Packaging structure and forming method thereof

A packaging structure and plastic sealing layer technology, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve problems affecting the performance of the packaging structure and unstable electrical connections, etc., to improve electrical connection performance, improve accuracy, The effect of preventing loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

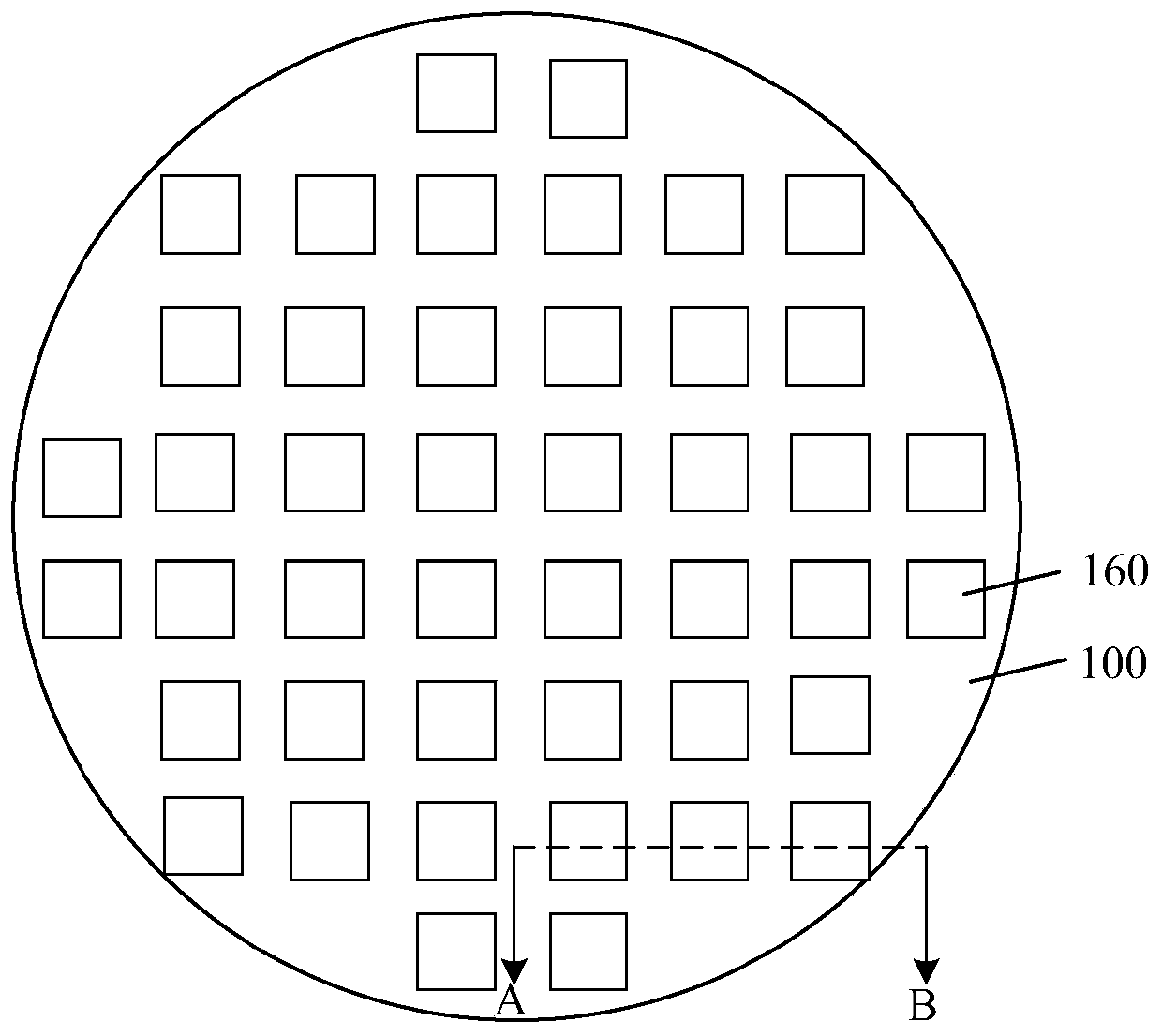

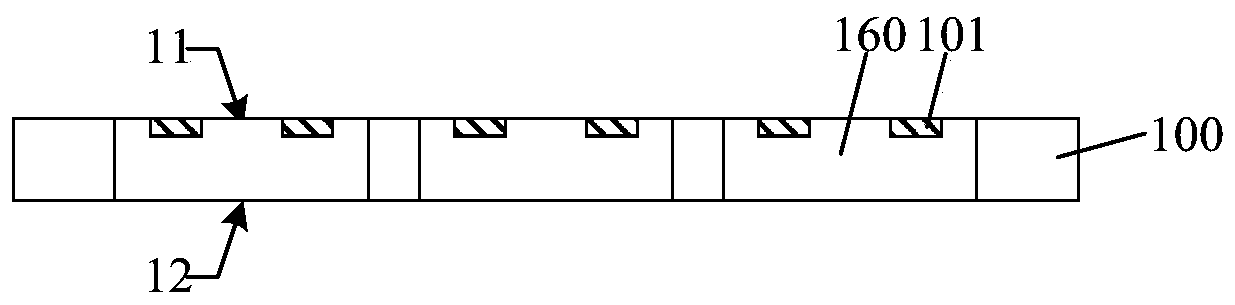

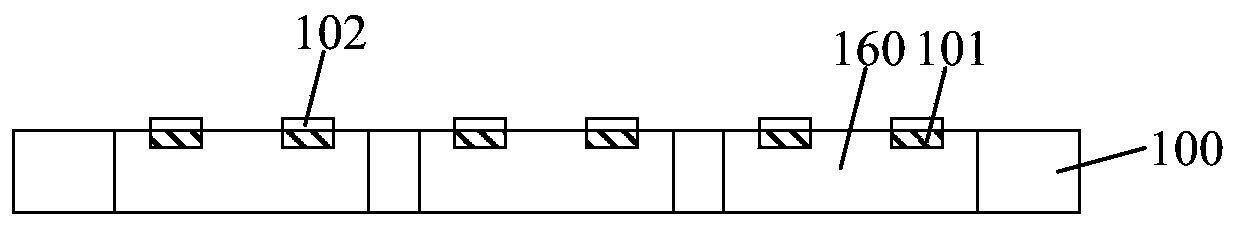

[0043] As mentioned in the background art, in the packaging structure formed by the conventional chip fan-out packaging process, the electrical connection between the rewiring layer and the semiconductor chip is easily unstable, which affects the performance of the packaging structure.

[0044] Research has found that the reason why the electrical connection between the rewiring layer and the semiconductor chip in the existing fan-out packaging structure is easily unstable is that the connection position between the rewiring layer and the pad of the semiconductor chip is shifted.

[0045] Further studies have found that the reason for the offset of the connection position between the rewiring layer and the pads of the semiconductor chip is that there are usually raised metal bumps formed on the pads of the existing semiconductor chips. , the non-functional surfaces (sides without pads) of several semiconductor chips are bonded to the carrier board by adhesive tape or adhesive l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com