owner:JIANGSU MARITIME INST

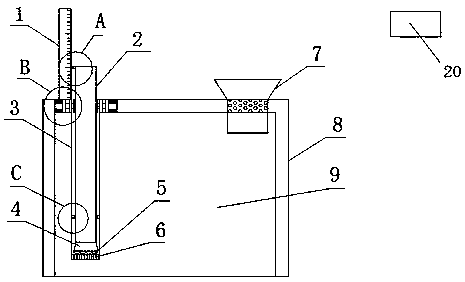

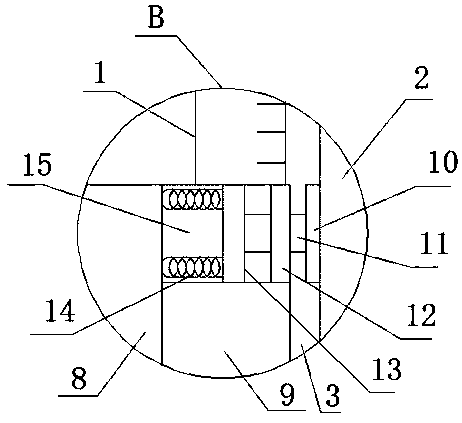

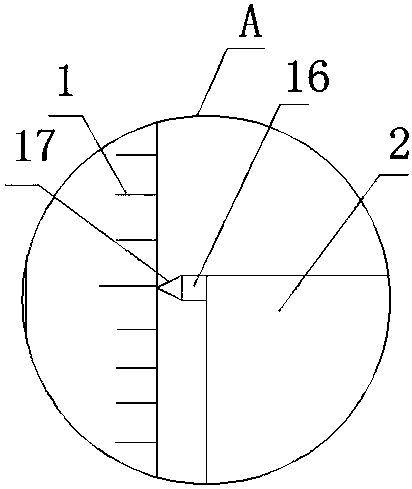

Diesel engine monitoring instrument

InactiveCN108534861AEasy to observeEasy to operateMachines/enginesLevel indicatorsFuel tankDiesel engine

The invention discloses a diesel engine monitoring instrument which comprises a box. The upper end of the box is fixedly connected with an oil inlet device and a measuring device, an oil cavity is formed in the box, the upper side wall of the oil cavity is fixedly connected with a diesel pipe, the bottom end of the diesel pipe is fixedly connected with a filtering device, and the upper end of thediesel pipe penetrates the upper end of the box and is communicated with the outside of the box. When a worker needs to use a diesel engine for operation, the upper end of an oil tank is observed, a pointer on a vernier corresponds to readings on a scale plate, the worker decides whether to add oil or not after knowing the quantity of oil in the oil tank, the oil is poured into the oil tank from an oil inlet if oiling is needed, a floating block can drive the pointer on the vernier to slide upwards on the scale plate until an appropriate amount of oil is added, the monitoring instrument is convenient to observe and simple to operate, convenience is brought for agricultural production, and production efficiency is improved.

Owner:JIANGSU MARITIME INST

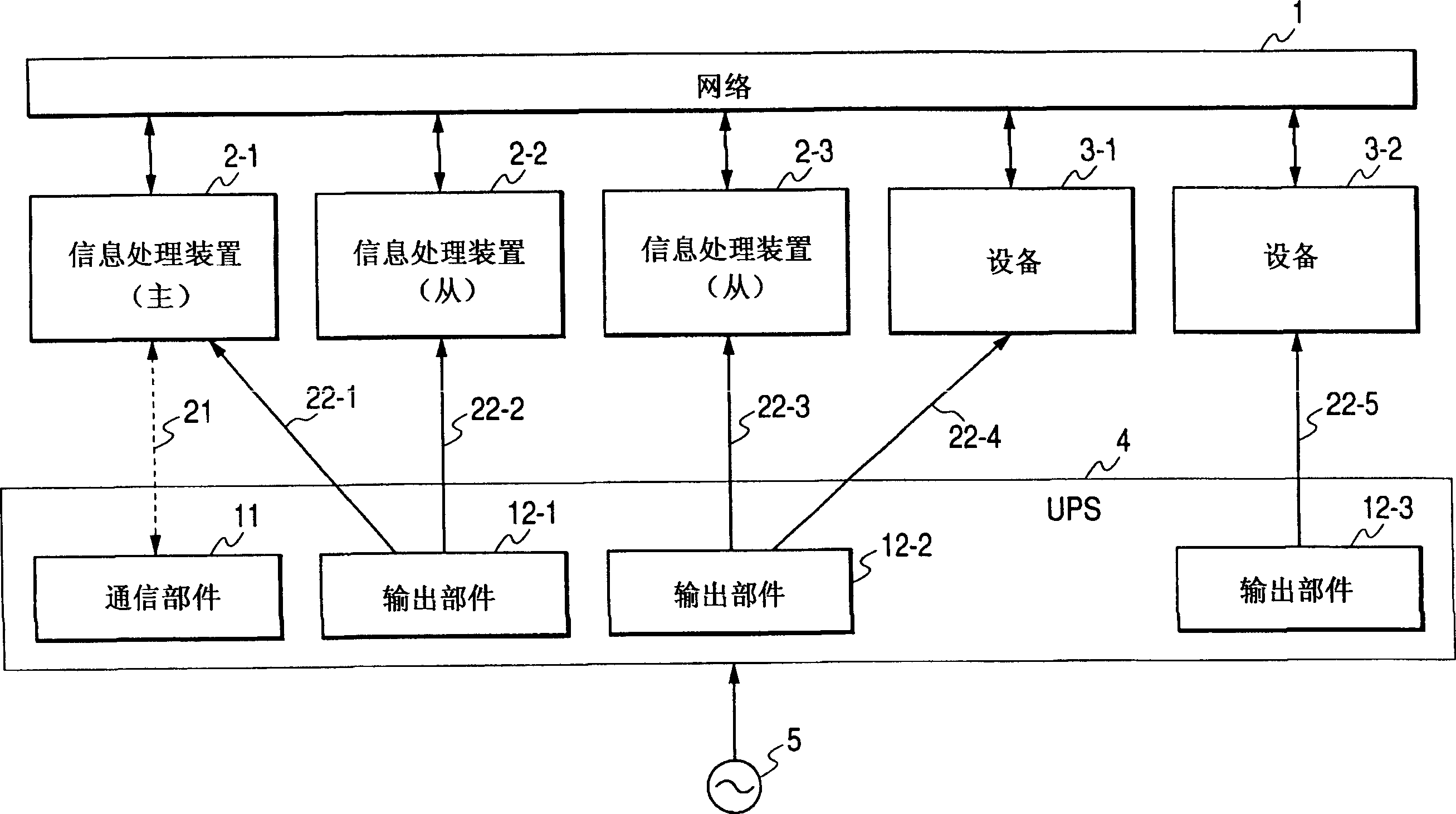

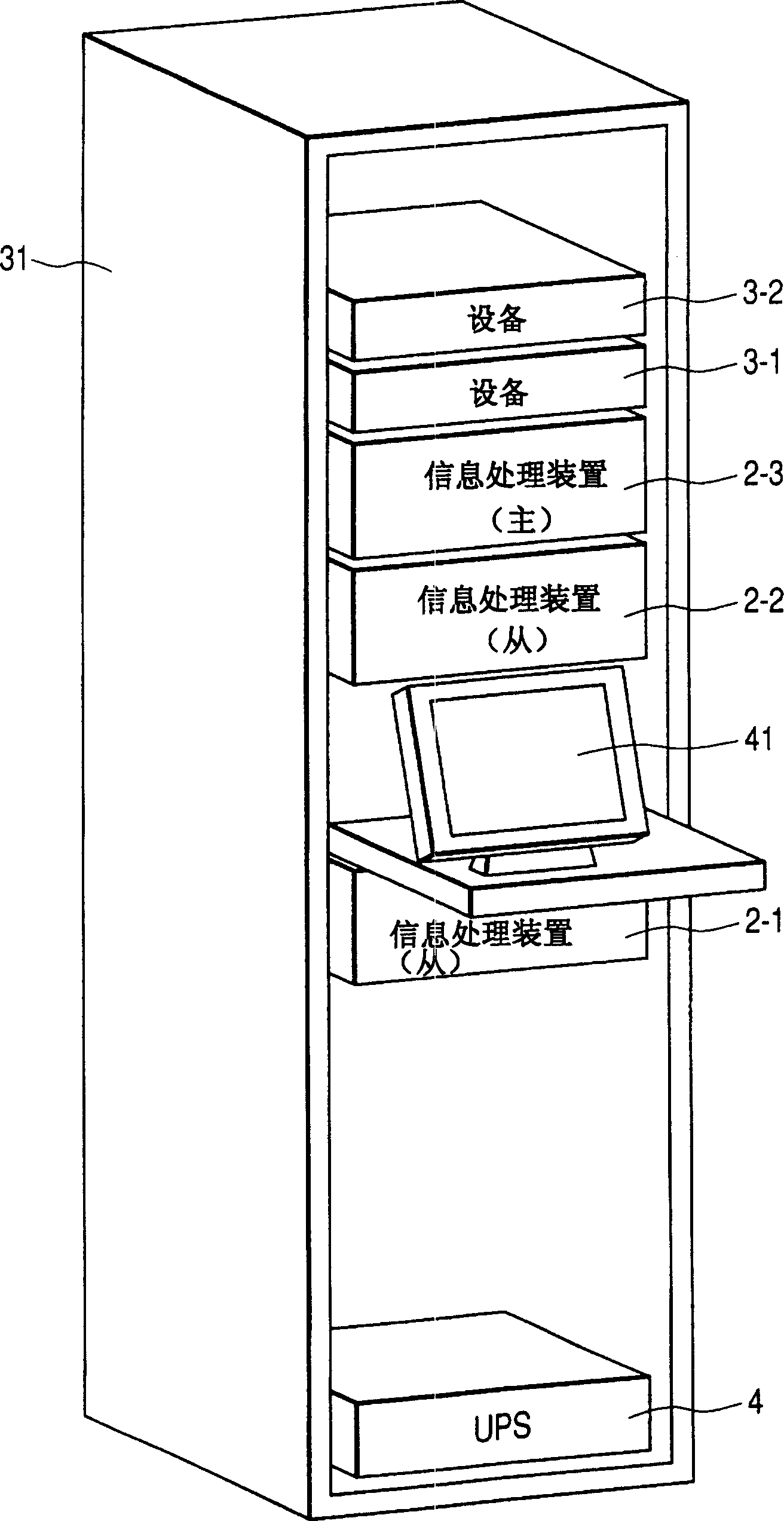

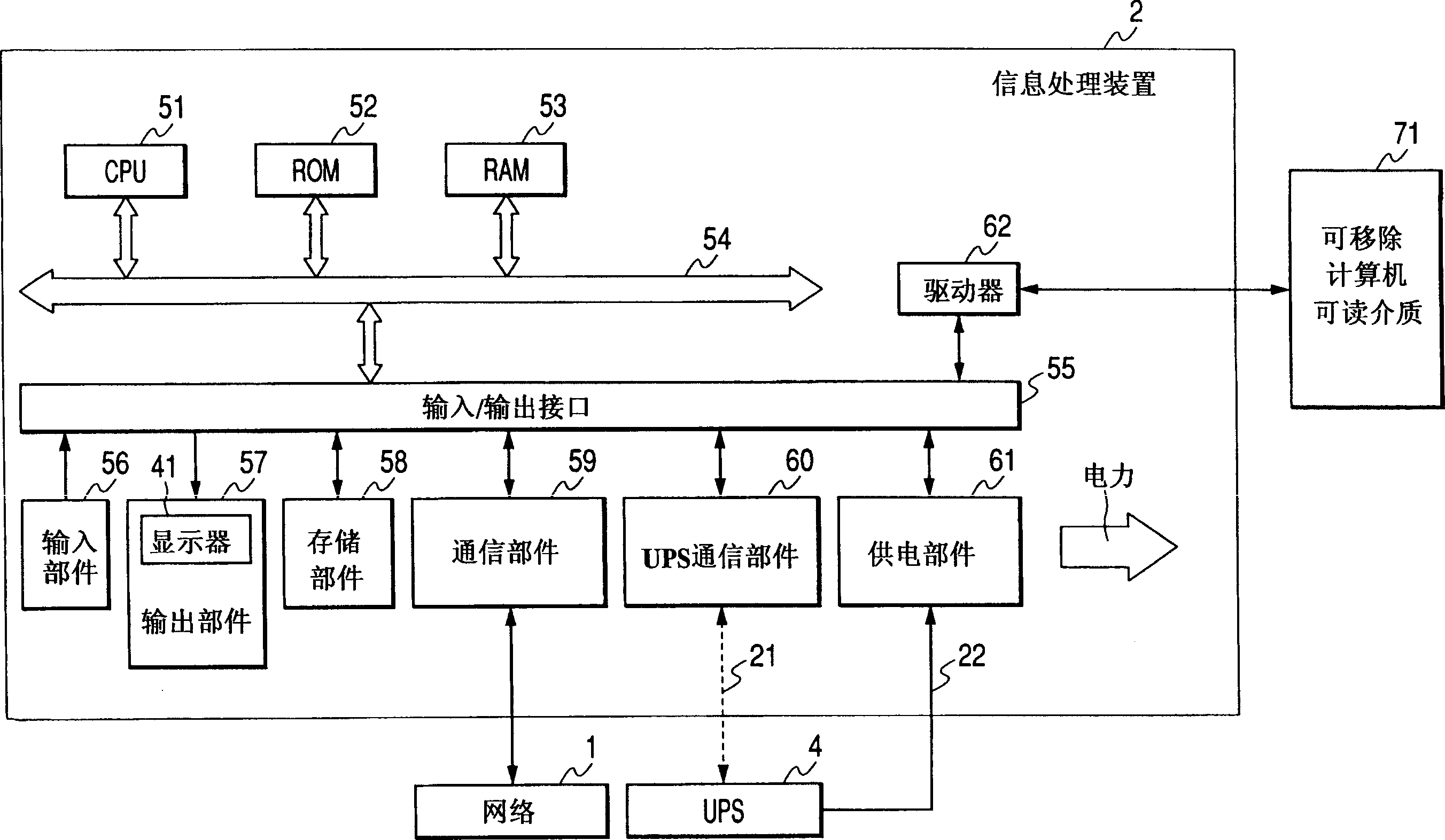

Information processing apparatus and method, and computer-readable medium

InactiveCN1584786AControl statusStates do not need to be individually controlledVolume/mass flow measurementPower supply for data processingInformation processingEngineering

A UPS monitoring part monitors a state of a UPS, on the basis of an information which was transmitted from the UPS which was connected to an information processing apparatus, and received by a UPS communication part. A UPS control part, on the basis of a result of that monitoring, generates a control information for individually controlling respective states of a plurality of electric power output parts of the UPS, in accordance with a condition of power-off of each load which was connected to the corresponding electric power output part, and carries out a control for transmitting it from the UPS communication part to the UPS.

Owner:ORMON CORP

Weaving technique for multicolor layer-collection high-grade flax knitting fabric

The invention relates to a weaving technique of a multi-color set layer top grade flax fabric, in which, a cylindrical pure flax top grade fabric is woven by stocking, yarn cleaning and in turn arrangement which is called double-warp feed, and the jacquard control procedure of a computer circular knitting machine is adopted; a hot setting machine is adopted to carry out high temperature setting; the flax fabric after set is reasonably cut according to a preset dimension to become a qualified semi-finished product; a lace prepared in ahead is whipstitched on the flax fabric with a regulated dimension specification to manufacture into a finished product. The pure flax top grade fabric of the invention is manufactured by selecting the flax with excellent quality, can be repeatedly washed and flung by a machine, is free from ironing, has an exquisite appearance and has no drapes.

Owner:张俊杰

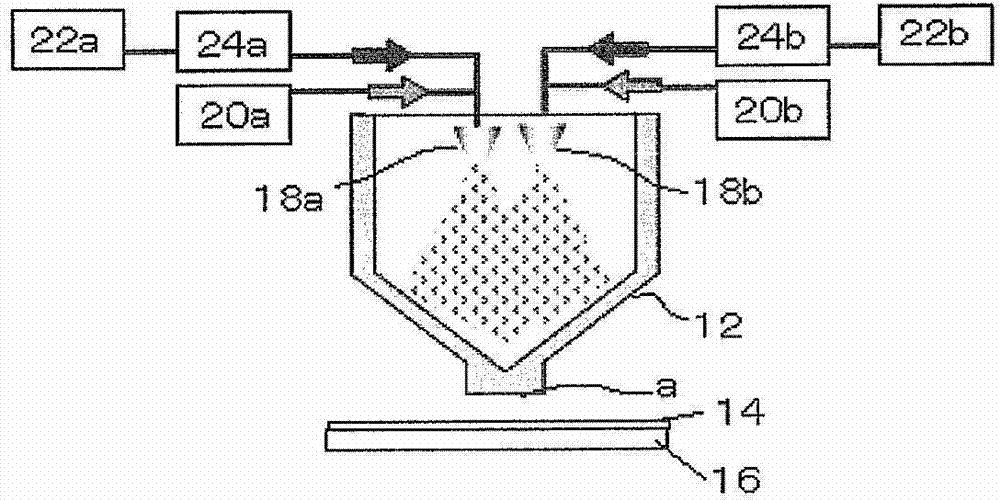

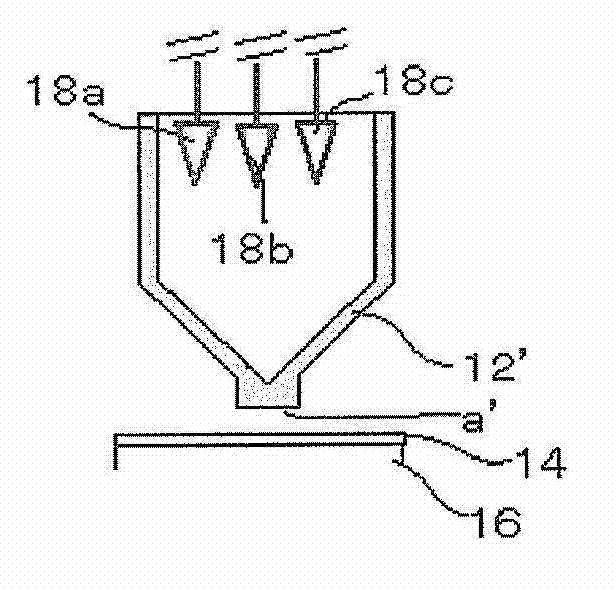

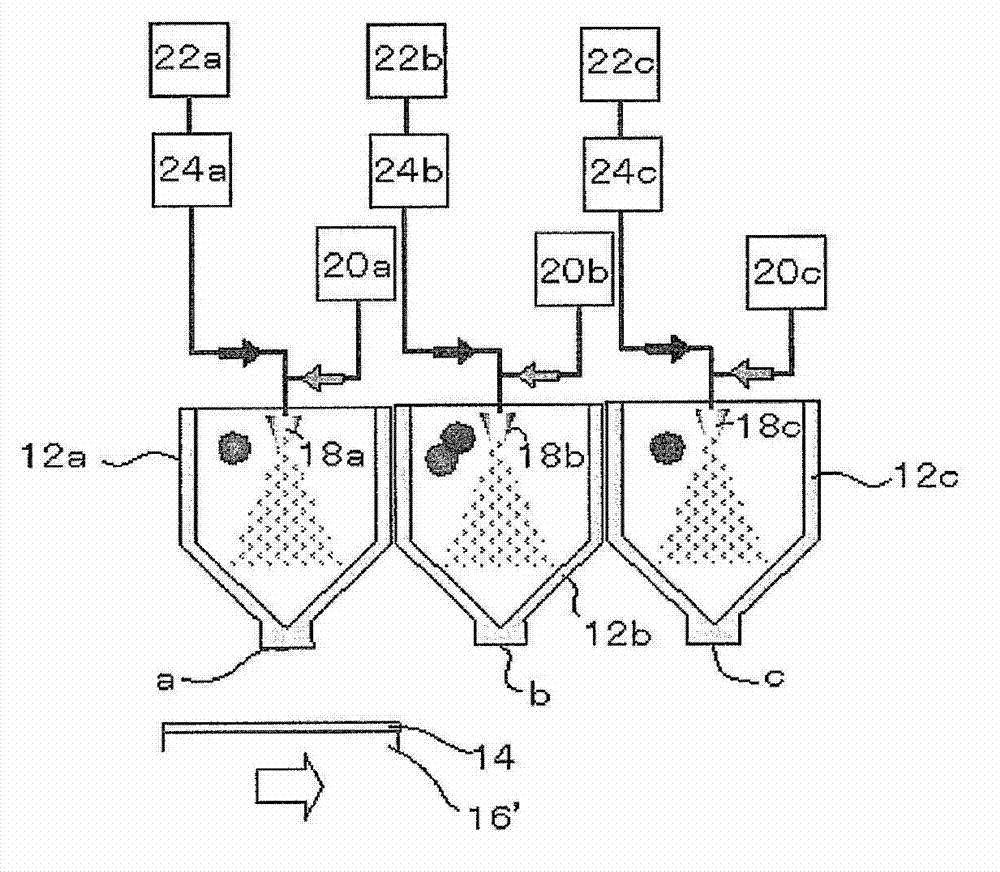

Thin film manufacturing method and manufacturing device

InactiveCN102892516AControl statusEasing production methodLiquid surface applicatorsElectroluminescent light sourcesOptoelectronicsBarrier effect

Provided is a method for manufacturing a multilayer thin film whereby energy barrier effects due to the interface between each layer are mitigated. The method for manufacturing the thin film includes: a bottom layer forming step for forming a bottom layer containing a solute A, wherein, (1) droplets are formed by spraying a raw liquid formed by dissolving and / or dispersing a solute in a solvent, (2) the solvent in the droplets is volatilized and condensed, and (3) a thin film is formed by depositing the condensed droplets on a substrate or on a thin film disposed on a substrate, performed in that order; a top layer forming step for forming a top layer containing a solute B on the bottom layer, wherein the abovementioned steps (1) to (3) are performed sequentially; and a mixed layer forming step for forming a mixed layer containing the solutes A and B, wherein the abovementioned steps (1) to (3) are performed sequentially between the bottom layer forming step and the top layer forming step.

Owner:FUJIFILM CORP

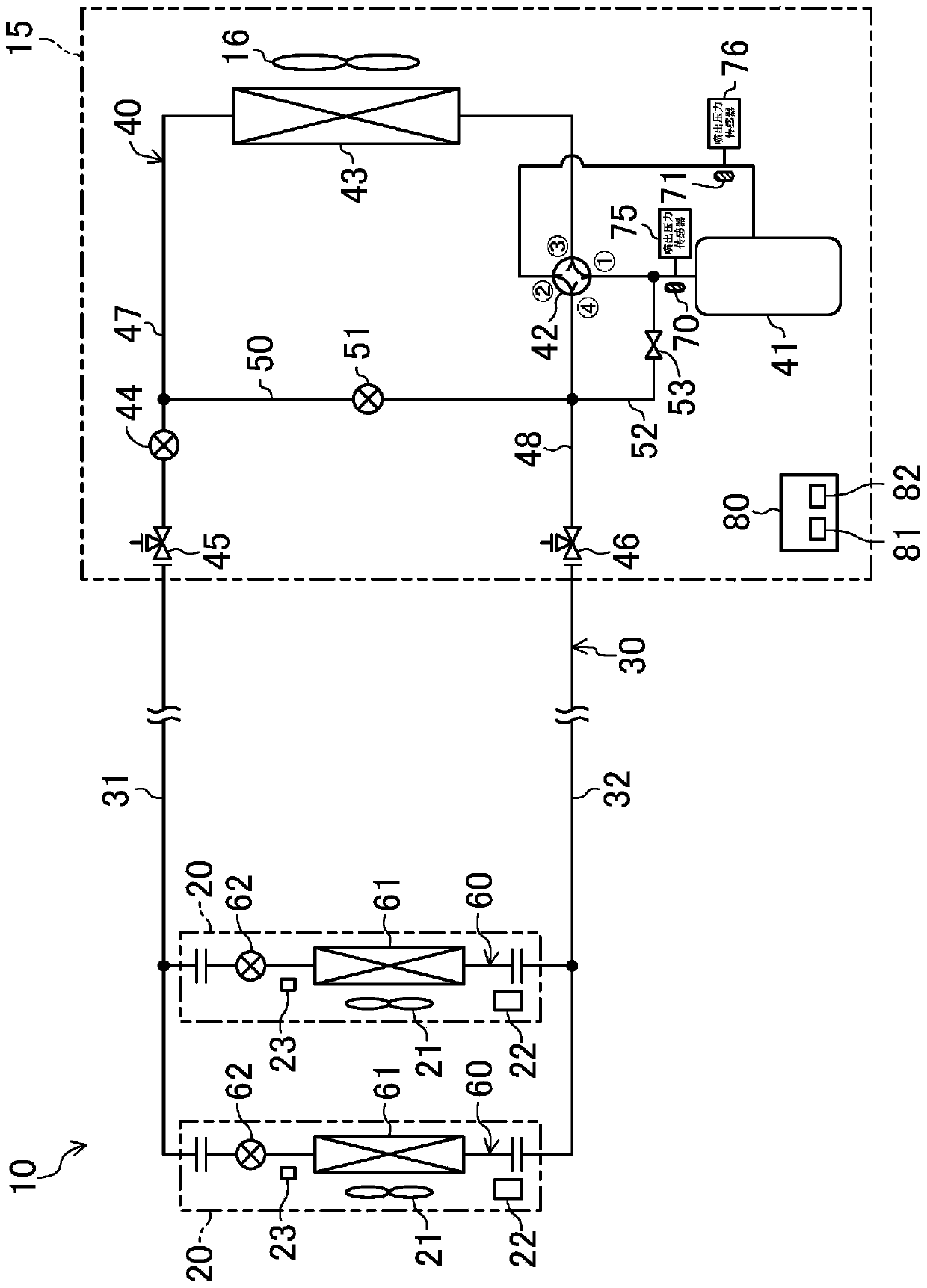

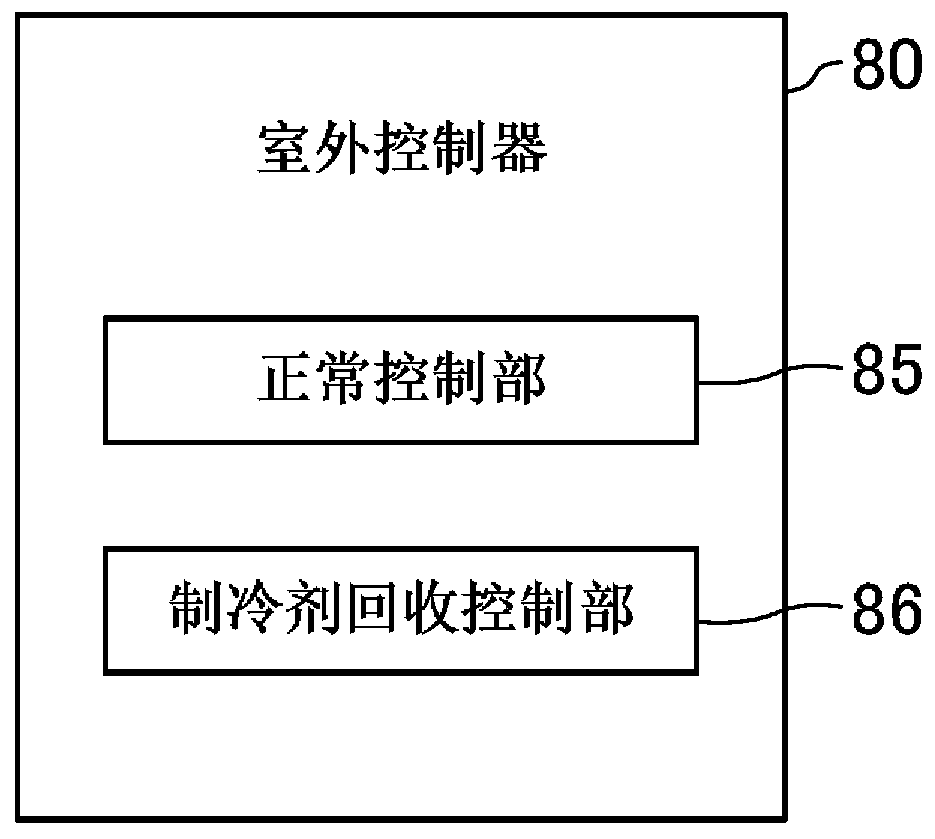

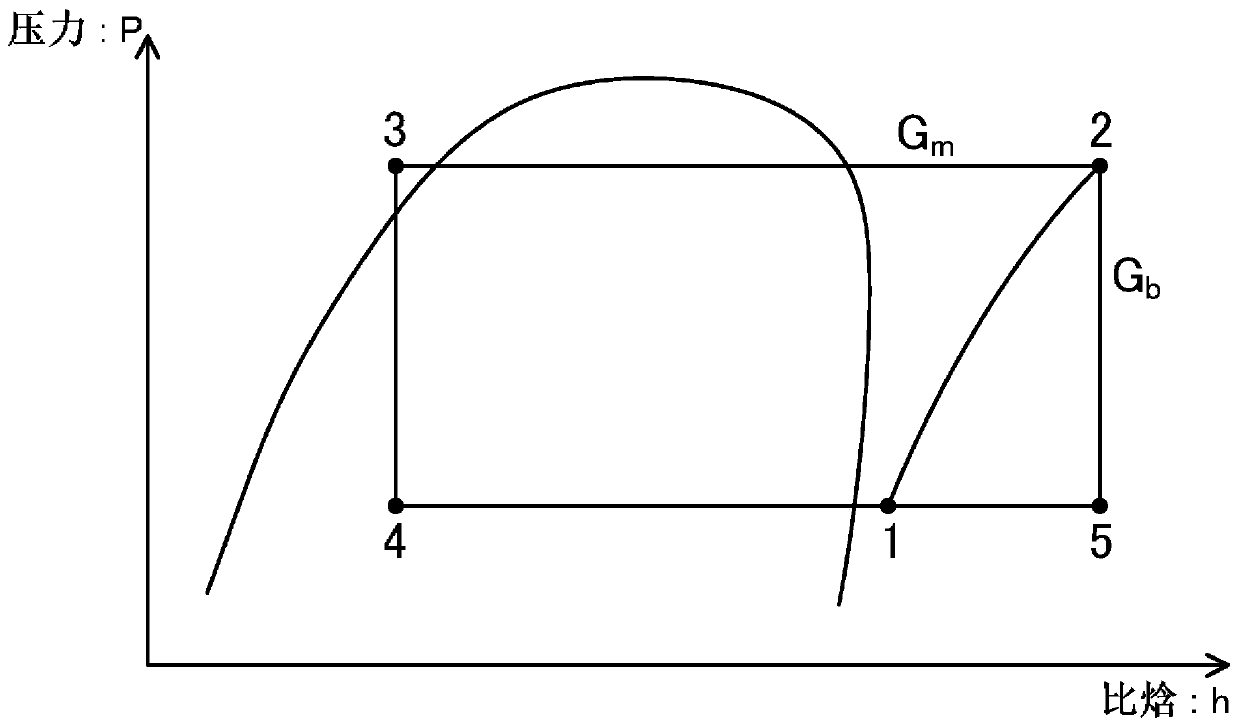

Refrigeration device

ActiveCN111201411AEjection temperature riseExcessive rise in ejection temperatureMechanical apparatusCompression machines with non-reversible cycleRefrigerant reclamationEngineering

A liquid-side pipe (47) of an outdoor circuit (40) is provided with an outdoor expansion valve (44). Furthermore, the outdoor circuit (40) is provided with a liquid-side bypass pipe (50) for having the liquid-side pipe (47) in communication with the intake side of a compressor (41). When an outdoor controller (80) receives a signal indicating that a refrigerant has leaked from an indoor circuit (60), the outdoor controller performs refrigerant recovery control operations for operating the compressor (41) in a state wherein the liquid-side control valve (44) is closed, and also performs, in therefrigerant recovery control operations, valve control operations for opening a liquid-side bypass valve (51) of the liquid-side bypass pipe (50). As a result, the refrigerant can be recovered from ause-side circuit to a heat source-side circuit, while preventing the compressor from being damaged, and the leakage amount of the refrigerant from the use-side circuit can be reduced.

Owner:DAIKIN IND LTD

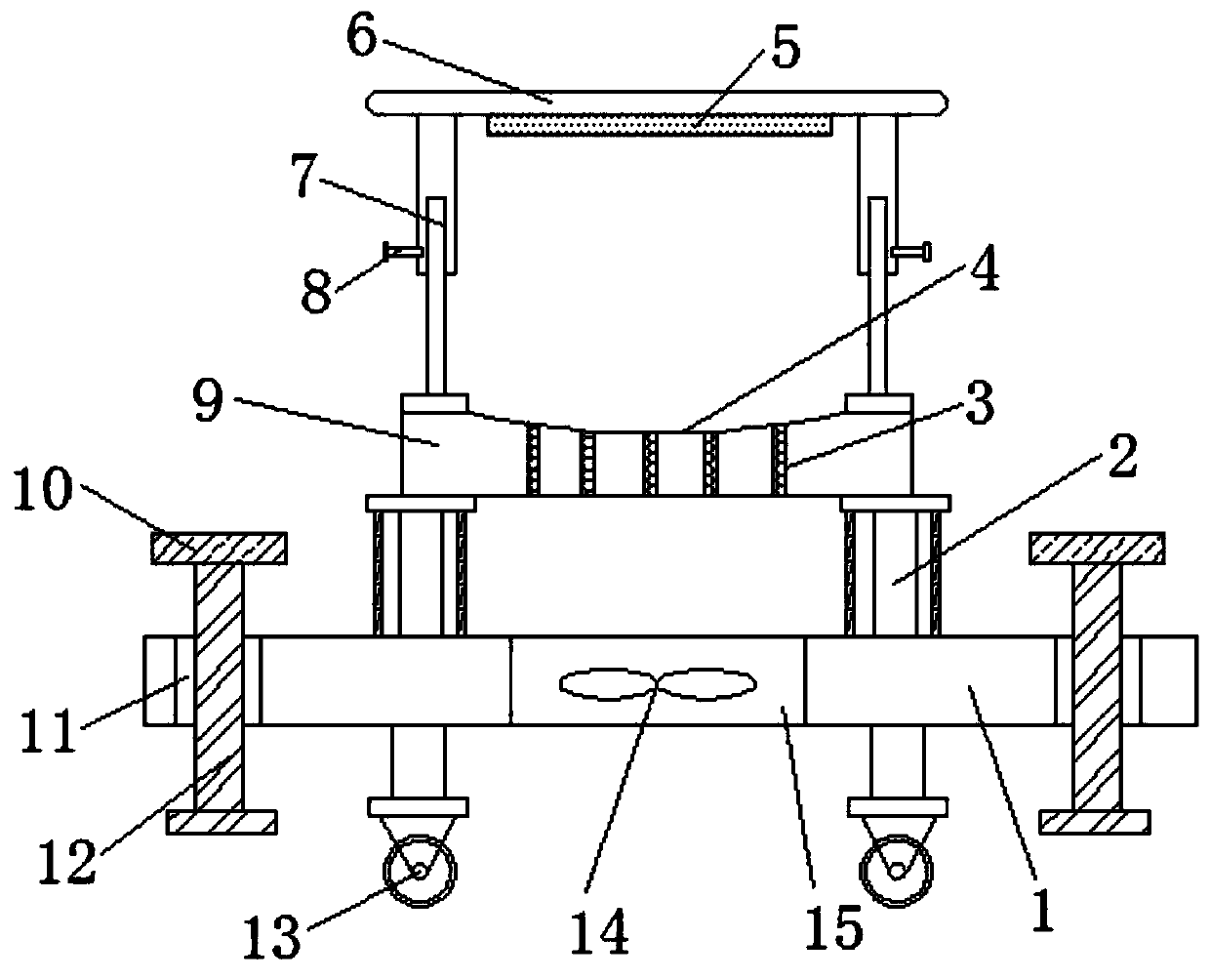

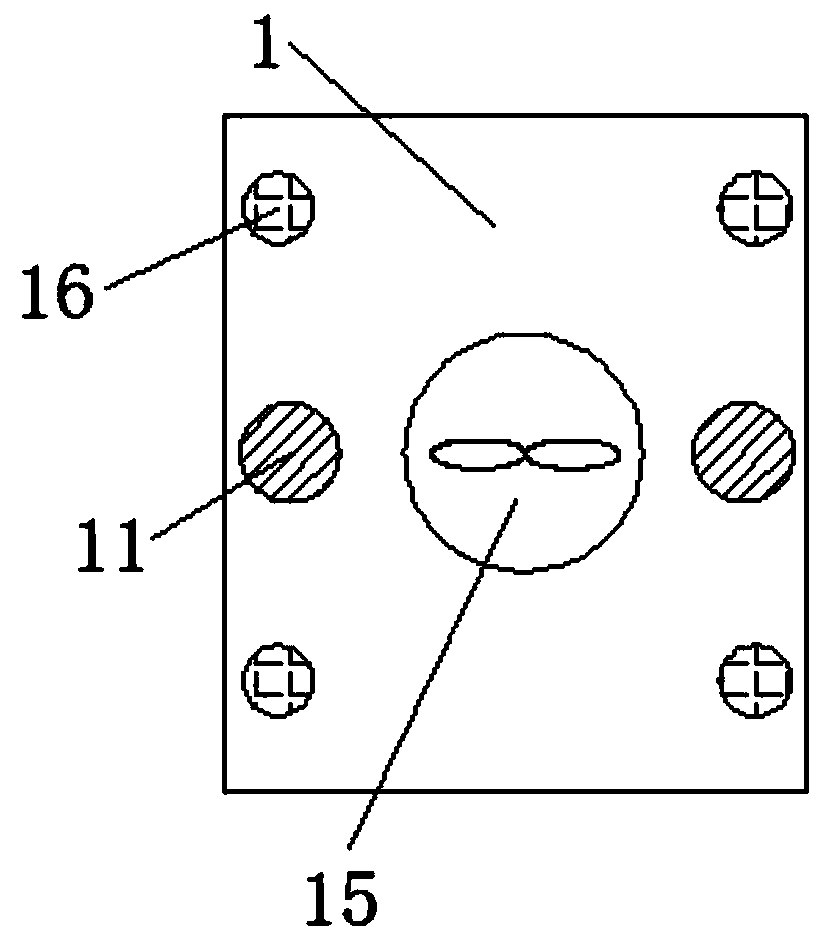

Damping base for motor

PendingCN110829698AEasy to fixImprove cooling effectCooling/ventillation arrangementSupports/enclosures/casingsElectric machineMechanical engineering

The invention discloses a damping base for a motor. The damping base comprises a base, wherein a supporting plate is fixedly connected with an upper portion of the base through a damping device, a through hole is formed in the middle of a surface of the base, a cooling fan is embedded in the through hole, universal wheels are welded to a bottom end of the base, a supporting leg is in spiral connection with the surface of the base, a top end of the supporting leg is welded with a handle, the damping device comprises a top plate, a connecting rod, a spring, a sleeve and a bottom plate, heat dissipation holes are formed on a surface of the supporting plate, an upper surface of the supporting plate is an arc surface, pressing plates are welded to two sides of the supporting plate through telescopic rods, and rubber pads are bonded to bottom ends of the pressing plates. The damping base is advantaged the damping base is novel in design, simple in structure, convenient to operate, good in using effect, wide in applicability, capable of conveniently fixing and installing the motor, good in stability, capable of effectively relieving vibration, more environmentally friendly, convenient tomove, capable of conveniently dissipating heat of the motor, capable of avoiding heat accumulation, capable of improving the using safety and capable of prolonging the service life.

Owner:TIANJIN CHENBAO ELECTROMECHANICAL TECH CO LTD

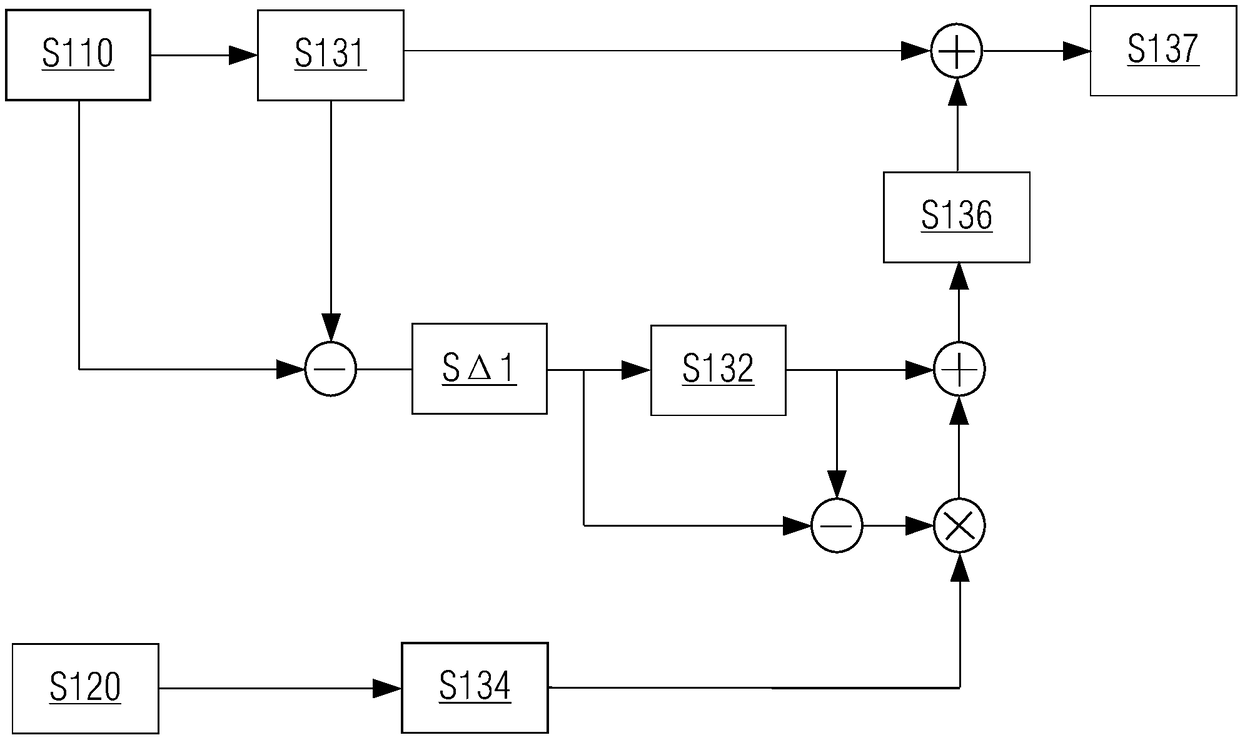

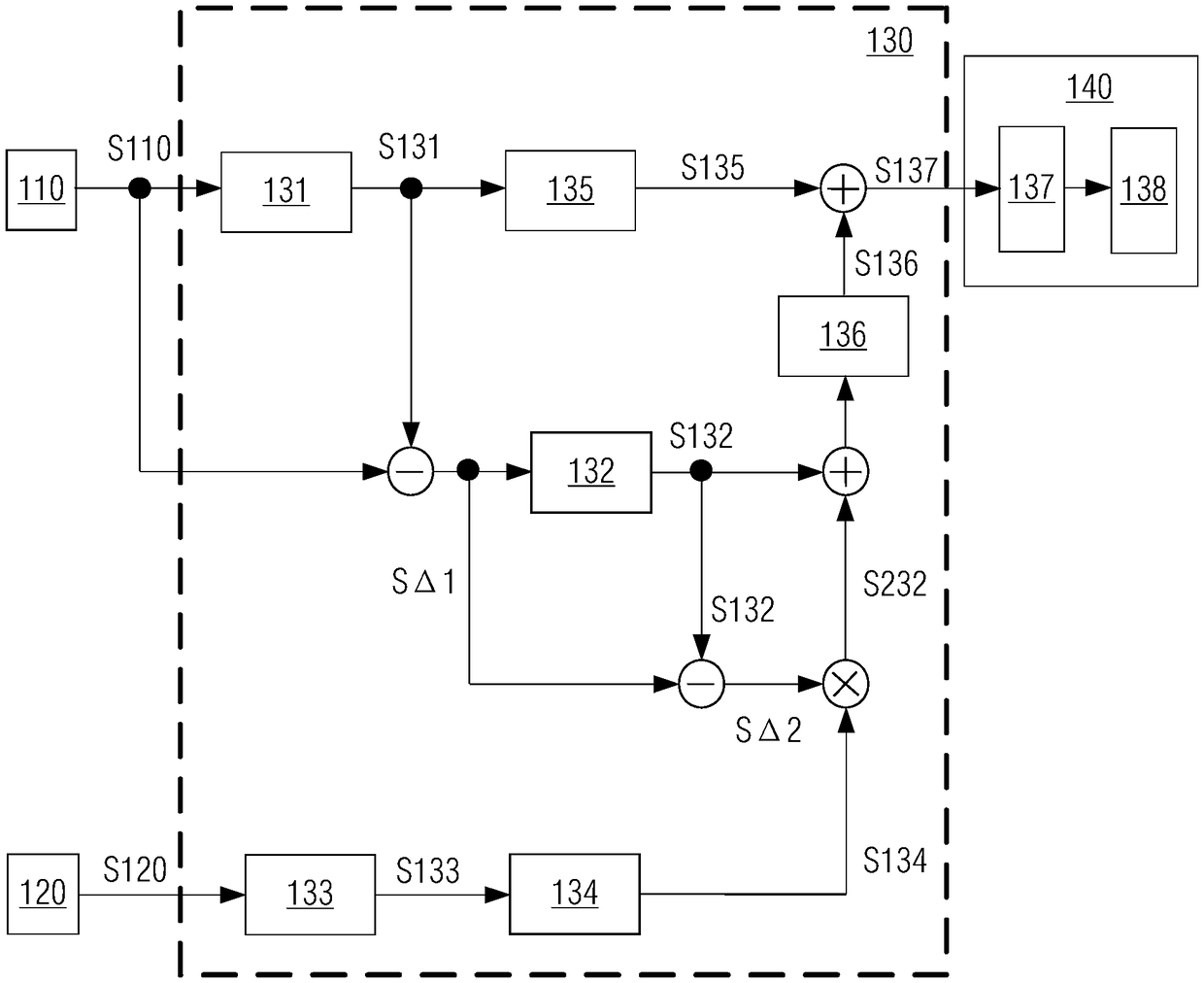

Machining method for controlling fixed length cutting of workpiece by tool, cutting device and machine tool

ActiveCN109164755APrecise and flexible position controlPrecise and flexible state controlProgramme controlComputer controlControl signalState parameter

The invention relates to a machining method for controlling fixed length cutting of a workpiece by a tool, a cutting device and a machine tool. The machining method comprises the steps of: detecting the position of the workpiece to obtain a position measurement signal; detecting inertial filtering on the position measurement signal by a cutting state parameter of the tool to obtain a first filtervalue; obtaining a second filter value from the position measurement signal and the first filter value; calculating a control compensation value from a first filter error, the second filter value andthe cutting state parameter; and introducing the first filter value and the control compensation value into a virtual spindle model of the tool to calculate a control signal for the cutting process. The method solves the technical problem that the cutting position is difficult to meet the relevant requirements by simply using the inertial filtering to process the position signal of the workpiece during the cutting process. By compensating the filter position, the speed of the cutting tool at the non-cutting point is smooth and the vibration is small, so that the cutting accuracy at the shear point is improved, and the quality of the machined workpiece is significantly improved.

Owner:SIEMENS FACTORY AUTOMATION ENG

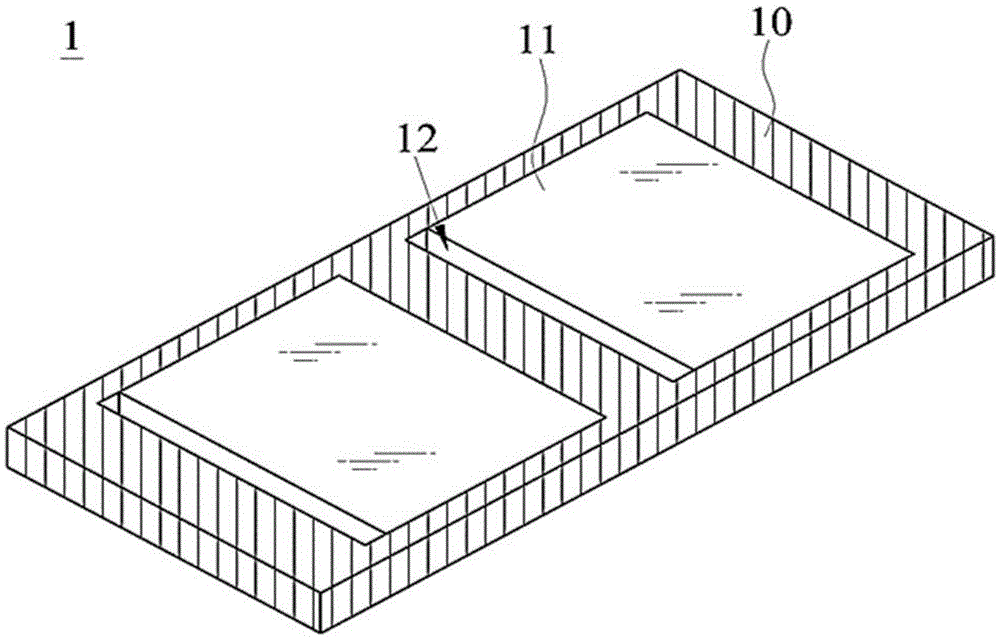

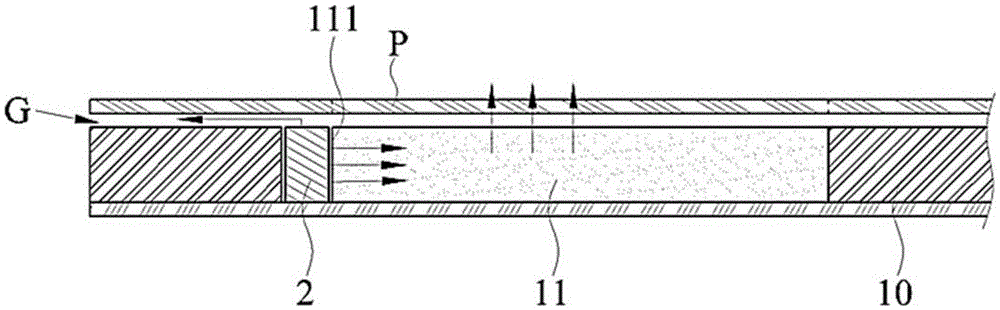

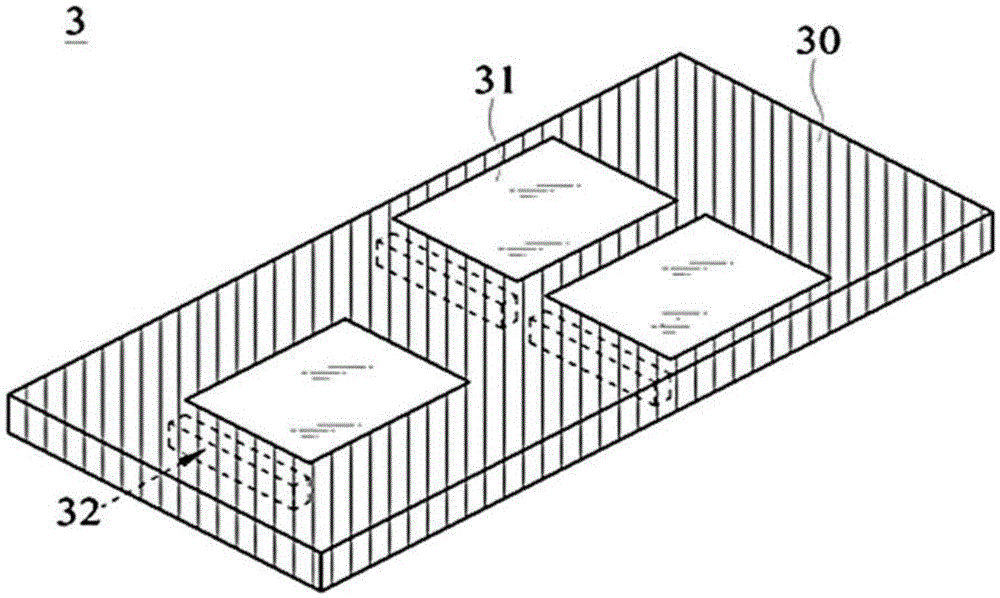

Light guide plate with regional light outlet and manufacturing method thereof

The invention provides a light guide plate with regional light outlet and a manufacturing method thereof. The light guide plate comprises a shading element and a transmittance element, the transmittance element is connected with the shading element in the manner of integral forming, a blind hole for embedding a light source is formed between the shading element and the transmittance element so that the light of the light source can be blocked by the shading element, and only the lateral light is employed so that light outlet is formed at the transmittance element. Therefore, the shading element can block the light which is not incident to the transmittance element, the light is prevented from forming light outlet in a non-transmittance-element area of the light guide plate, and the phenomenon of light leakage is prevented. When the light guide plate is employed to be matched with a display panel, merely the area with specific patterns can be displayed, and adjacent patterns which are not in the display state are not simultaneously lightened.

Owner:SHANGHAI XIANGLONG ELECTRONICS TECH

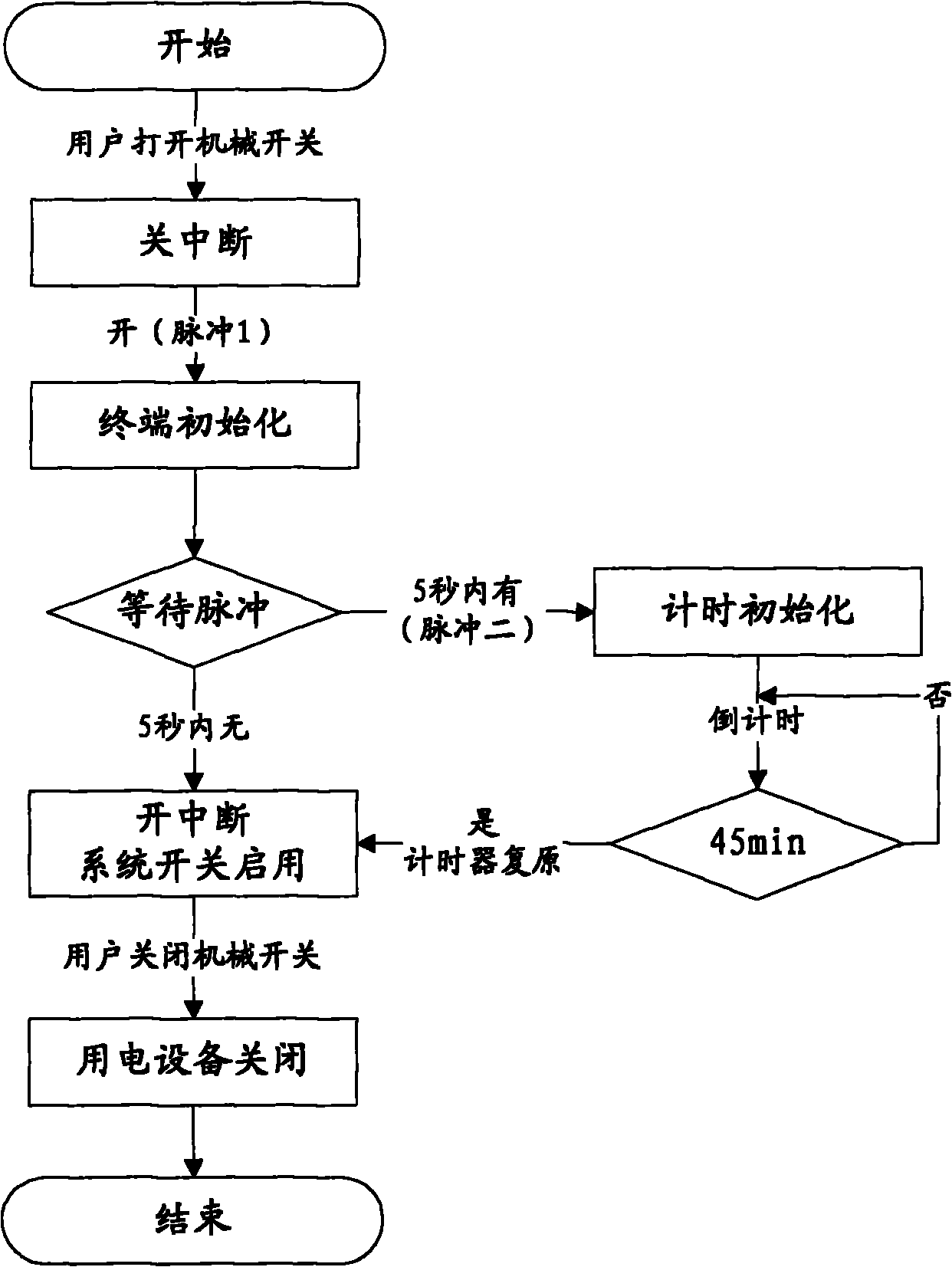

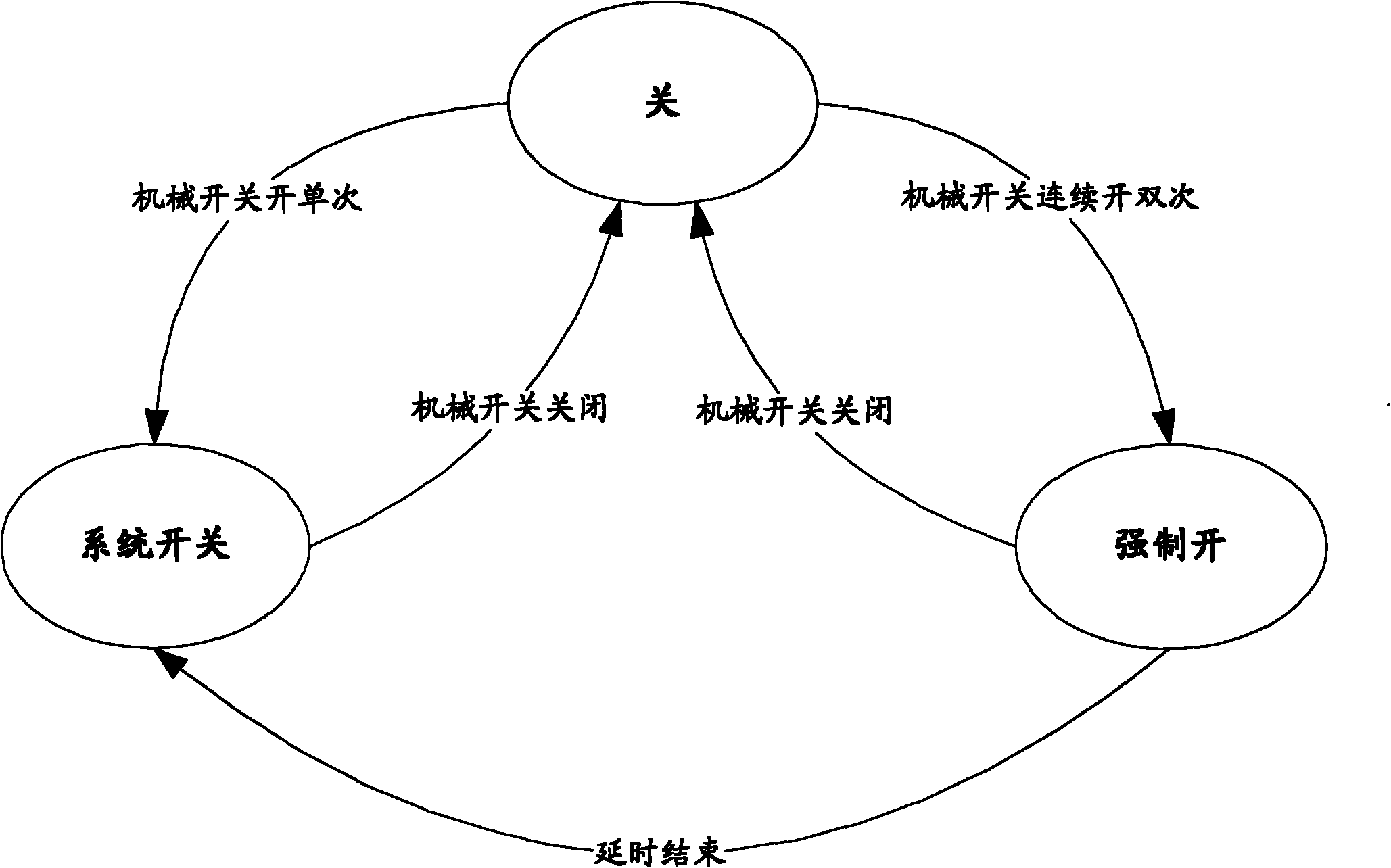

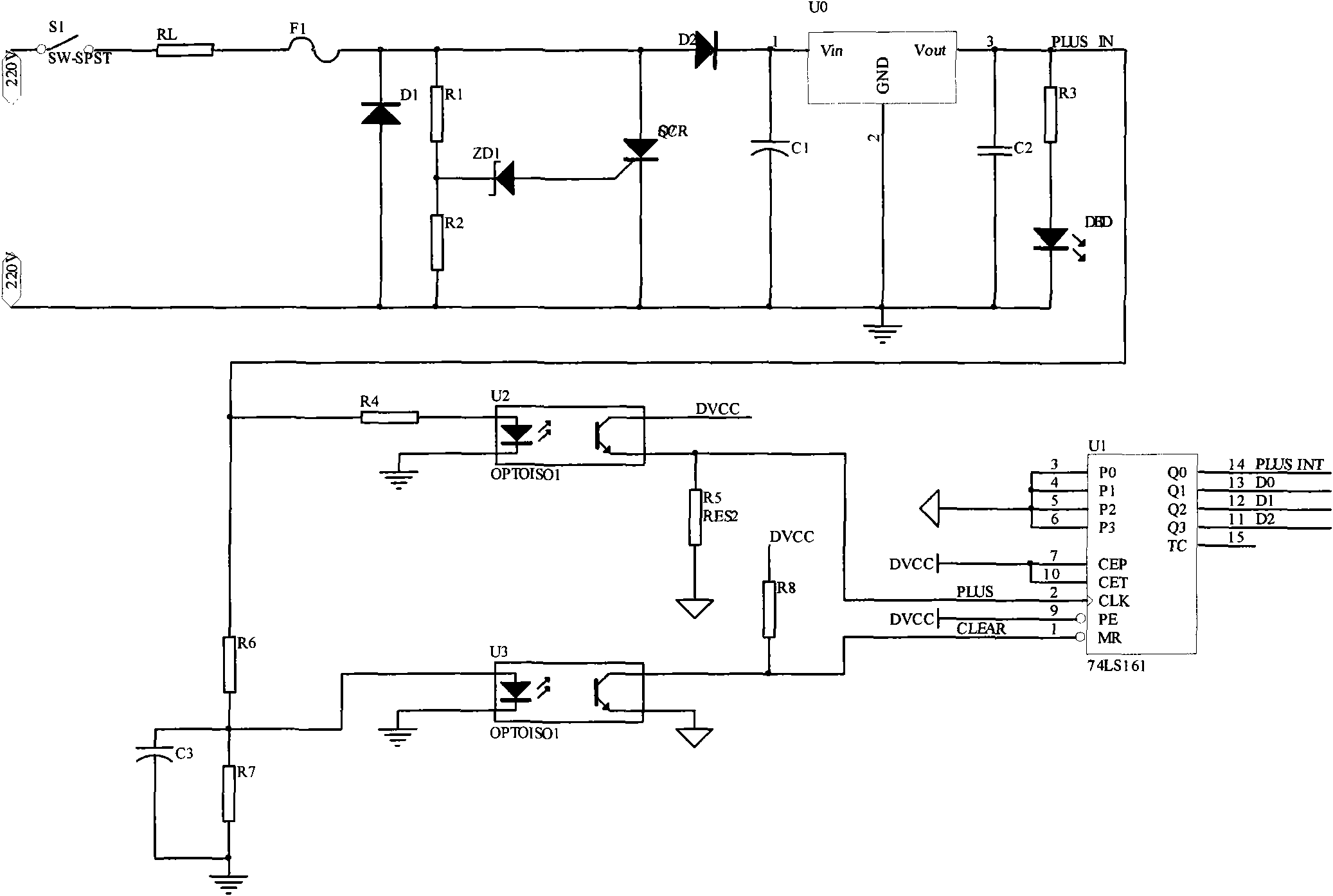

Intelligent power switch terminal and control method thereof

InactiveCN101834589AControl statusNo change in arrangementElectronic switchingPower switchingEngineering

The invention discloses an intelligent power switch terminal and a control method thereof. The switch terminal comprises a mode regulating unit which is used of regulating a mode in which the switch terminal is according to the operation of a user; when sensing the continuous starting action of the switch terminal within set time, the mode regulating unit is used for automatically switching an electrical equipment using state corresponding to the switch terminal into a forced starting state, starting the timing and keeping the starting state within set time; when the timing time arrives, the mode regulating unit is used for automatically switching the electrical equipment using state into a system hosting state; and when a user closes a mechanical switch, the mode regulating unit is used for switching the electrical equipment using state into the closing state. The intelligent power switch terminal and the control method thereof more effectively control the electrical equipment using state on the premise of unchanging the original switch function.

Owner:王鑫印

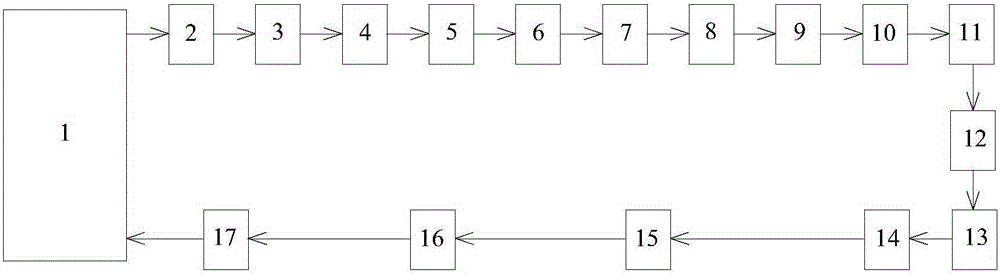

Production systems for concrete elements

ActiveCN104057537BReduce labor intensitySimple structureDischarging arrangementCeramic shaping plantsPre treatmentWaste management

A concrete member production system comprises a formwork table conveying device, formwork table pre-treatment equipment, a first spreader, a second spreader, post-spreading treatment equipment, a maintenance storehouse and an edge-on bottom formwork removal device, wherein a formwork removal station, a formwork pre-treatment station, a first spreading station and a vibro-compacting station are sequentially arranged on the formwork table conveying device and at the exit of the maintenance storehouse; a post-spreading treatment station, a second spreading station and an insulation board placing station are sequentially arranged on the formwork table conveying device and at the entrance of the maintenance storehouse; the edge-on bottom formwork removal device, the formwork table pre-treatment equipment, the first spreader, a formwork vibrating device, the second spreader and the post-spreading treatment equipment are correspondingly arranged on the formwork removal station, the formwork pre-treatment station, the first spreading station, the vibro-compacting station, the second spreading station and the post-spreading treatment station respectively to form a circulating production system. The concrete member production system is operated mechanically, achieves continuous production, saves time and labor and improves the working efficiency.

Owner:HEBEI XUELONG MACHINERY MFG

Diaphragm type hole-variable aerator

InactiveCN102583714AAvoid bugs that are prone to cloggingGuaranteed to passTreatment using aerobic processesSustainable biological treatmentBiochemical engineeringMicrometer

The invention relates to a diaphragm type hole-variable aerator which comprises a tray and an upper cover connected with the tray in a matching way, wherein the upper cover is provided with a synthetic rubber diaphragm with high elasticity, the synthetic rubber diaphragm with high elasticity is provided with a self closing hole with 150 micrometer to 200 micrometer hole diameter, the aerator is arranged on an ABS (Acrylonitrile Butadiene Styrene) air pipe, and the two ends of the ABS air pipe are provided with a level governor. The diaphragm type hole-variable aerator provided by the invention has the advantages of favorable use effect and small daily maintenance quantity, and moreover the diaphragm type hole-variable aerator is provided with the level governor.

Owner:YIXING GLOBAL WATER TREATMENT EQUIP

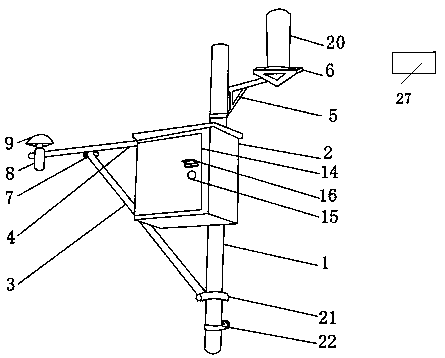

Hydrology and water resource monitoring system

InactiveCN108398122AAvoid damagePrevent openingTransmission systemsOpen water surveyForeign objectWater resources

The invention discloses a hydrology and water resource monitoring system. The system comprises a right cylinder, a monitoring box, a third support and a first fixing ring are movably installed on theouter surface of the right cylinder, the third support is located on the upper portion of the monitoring box, the first fixing ring is located on the lower portion of the monitoring box, a box door ismovably installed on the outer surface of the front end of the monitoring box, a lock block and a baffle are movably installed on the outer surface of the front end of the box door, the baffle is located on the upper portion of the lock block, and a protection pad is movably installed in the baffle. According to the hydrology and water resource monitoring system, a protection cover, the baffle and a second fixing ring are arranged, an ultrasonic level gauge can be effectively protected, the phenomenon that the ultrasonic level gauge is impacted by a foreign object and damaged is prevented, the lock block can be isolated and protected, the phenomenon that the lock block is washed by rainwater and rusts is avoided, a worker can climb the right cylinder conveniently, and a better use prospect is brought.

Owner:JIANGSU MARITIME INST

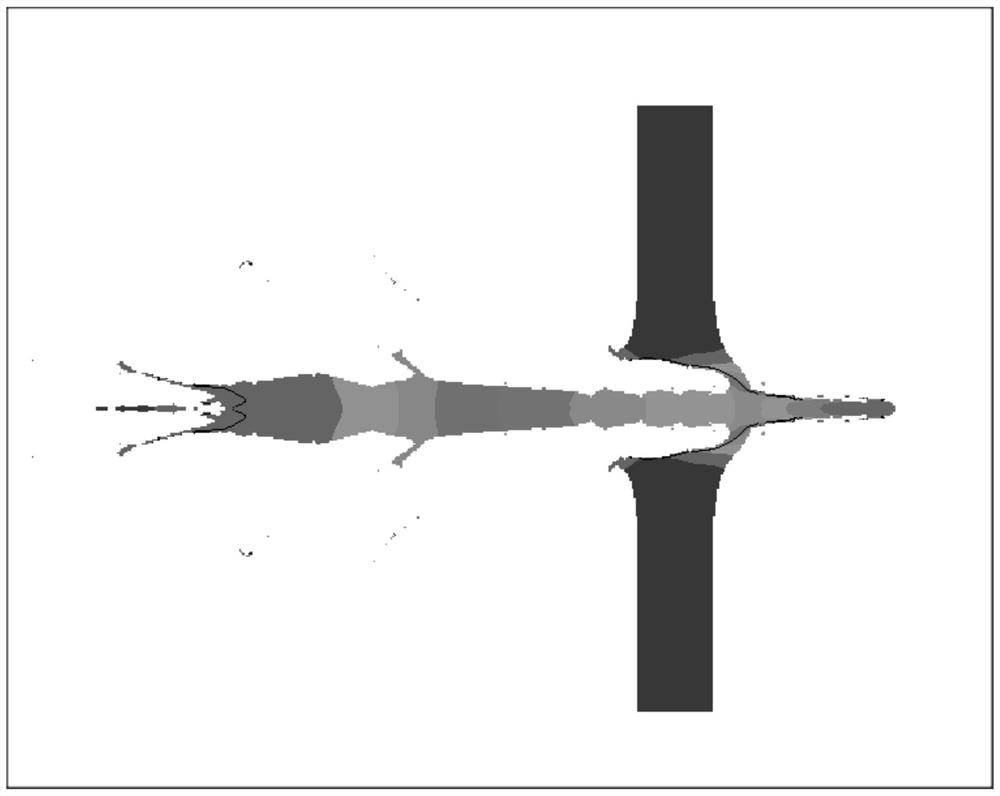

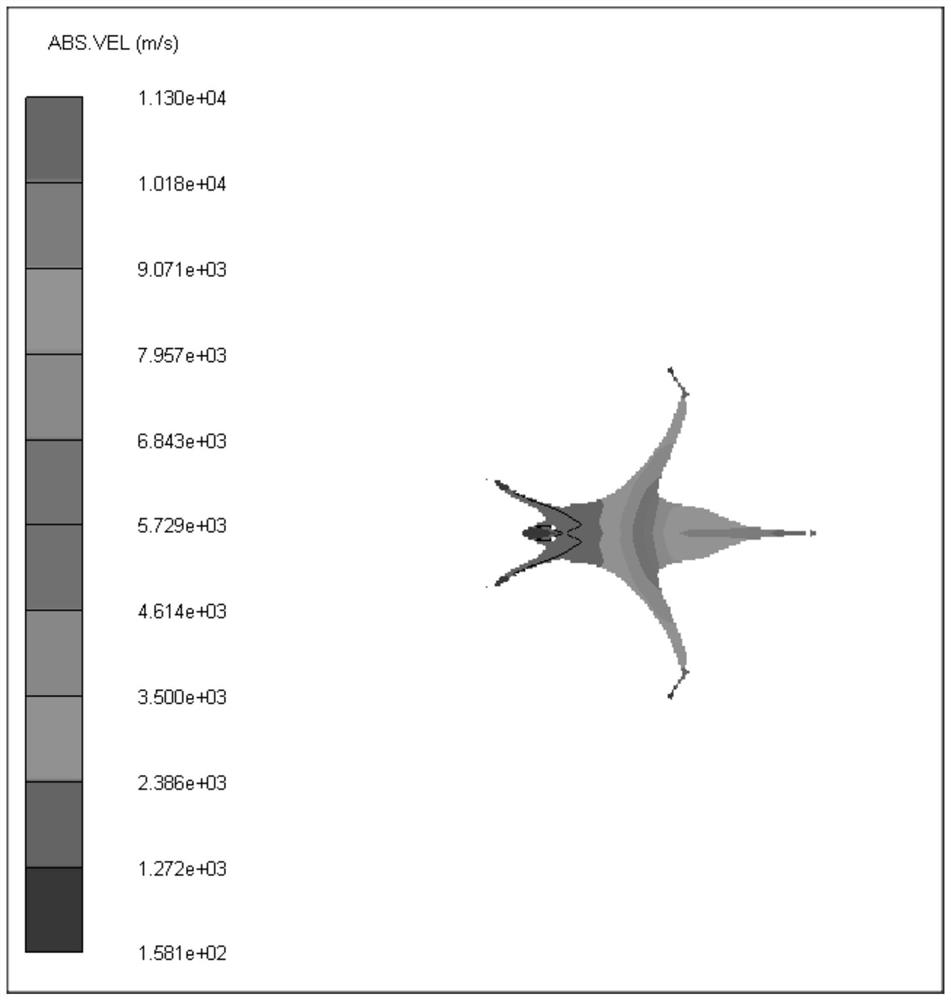

Novel efficient energy-gathering cutting device

The invention provides a novel efficient energy-gathering cutting device. The novel efficient energy-gathering cutting device comprises a charging housing, a shaped charge liner, an auxiliary structure and a charge. The charging housing is of a plate structure with an n-shaped section. The shaped charge liner comprises a shaped charge liner I and a shaped charge liner II. The shaped charge liner Iand the shaped charge liner II are of plate structures, the lower ends of the shaped charge liner I and the shaped charge liner II are connected to the front end of the inner wall of the charging housing, separately, and shaped charge liner connecting plates are arranged at the upper ends of the shaped charge liner I and the shaped charge liner II; the auxiliary structure is of a square plate structure and is arranged on the shaped charge liner connecting plates; and the charge is arranged in a cavity formed by the charging housing, the shaped charge liner and the auxiliary structure. By changing the angle between the shaped charge liner and the charging housing primarily and additionally mounting the auxiliary mechanism on the shaped charge liner, an enough explosive penetration abilitycan be obtained.

Owner:DALIAN UNIV OF TECH

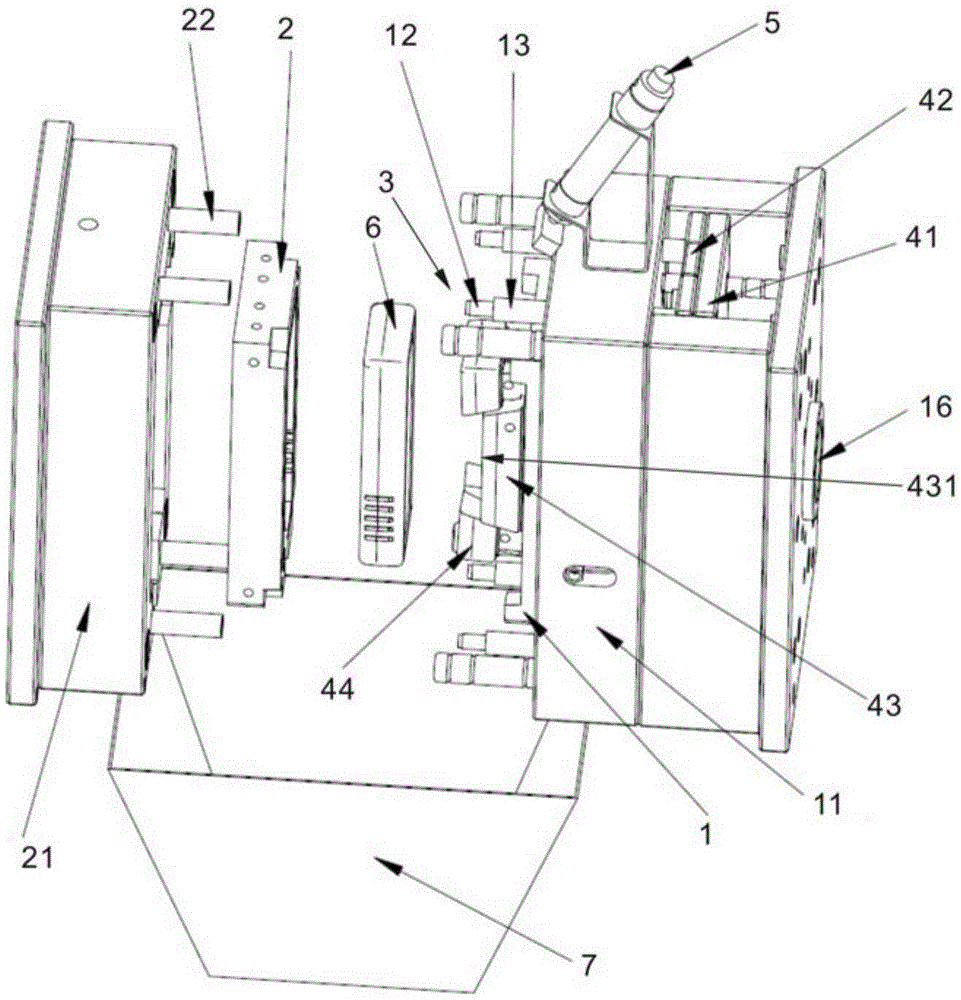

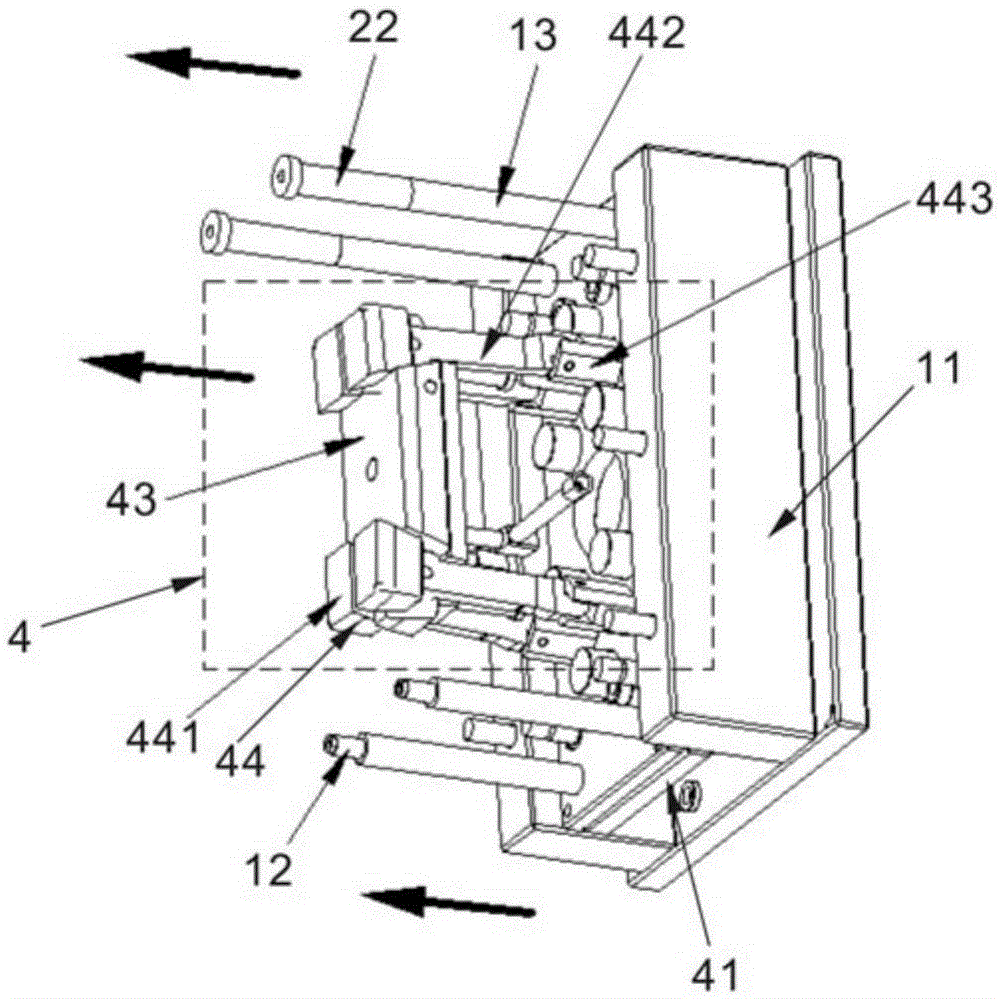

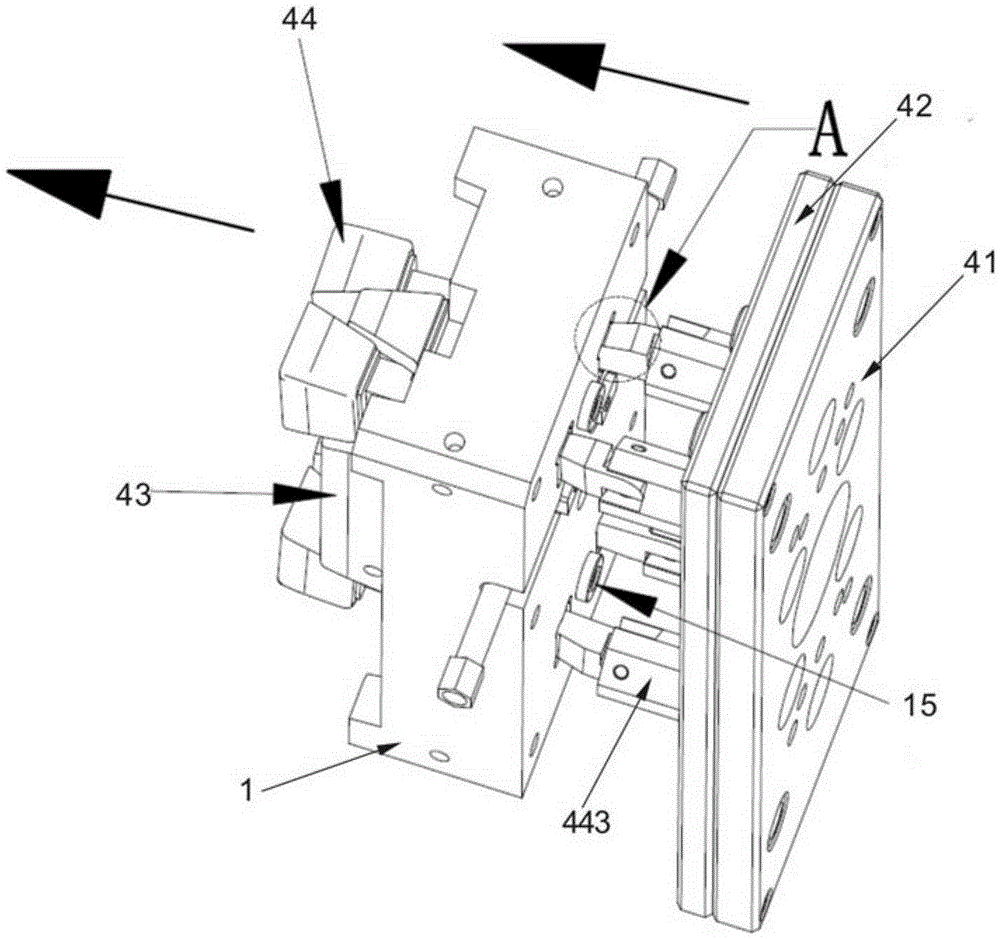

Automatic demolding reverse injection mold and use method

The invention provides an automatic demolding reverse injection mold and a use method. The mold comprises an upper mold body, a lower mold body, an upper mold plate for fixing the upper mold body and a lower mold plate for fixing the lower mold body. The mold further comprises an ejection mechanism. The ejection mechanism comprises a movable mold core for moving a product and an ejector pin plate for pushing the movable mold core to move. The ejector pin plate and the movable mold core are located on the two sides of the upper mold body respectively. The ejector pin plate is provided with multiple shutters for being connected with the lower mold plate. Multiple sleeves are arranged on the portions, corresponding to the shutters, of the lower mold plate. Each sleeve is arranged on the corresponding shutter in a sleeving manner to form containing space for containing the lower mold body and the upper mold body. The product can be subjected to rapid demolding and is not likely to be deformed or damaged, and more importantly, production cost is low.

Owner:为升科(上海)科技电子有限公司

Intelligent parking lot control management system

InactiveCN108133526AVarious payment methodsEasy to replaceTicket-issuing apparatusReservationsMicrocomputerMicrocontroller

The invention provides an intelligent parking lot control management system. The system comprises a parking lot server, an image collector, a ground lock and a GPS (global positioning system) navigation system, wherein the image collector can be used for collecting a license plate number image of a vehicle and transmitting the license plate number image to the parking lot server and a cloud service center to verify; opening and closing a gate machine can be realized accordingly through using the parking lot server to control a single-chip microcomputer; the intelligent parking lot system provided by the invention can be used for making an appointment to park through an APP and automatically identifying and charging a license plate, payment modes are diverse, replacement and maintenance areeasy, and the in-and-out information of each vehicle can be looked over.

Owner:友为技术有限公司

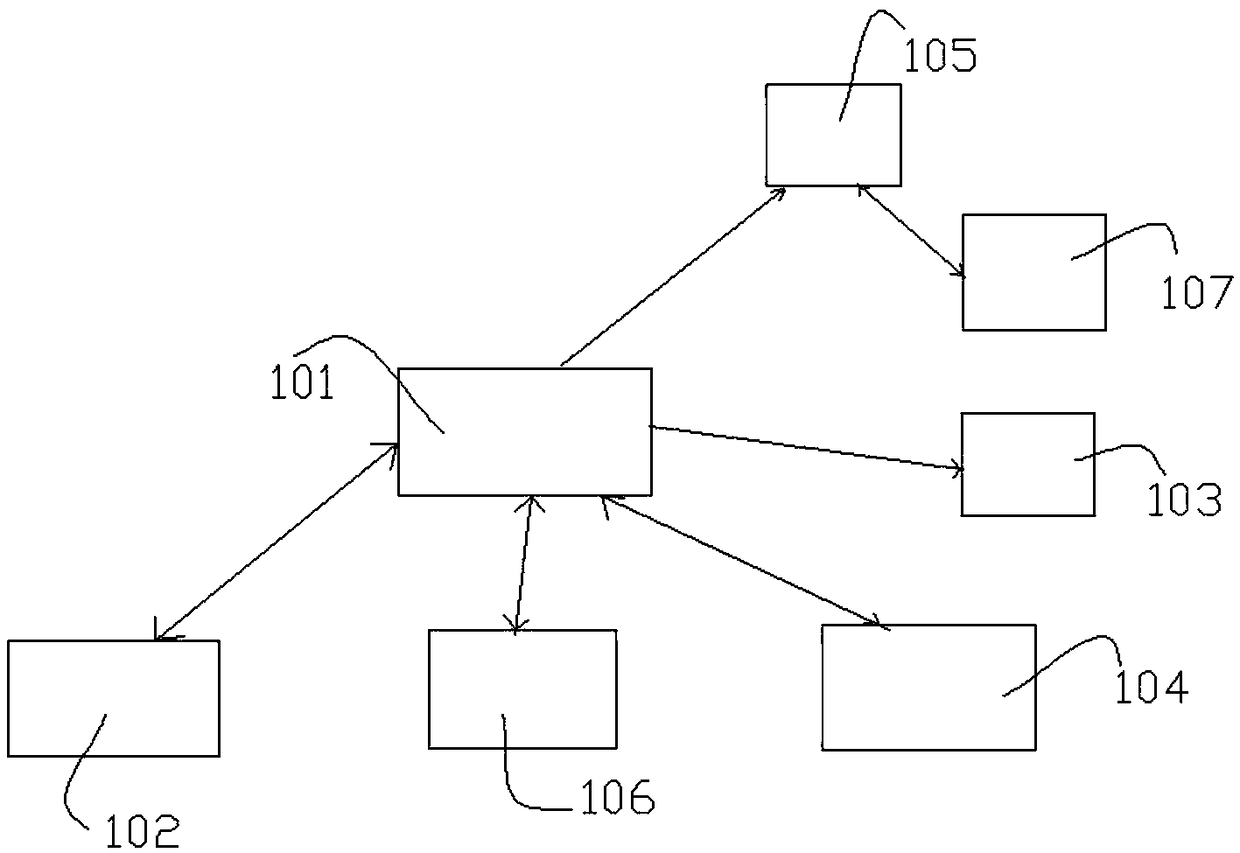

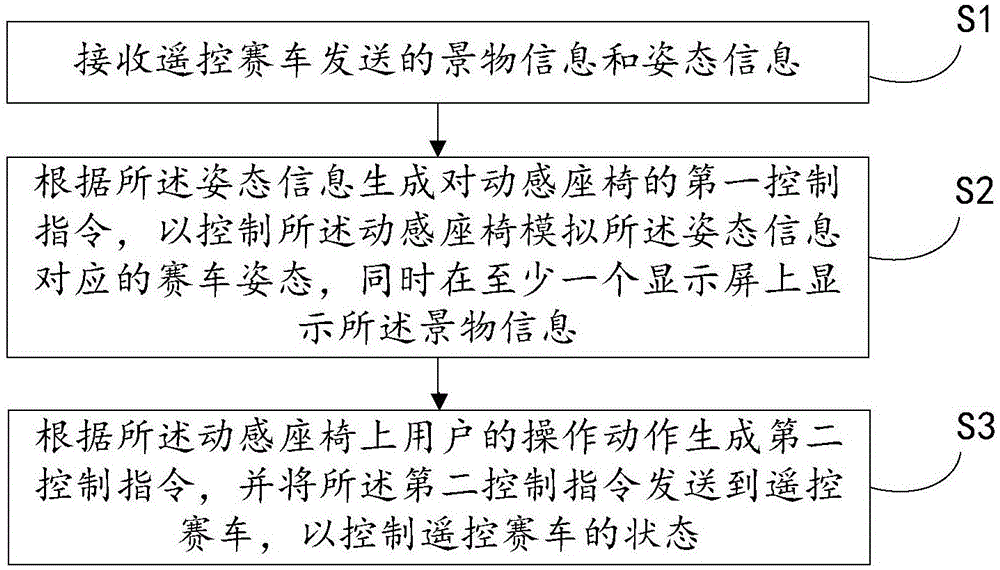

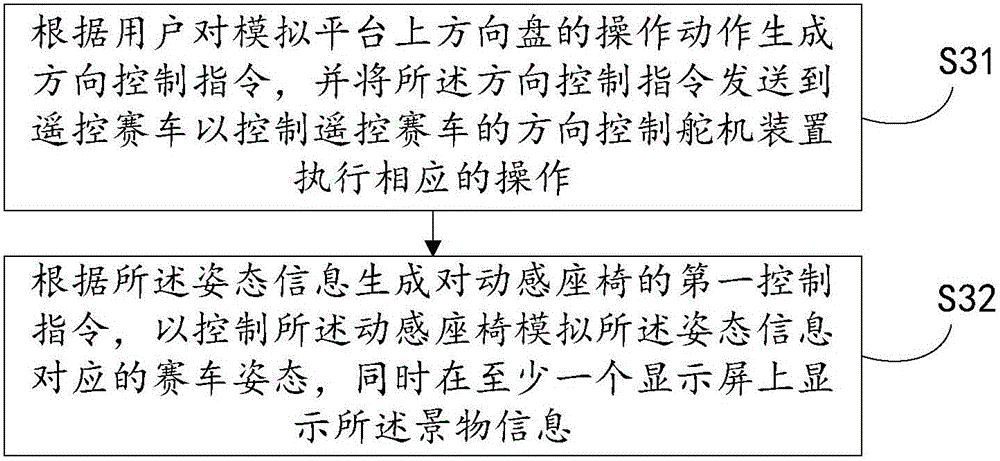

Simulation method and system of racing car operation

ActiveCN106621325AImprove immersionAvoid the shortcoming of the short viewing distance of the third perspectiveVideo gamesSimulationVisual angle

The invention relates to a simulation method and system of racing car operation. The method comprises the following steps: receiving scene information and attitude information, which are sent by a remote racing car; generating a first control instruction of a dynamic seat according to the attitude information, so as to control the dynamic seat to dynamically simulate a racing car attitude corresponding to the attitude information; meanwhile, displaying the scene information on at least one display screen; and generating a second control instruction according to operation action of a user on the dynamic seat and sending the second control instruction to the remote racing car, so as to control the state of the remote racing car. According to the simulation method and system, provided by the invention, the scene information and the attitude information, which are sent by the remote racing car, are received, and first visual-angle display is realized; the disadvantage that a sight distance of a third visual angle is short is avoided and a user has the sensor of immersion; meanwhile, scenes in front of the racing car can be displayed in real time through the display screen and the state of the racing car is changed through user operation; and the state of the racing car is fed back to the dynamic seat, so that the user has a direct feeling, and the sense of immersion is increased when the user plays a game.

Owner:MOTUS TECHNOLOGIES INC

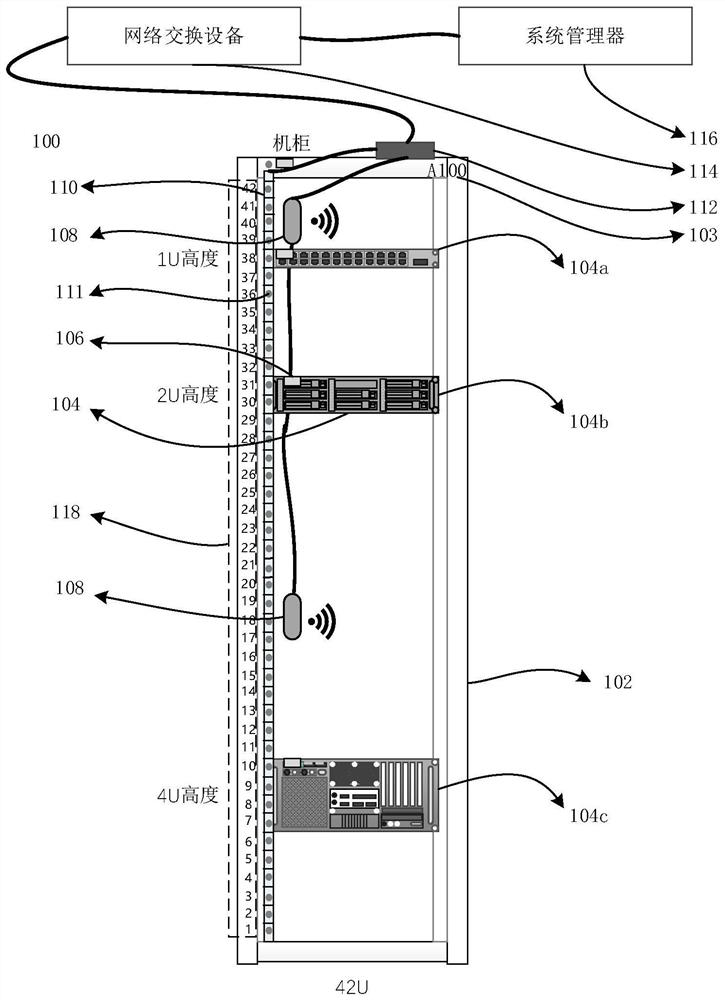

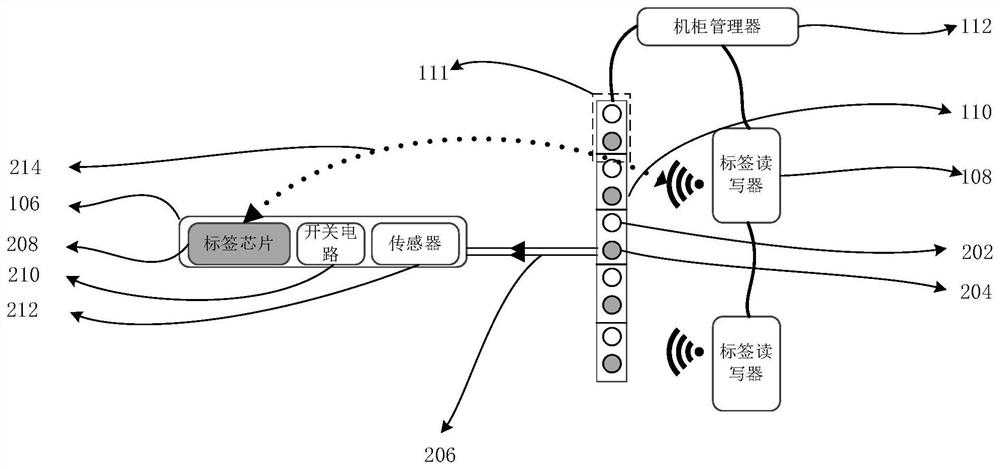

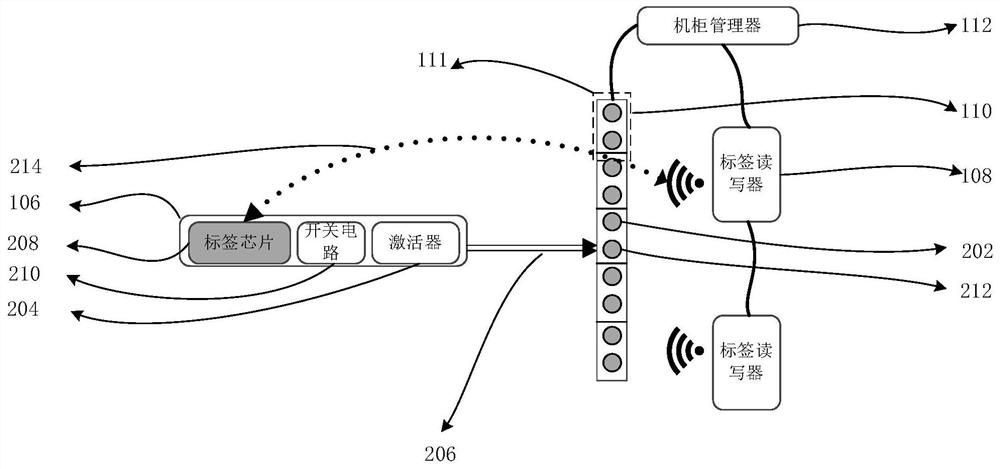

Cabinet, system, method and management suite for equipment information management

PendingCN113806186AControl statusGuaranteed accuracyCo-operative working arrangementsHardware monitoringSoftware engineeringIntelligent management

The invention discloses a cabinet, a system, a method and a management suite for equipment information management. The cabinet is used for loading at least one computer device, and each computer device is loaded at a U position in the cabinet; a label module is installed on each computer device, and each label module is used for storing device information of the corresponding computer device; the cabinet is also provided with a cabinet manager, and the cabinet manager is used for acquiring the equipment information of the computer equipment stored in the label module in the activated state at present; and the cabinet is further provided with a position indicating device, and the position indicating device is used for indicating the U position where the computer equipment corresponding to the label module in the activated state currently is located to the cabinet manager. The cabinet can realize accurate positioning of computer equipment in the cabinet, accurate inventory of computer equipment assets, efficient maintenance of computer equipment information, and intelligent management of computer equipment assets.

Owner:XFUSION DIGITAL TECH CO LTD

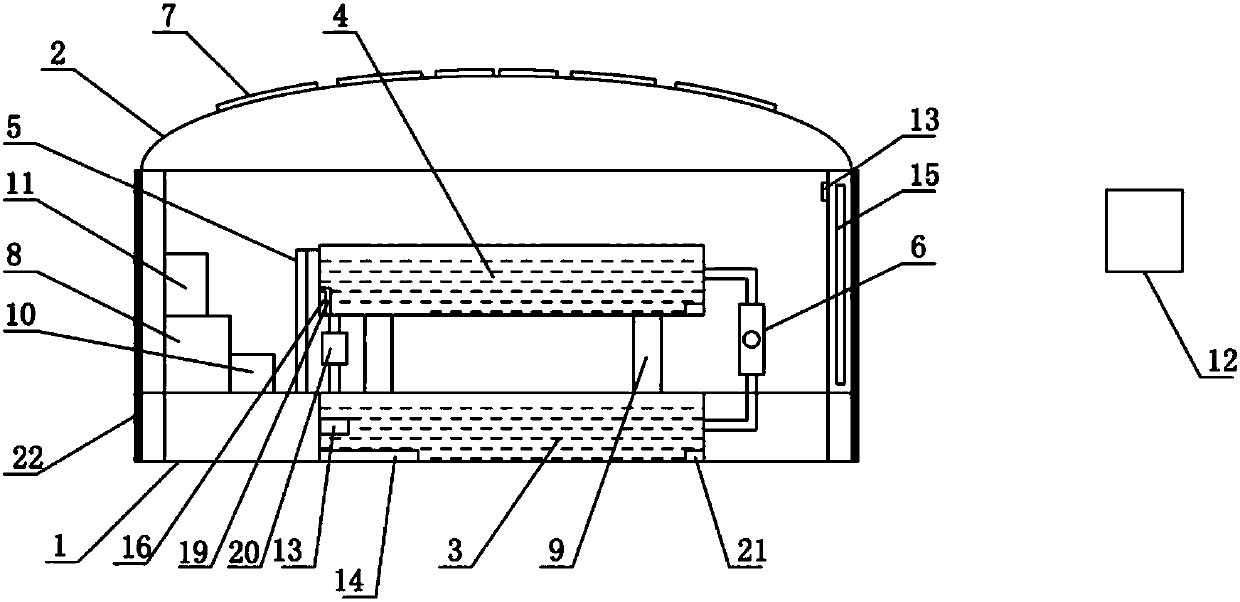

A heat recovery low energy consumption constant temperature swimming pool

ActiveCN105839952BImprove space utilizationIncrease oxygen contentRoof covering using slabs/sheetsRoof covering using tiles/slatesMarine engineeringThermostat

The invention discloses a heat recovery and low energy consumption constant temperature swimming pool. The heat recovery low energy consumption constant temperature swimming pool includes a wall, the upper part of the wall is connected by a transparent roof, and the transparent roof and the wall jointly surround the swimming pool. In the closed space, there is a lower swimming pool located on the ground, and an upper swimming pool is suspended above the lower swimming pool, and the upper swimming pool and the lower swimming pool are connected by columns. The swimming pool is connected with a climbable horizontal bar, the upper swimming pool and the lower swimming pool are provided with filters, the transparent roof is provided with a thin-film solar panel, and the thin-film solar panel is connected with a storage battery. The lower swimming pool and the upper swimming pool are respectively equipped with a first electric heater, a temperature controller, a controller and a heat energy recovery device; the invention has a simple structure, is convenient to use, can recover heat energy, maintains a constant water temperature in the swimming pool, and is energy-saving and environmentally friendly.

Owner:JIANGSU MARITIME INST

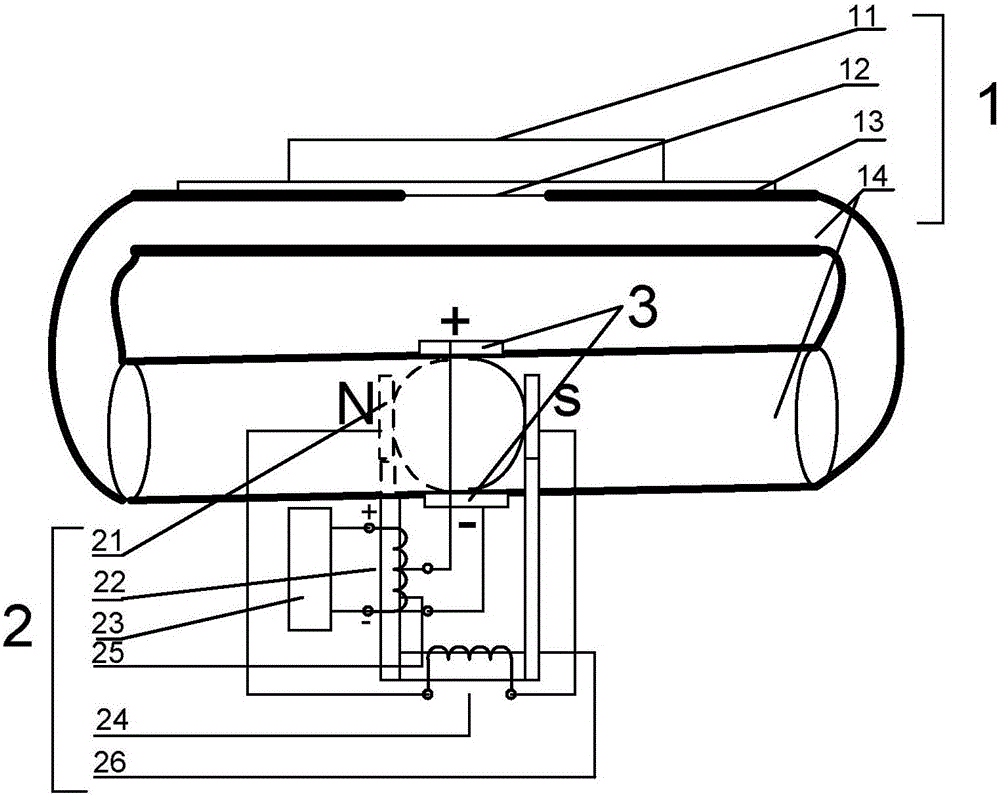

DC converter valve with pulse excitation device

ActiveCN106533131AControl flow rateControl statusCooling/ventilation/heating modificationsPower conversion systemsLiquid metalEngineering

The invention relates to a DC converter valve with a pulse excitation device. The DC converter valve comprises a liquid metal heat exchange assembly, a pulse excitation assembly and a DC electric field switch, wherein the liquid metal heat exchange assembly and the pulse excitation assembly are connected through the DC electric field switch, the liquid metal heat exchange assembly comprises an insulation heat conduction layer, an insulation leather pipe and a liquid metal, an outer peripheral of a DC converter valve body is wrapped in the insulation heat conduction layer, an inner wall of the insulation heat conduction layer contacts with an outer wall of the DC converter valve body, an outer peripheral of the insulation heat conduction layer is wrapped in the insulation leather pipe, the liquid metal is filled into a gap between the insulation leather pipe and the insulation heat conduction layer, the pulse excitation assembly comprises a pulse transformer, a tap joint, a PWM PDM controller and a secondary pulse winding, and the PWM PDM controller is sequentially electrically connected with the pulse transformer, the tap joint and the secondary pulse winding. Compared with the prior art, the DC converter valve is advantaged in that the PWM is employed to control heat radiation of the liquid metal, and the DC converter valve further has properties of high flexibility, high efficiency, small size, low power consumption and long service life.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com