Diaphragm type hole-variable aerator

An aerator and membrane technology, applied in sustainable biological treatment, aerobic process treatment and other directions, can solve the problems of increased trouble, secondary pollution, easy blockage of micropores, etc. The effect of work efficiency and maintenance workload is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

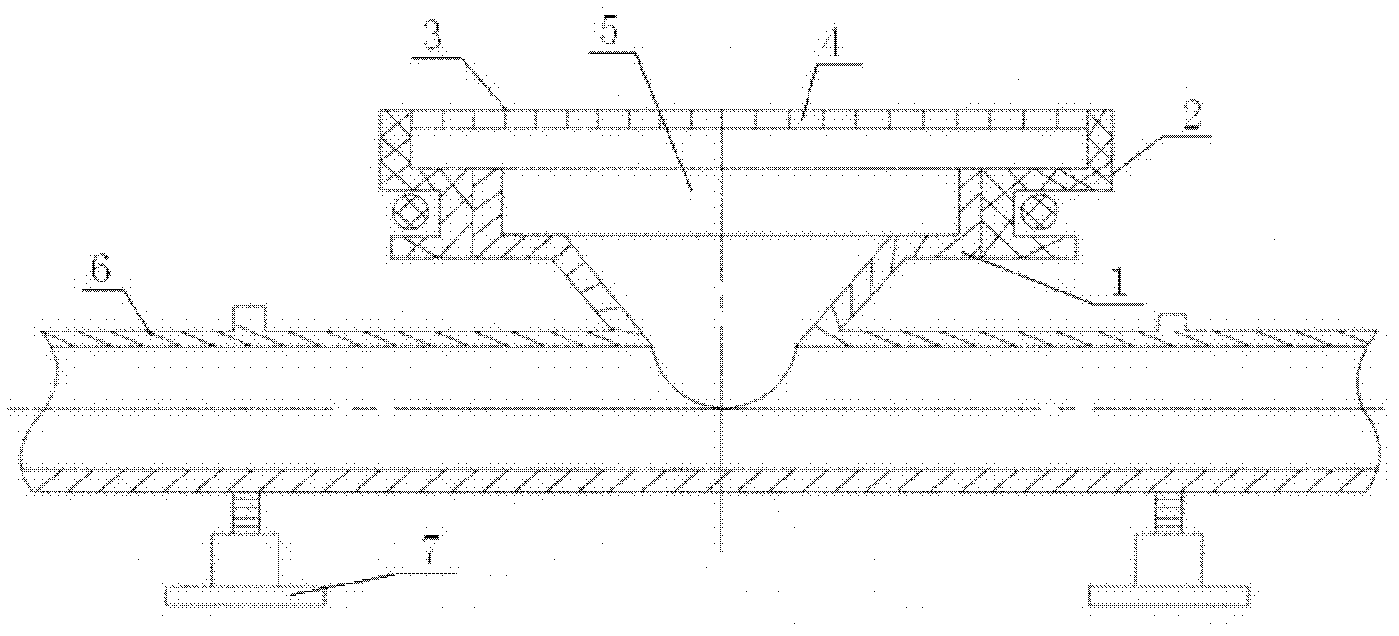

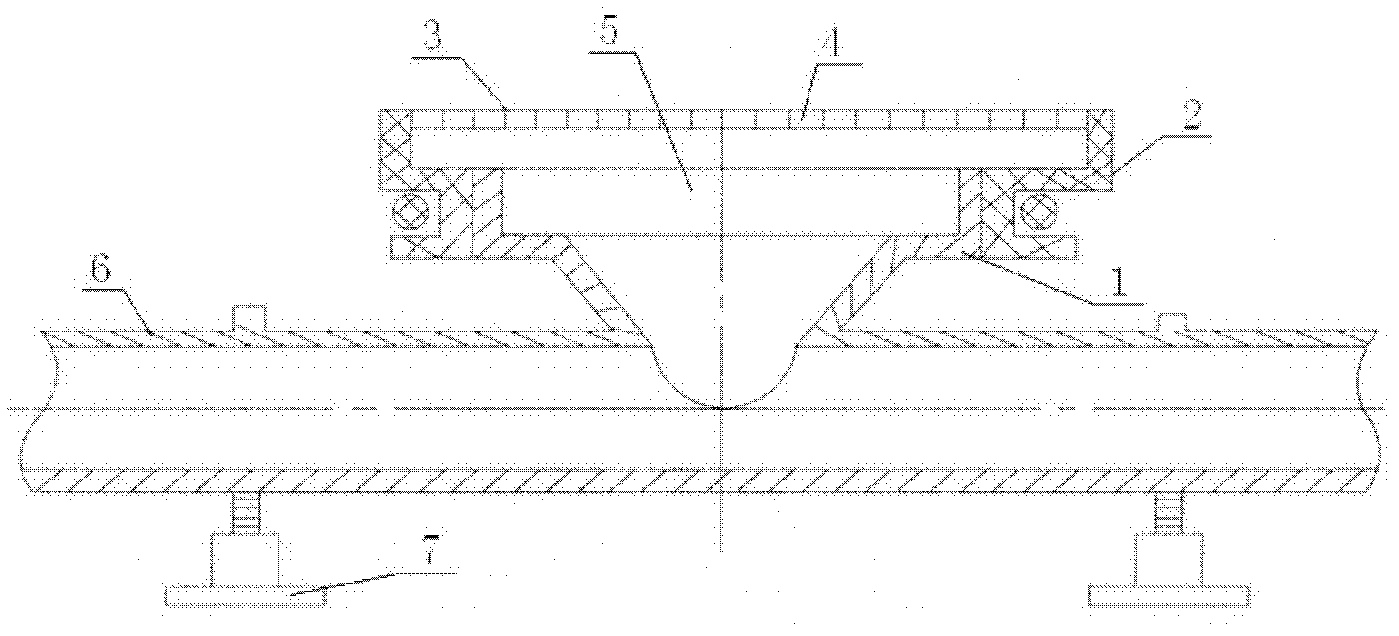

[0015] Such as figure 1 As shown, the diaphragm type variable hole aerator according to the present invention includes a tray 1, an upper cover 2 matched with the tray 1, and a high elastic synthetic rubber diaphragm 3 is arranged on the upper cover 2, A self-closing hole 4 with an aperture of 150-200 microns is provided on the high elastic synthetic rubber diaphragm 3, and the aerator 5 is installed on the ABS air pipe 6, and a level adjuster 7 is provided at both ends of the ABS air pipe 6 The size of the aerator 5 is between 215-260 mm; the self-closing holes 4 are arranged on concentric circles; the tray 1 and the upper cover 2 are made of ABS. The present invention has self-closing holes on the high-elastic synthetic rubber diaphragm, which solves the problem that the holes are easy to be blocked in the past, and adds a level adjustment device to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com