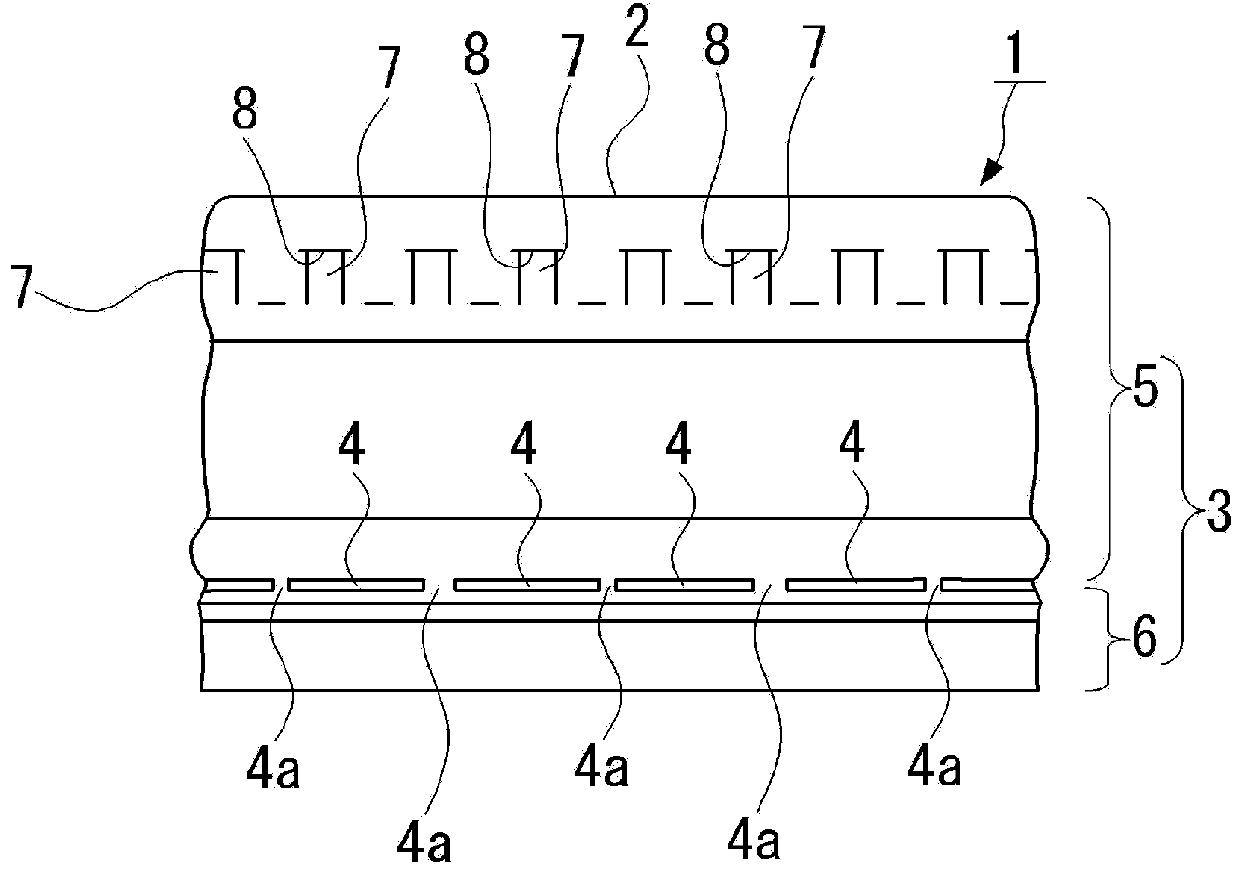

Metal cap and bottle with cap

A metal cover and liner technology, applied in the field of metal covers, can solve the problems of liner falling off, time-consuming and laborious processing, liner wear, etc., and achieve the effects of smooth insertion, smooth grip, and prevention of falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

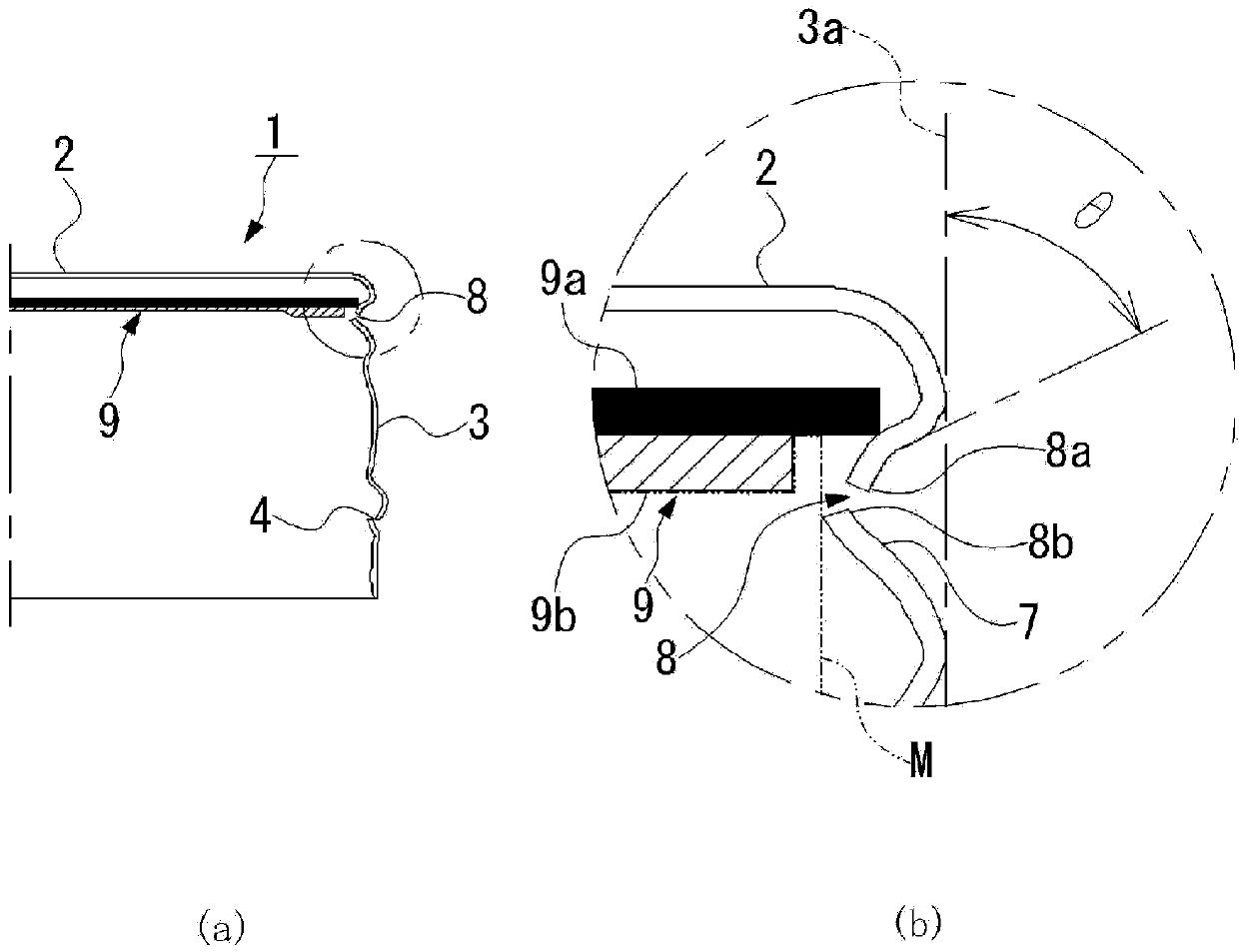

[0041] Next, metal caps and capped bottles according to the present embodiment were actually produced, and the drop-off of the liner at the time of cap opening was evaluated.

[0042] First, when the angle θ of the upper protrusion of the scored slit was varied from 0 to 87° and manufactured, the opened metal cap was visually evaluated, and the upper protrusion and the lower protrusion separated from the liner The number of parts (hereinafter referred to as hooks) and the number of bottles (hereinafter referred to as the number of cans) investigate the frequency of hook detachment and judge whether it is good or bad.

[0043] In addition, the above-mentioned hook detachment frequency is calculated by the following formula. Hook detachment frequency = (number of detached hooks × number of tanks) ÷ number of evaluation tanks, for example, the number of evaluation tanks is 30 tanks, two out of two tanks have detached hooks, three out of three tanks have detached hooks, and three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com