Scr system

A technology for selecting catalysis and engine speed, applied in the field of SCR system, which can solve problems such as the inability of the engine to start and the inaccurate management of margins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

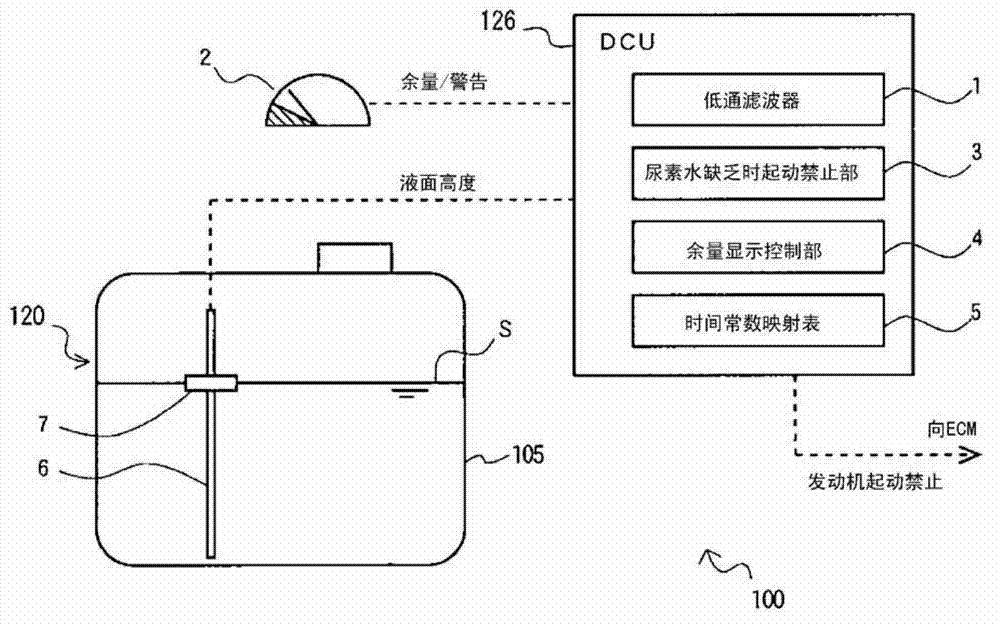

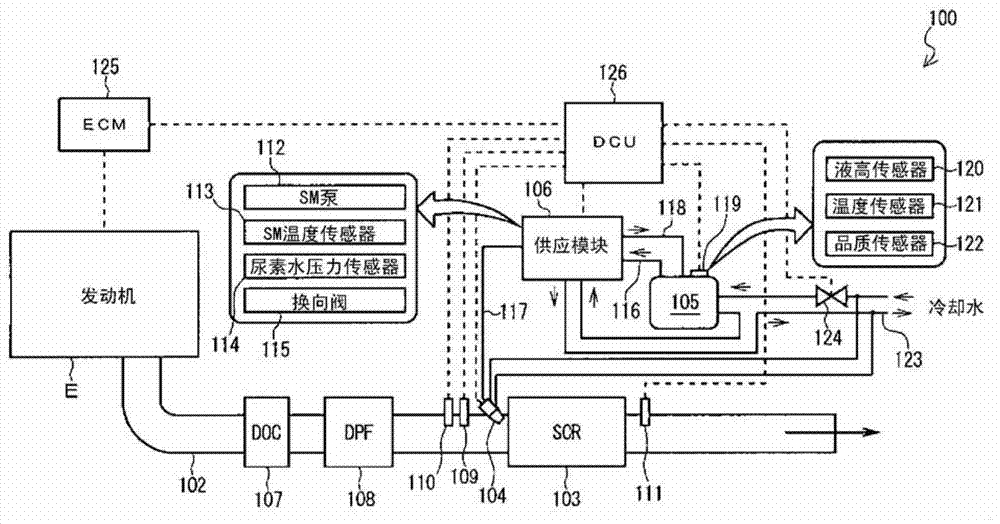

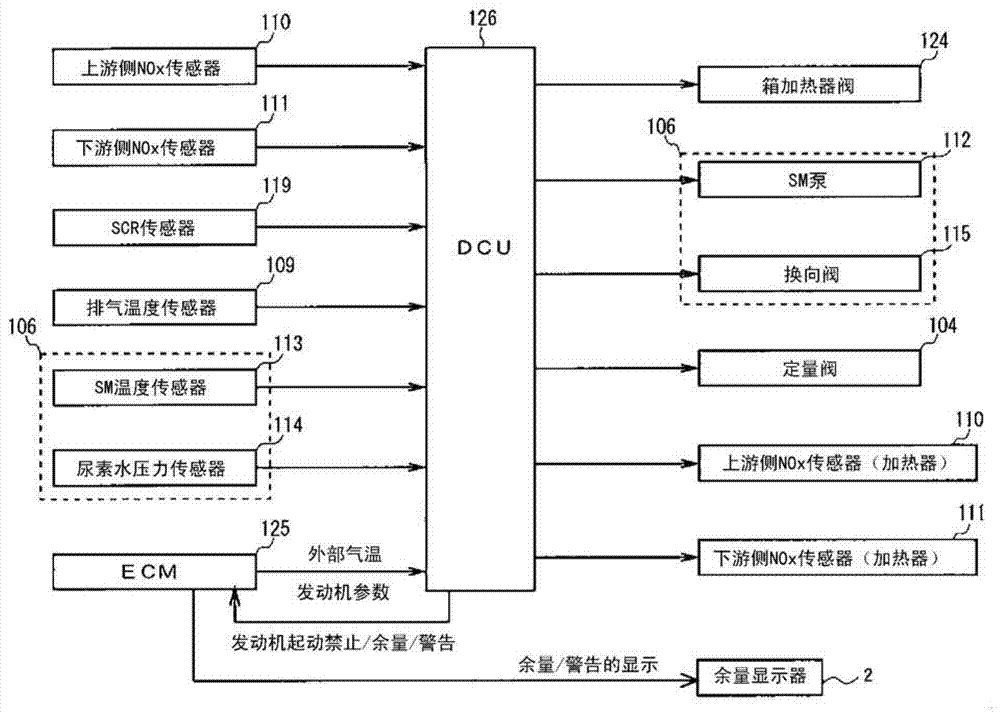

[0026] Such as figure 1 and figure 2 As shown, the SCR system 100 of the present invention has a urea water tank 105, which is used to store the urea water sprayed into the exhaust pipe 102 of the engine E; a liquid height sensor 120, which detects the liquid level height in the urea water tank 105; a low-pass filter 1, has the following signal response characteristics: relative to the output signal of the liquid height sensor 120, the time constant is small when the engine speed is low, and the time constant is large when the engine speed is high; the margin display 2 is based on the low-pass The output signal of the liquid level sensor 120 processed by the filter 1 shows the remaining amount of urea water; and the start prohibition part 3 when the urea water is lacking, prohibits the starting of the engine when the remaining amount of urea water is lower t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com