Web center position control device, method and program, and web trimming device

A center position and control device technology, applied in the direction of shearing device, use feedback control, manufacturing tools, etc., can solve difficult problems such as the control of plate and strip snakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

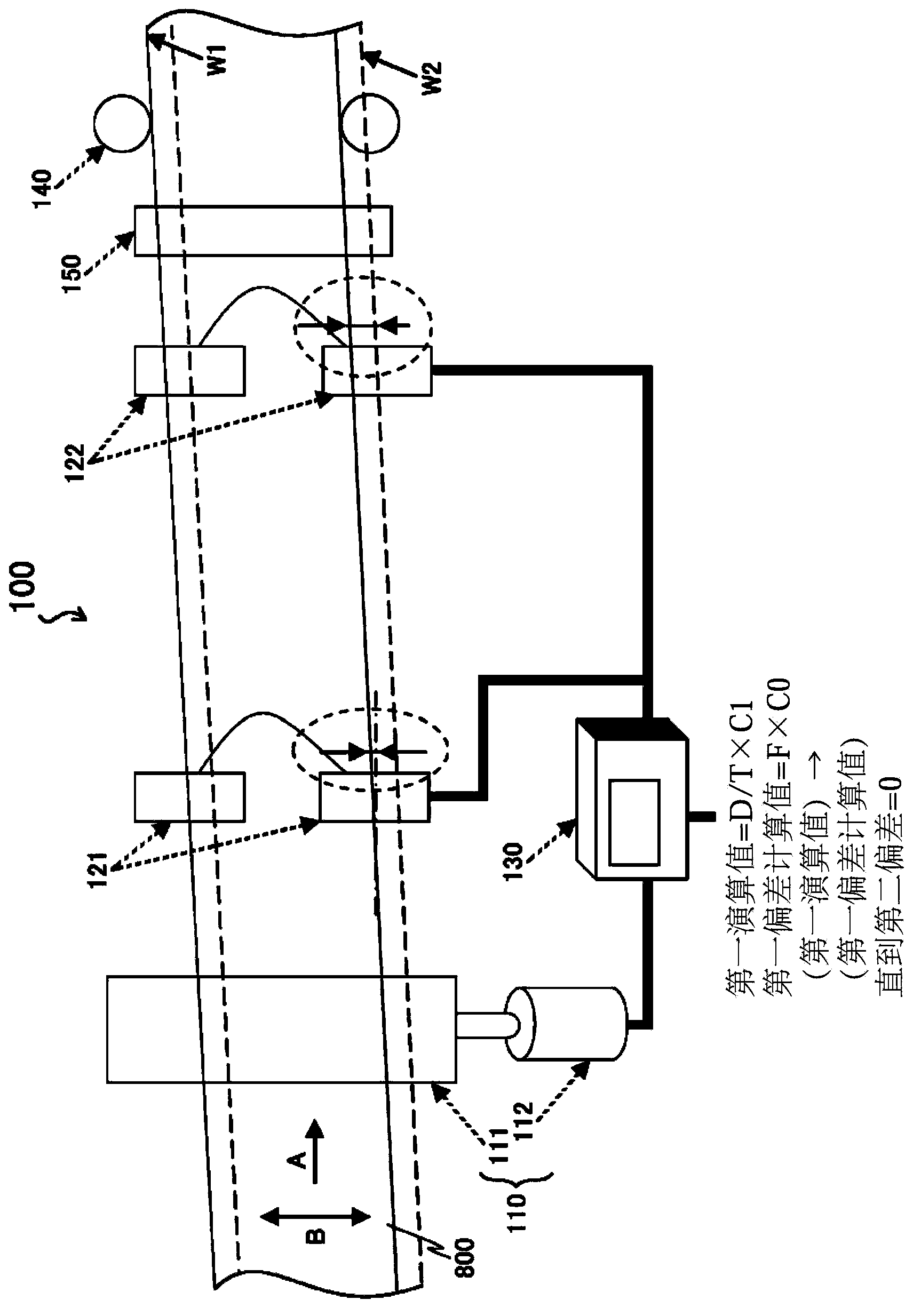

[0086] figure 1 It is a schematic diagram showing the structure of the strip center position control device 100 according to the first embodiment of the present invention.

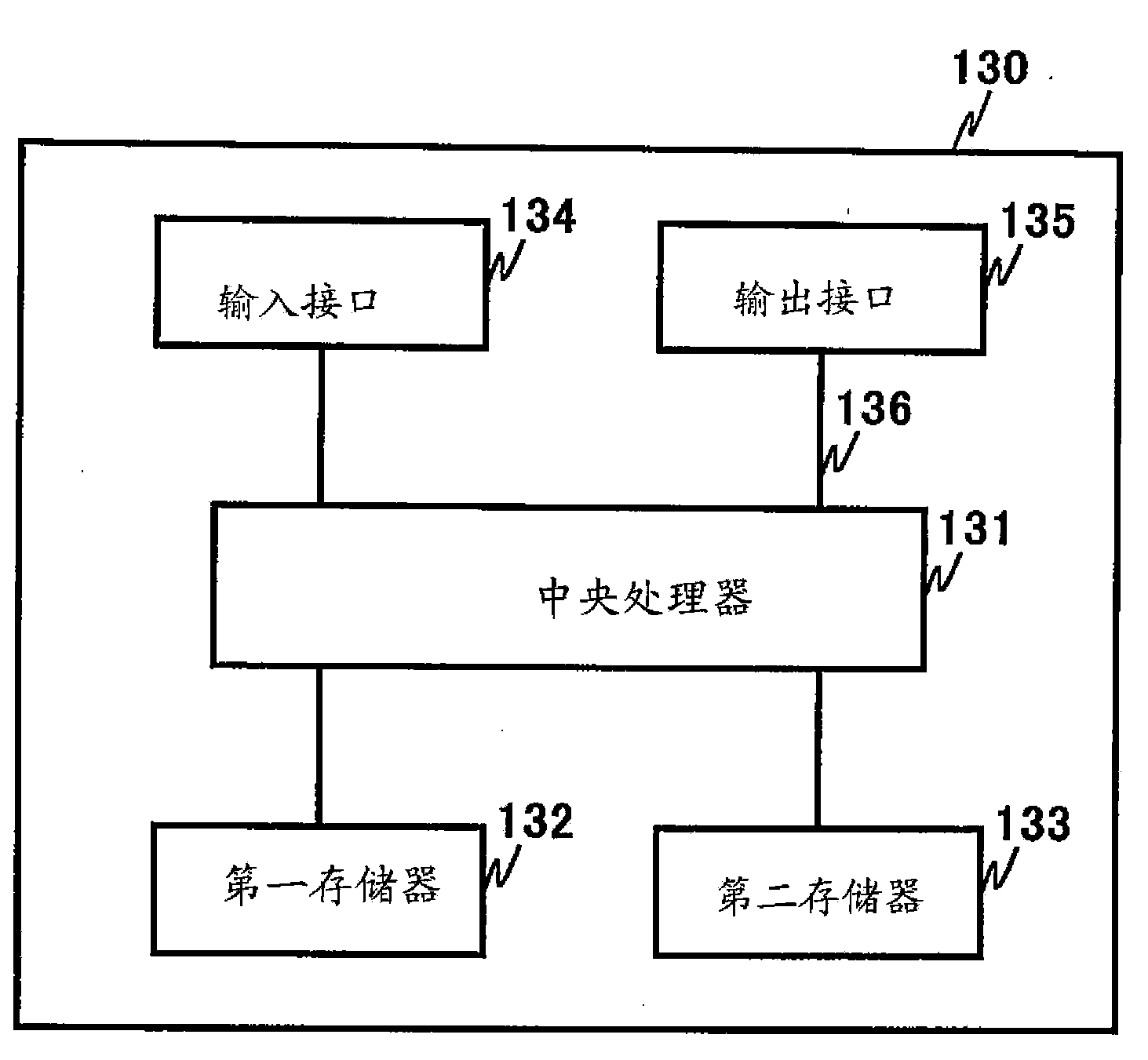

[0087]The strip center position control device 100 according to the present embodiment includes: a center position controller 110 for controlling the position of the center of the strip 800 conveyed in the direction A from upstream to downstream in the width direction B; A first device for detecting the actual center position of the plate material 800 in the width direction B and sending a detection signal indicating the center position is provided downstream of the center position controller 110 in the conveying direction A of the plate material 800 . Sensor 121; disposed downstream of the first sensor 121 in the conveying direction A of the strip material 800, for detecting the actual center position of the strip material 800 in the width direction B and sending a detection signal representing the cente...

no. 2 example

[0123] In the strip center position control device 100 according to the above-mentioned first embodiment, the second deviation / N (N is a positive integer greater than 2) is added to the first deviation at each control unit time, but in the present embodiment In the strip center position control device, instead of the second deviation / N and the first deviation, the meandering control of the strip 800 is implemented using values calculated from the second and first deviations.

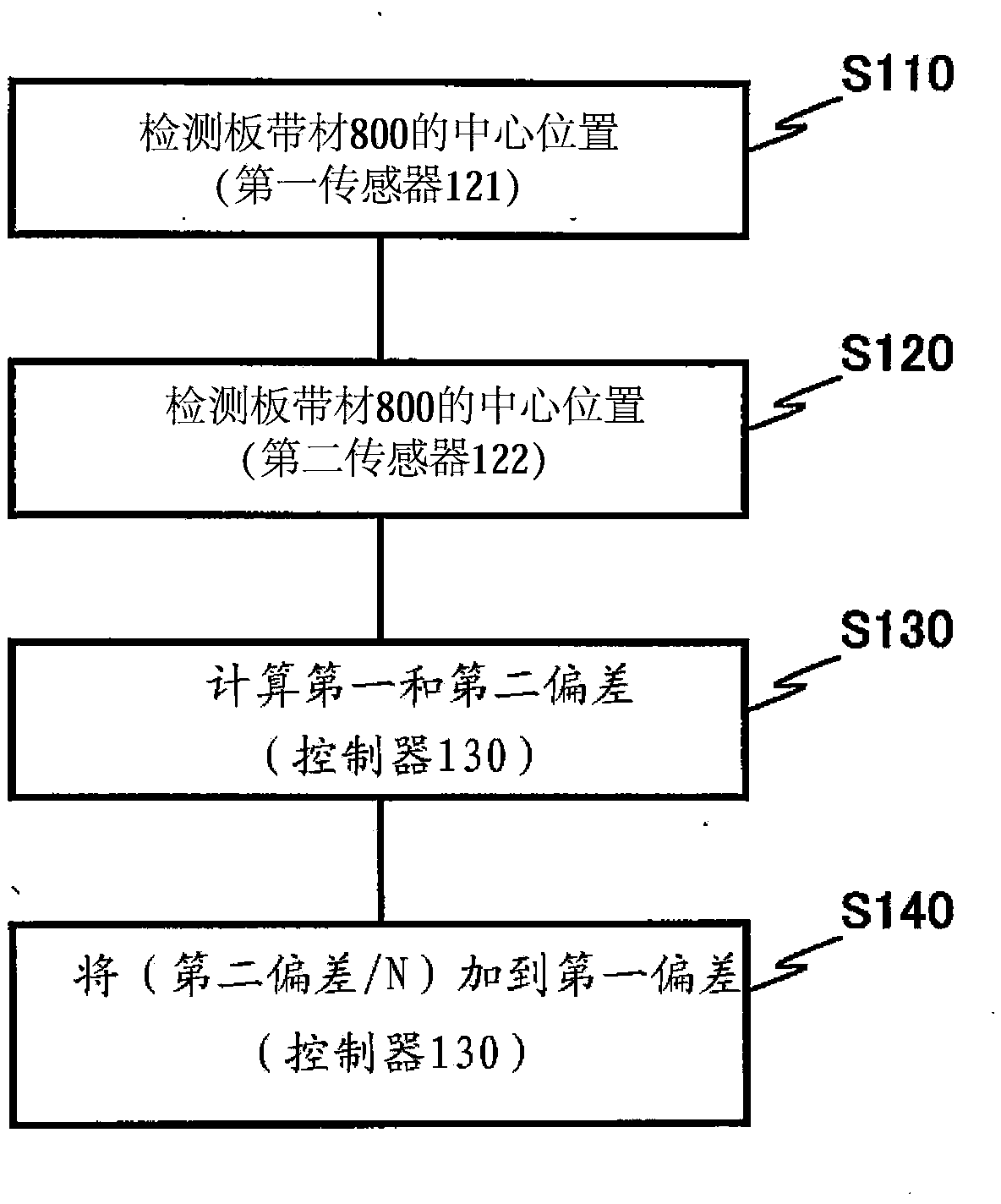

[0124] Figure 5 is a flow chart showing operations performed by the strip center position control device according to the present embodiment.

[0125]After calculating the first and second deviations (step S130), the controller 130 calculates the first calculation value according to formula (1) (step S150), wherein,

[0126] The first calculation value = D / T × C1 (1)

[0127] D: second deviation

[0128] T: value (time) obtained by dividing the distance between the first sensor 121 and the second...

no. 3 example

[0151] The higher the conveying speed of the strip material 800 is, the higher the snaking frequency of the strip material 800 will be, causing the strip material 800 to start to vibrate. When the meandering frequency of the strip 800 is so high, correspondingly, more reliable meandering control of the strip is required. The strip center position control device 200 according to the third embodiment of the present invention described below can reliably perform the strip meandering control even in the case where the meandering frequency of the strip 800 is high.

[0152] Figure 7 It is a schematic diagram showing the structure of the strip center position control device 200 according to the third embodiment of the present invention.

[0153] Compared with the strip center position control device 100 according to the first embodiment, the strip center position control device 200 according to the present embodiment differs only in the operation of the controller 130, and has the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com