A motor rotor assembly structure

A technology of assembly structure and motor rotor, applied in the direction of magnetic circuit shape/pattern/structure, electromechanical device, electrical components, etc., can solve the problem that the keyway cannot be processed symmetrically, reduce the strength of the shaft, increase the processing capacity of the shaft, etc. die cost, reduce total cost, and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

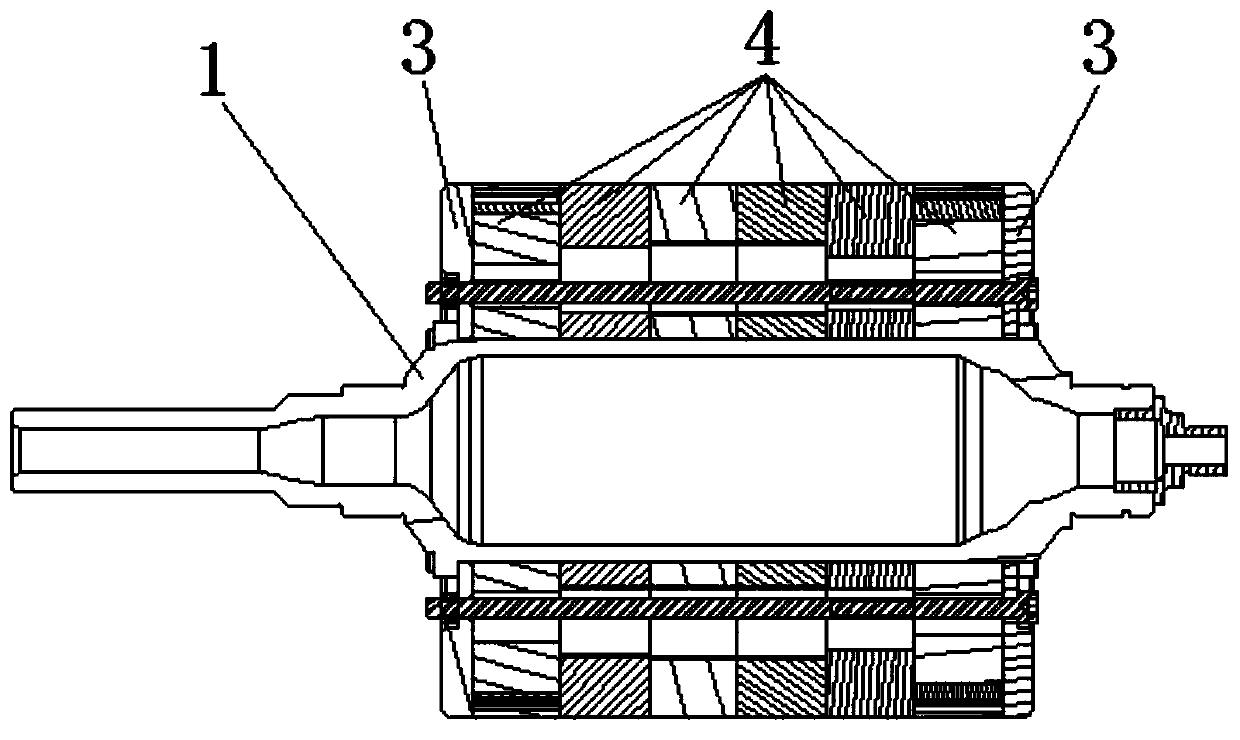

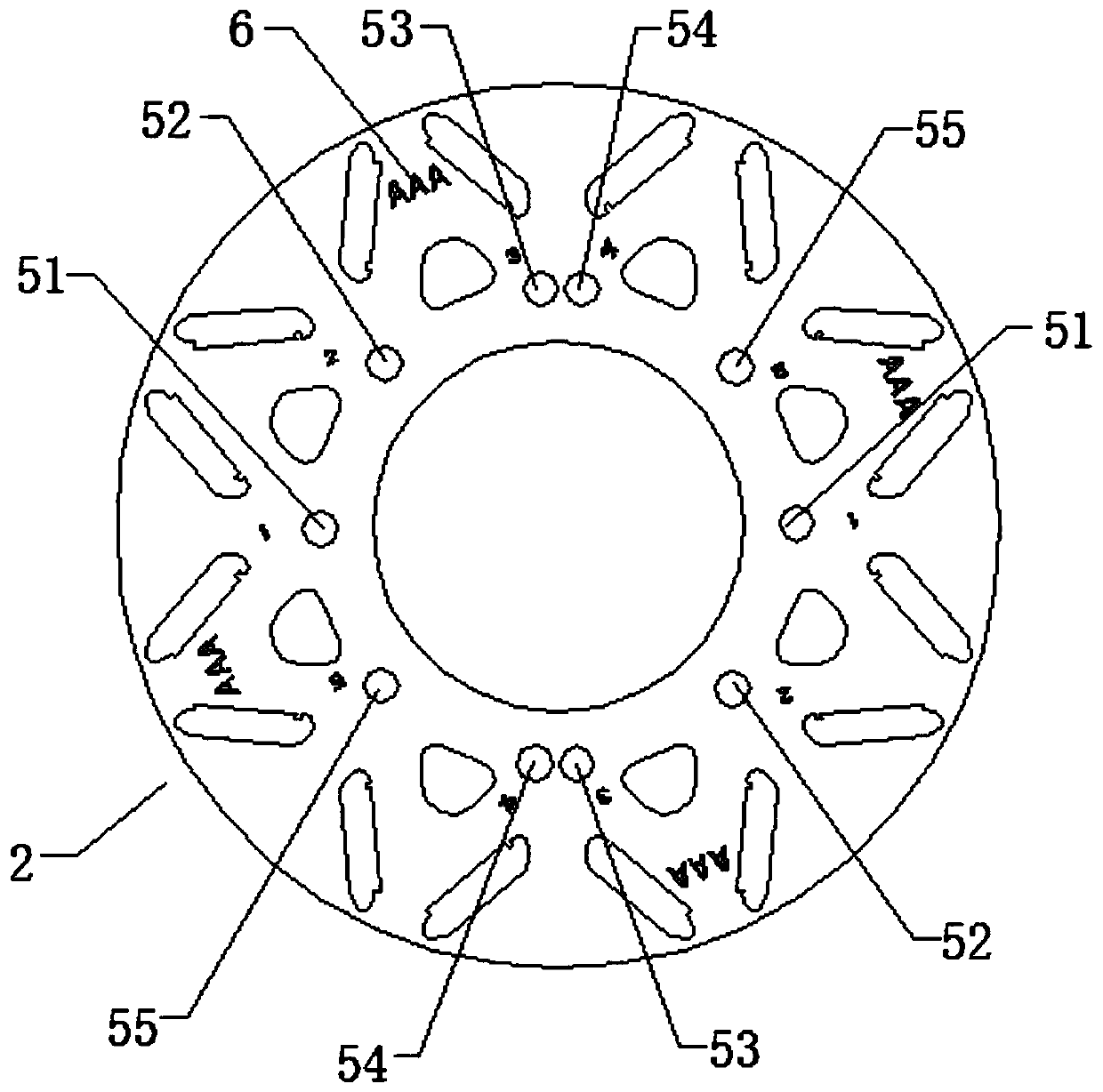

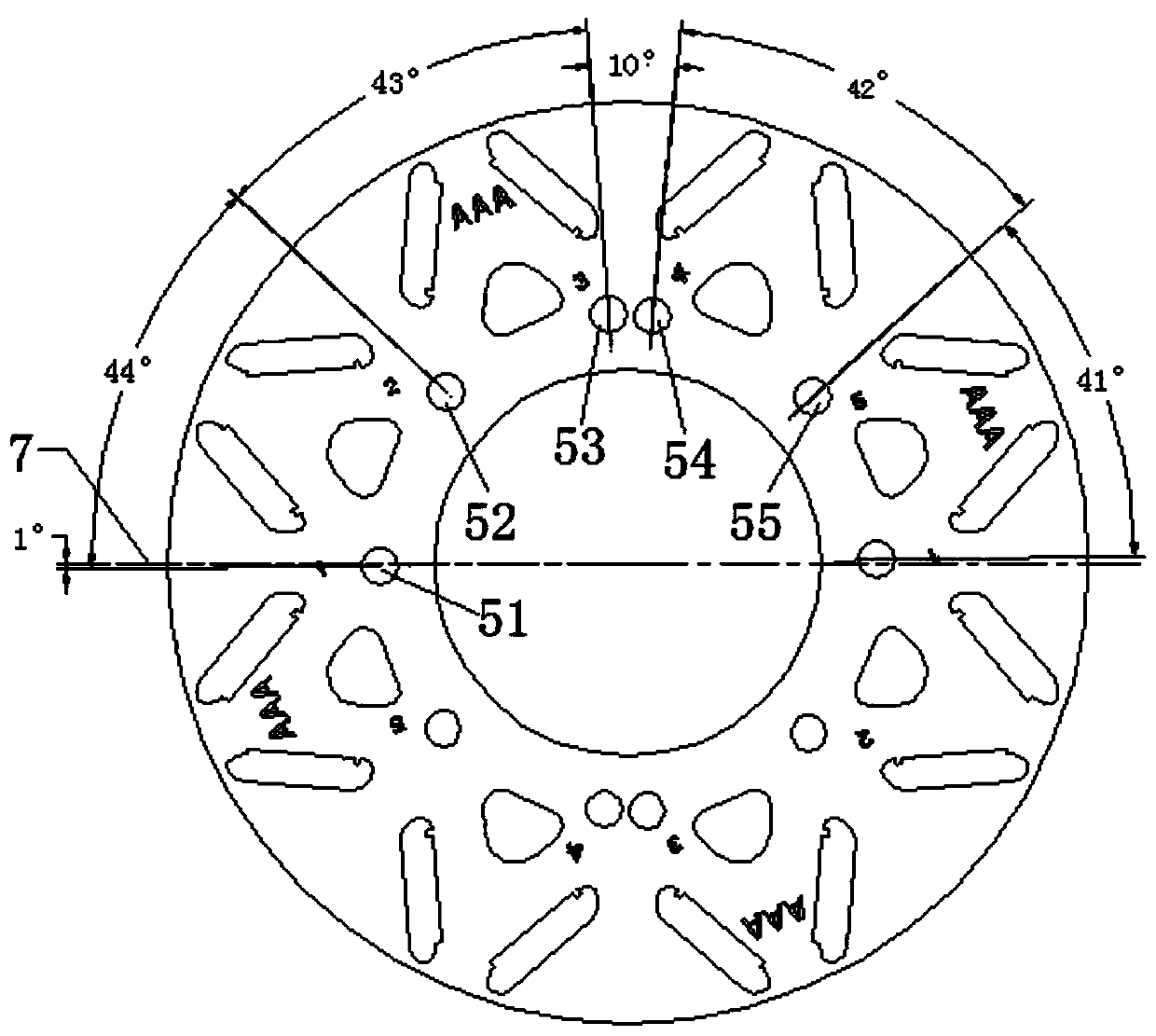

[0021] as attached Figure 1~2 As shown, a motor rotor assembly structure includes a rotating shaft 1, six rotor cores 4 formed by neatly stacking a plurality of rotor punches 2, and two rotor cores installed at the front and rear ends of the whole body composed of six rotor cores 4. Rotor pressing plate 3, the axial middle part of the rotor iron core is provided with a shaft hole for installing the rotating shaft 1, and the two rotor pressing plates 3 are used to compress a plurality of rotor punching plates 2; the rotating shaft 1 is a hollow shaft; The rotor punches 2 have the same structure; each rotor punch 2 has multiple sets of positioning holes; multiple rotor punches 2 are positioned and fixed on the rotating shaft 1 through multiple sets of positioning holes to realize the rotor segment between oblique poles. Each group of positioning holes is composed of two positioning holes symmetrical to the axis of the rotor punching sheet; there are five groups of positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com