Light guide plate with regional light outlet and manufacturing method thereof

A manufacturing method and technology for a light guide plate, applied in the directions of light guide, optics, optical components, etc., can solve the problems of high manufacturing requirements, low display efficiency, and complicated operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

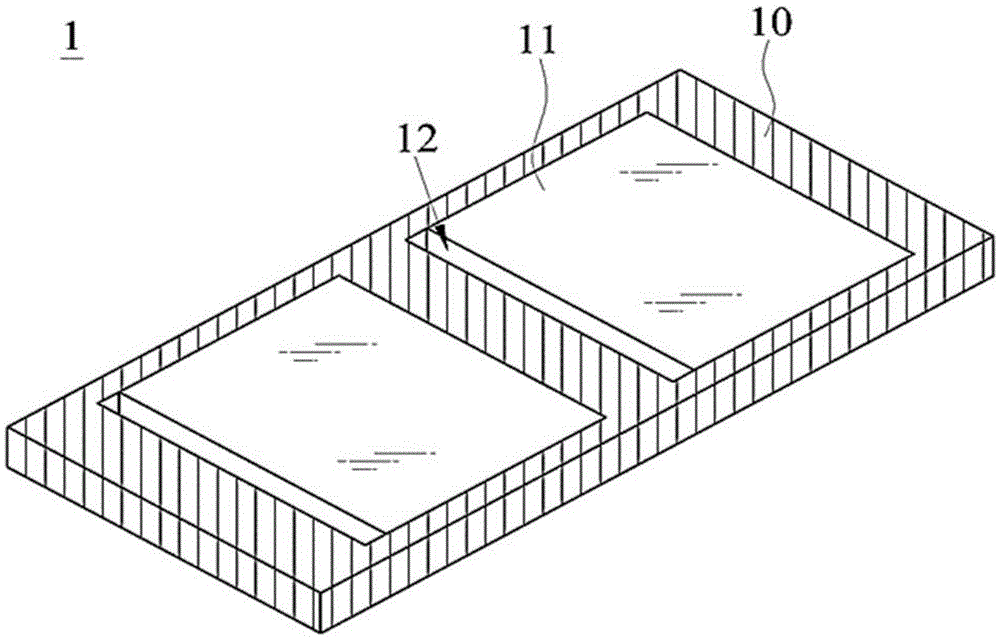

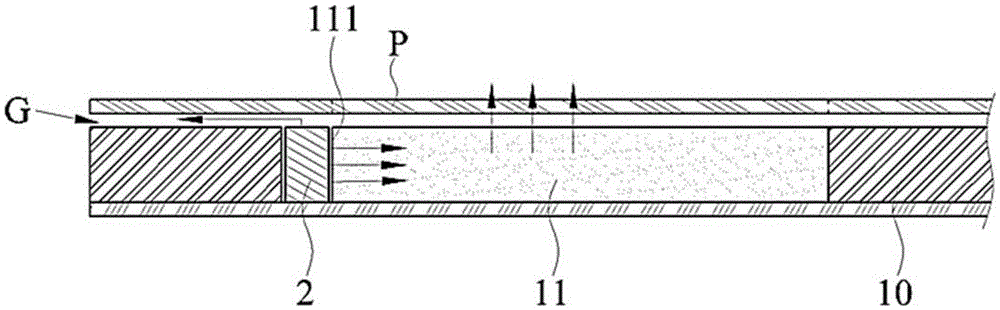

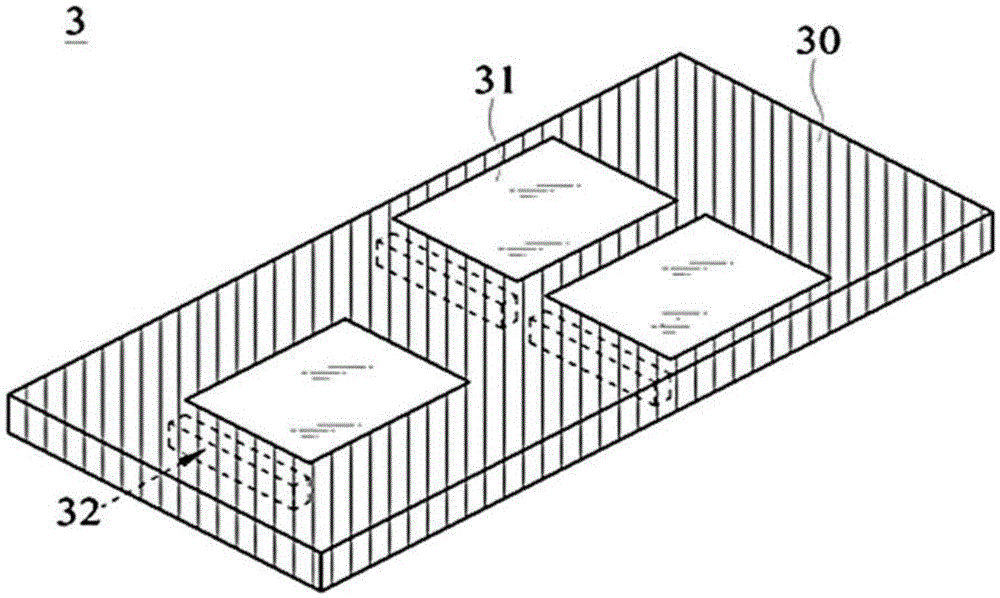

[0132] In view of the fact that the above comparative examples still cannot effectively solve the light leakage phenomenon, the inventors continue to conceive and propose a light guide plate 3 that emits light in areas as described below, which can more effectively control the divergent direction of light through blocking to achieve the shading effect. see Figure 3A , Figure 3B and Figure 4 , which are respectively the three-dimensional structure diagram, the plane structure diagram and the internal structure diagram of the light guide plate according to Embodiment 1 of the present invention. The light guide plate 3 for regional light emission is made by double-material injection molding, and has a light-shielding body 30 and several light-transmitting parts 31. It can be applied to various types of display devices, such as control panels of home appliances, and the light-transmitting member 31 is set corresponding to the position of each pattern on the display panel. Th...

Embodiment 2

[0136] see Figure 7 and Figure 8 , which is a schematic plan view and a schematic view of the internal structure of Embodiment 2 of the present invention. In this embodiment, the specific structure of the light guide plate 5 is further described. The present invention discloses a light guide plate 5 with light-shielding effect, including a light-shielding member 50 and a light-transmitting member 51 .

[0137] The shade 50 has a first stopper 501 and a second stopper 502, the second stopper 502 extends from one side of the first stopper 501, and the second stopper 502 is interposed with the first stopper 501 to form a The light-shielding concave portion 503 . Preferably, the second stopper 502 and the first stopper 501 can be arranged perpendicular to each other, but the present invention is not limited thereto, and the angle between the first stopper 501 and the second stopper 502 can also be adjusted according to requirements.

[0138] The light-transmitting member 51 i...

Embodiment 3

[0142] The present invention also discloses a method for manufacturing a light guide plate that emits light in an area, including the following steps: providing a first male mold core and a female mold core, the female mold core has at least one blind hole block, and then injects a The first material is between the first male mold core and the female mold core, and then, the first male mold core is removed, and a second male mold core is provided; next, a second material is injected between the second male mold core and the female mold core Between the mold cores; finally, exit the blind hole block and perform a demoulding action to obtain a light guide plate, wherein the blind hole block forms a blind hole corresponding to accommodate a light source. In this way, by replacing the two types of male mold cores and combining the setting of blind hole blocks, the light guide plate that emits light from the aforementioned area can be mass-produced and the problem of light leakage c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com