Corn seed orientation method and device

A directional device and seed technology, which is applied in the directions of seed and rhizome treatment, sowing, application, etc., can solve the problems that corn seeds have not been processed in the early stage, it is difficult to sow directly, mechanized and automated corn directional sowing cannot be carried out, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

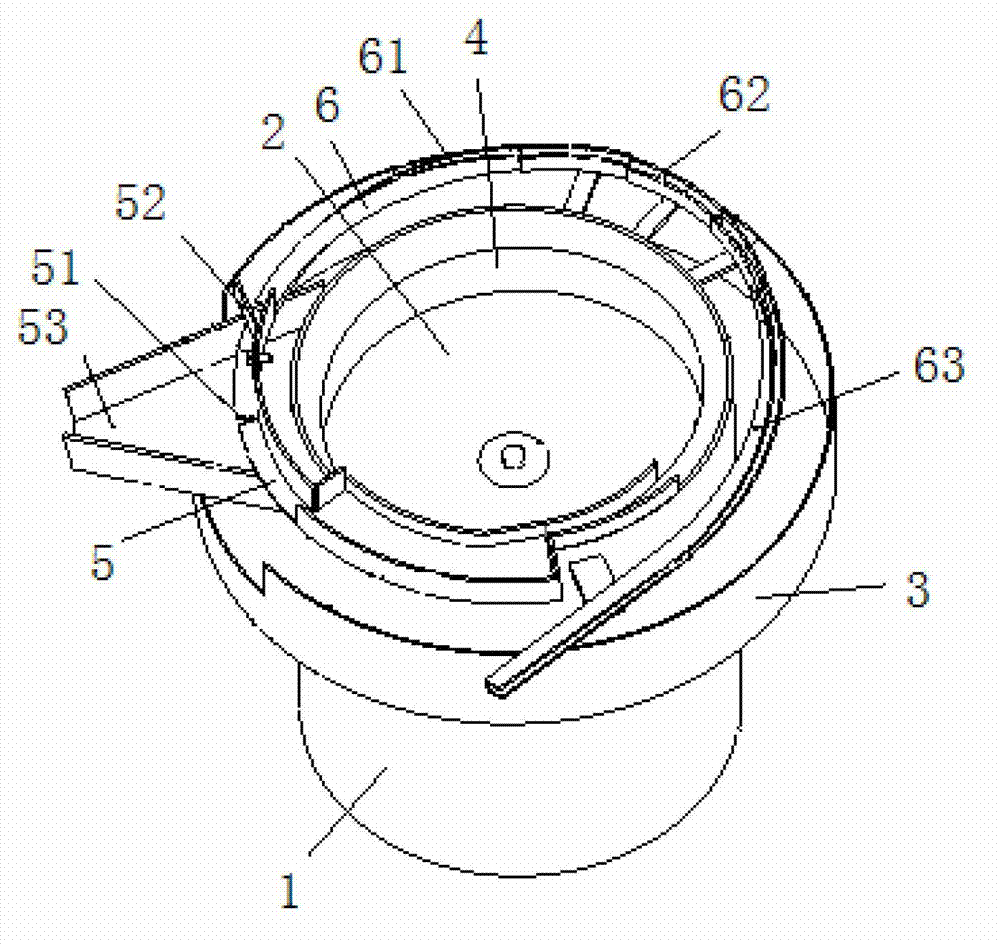

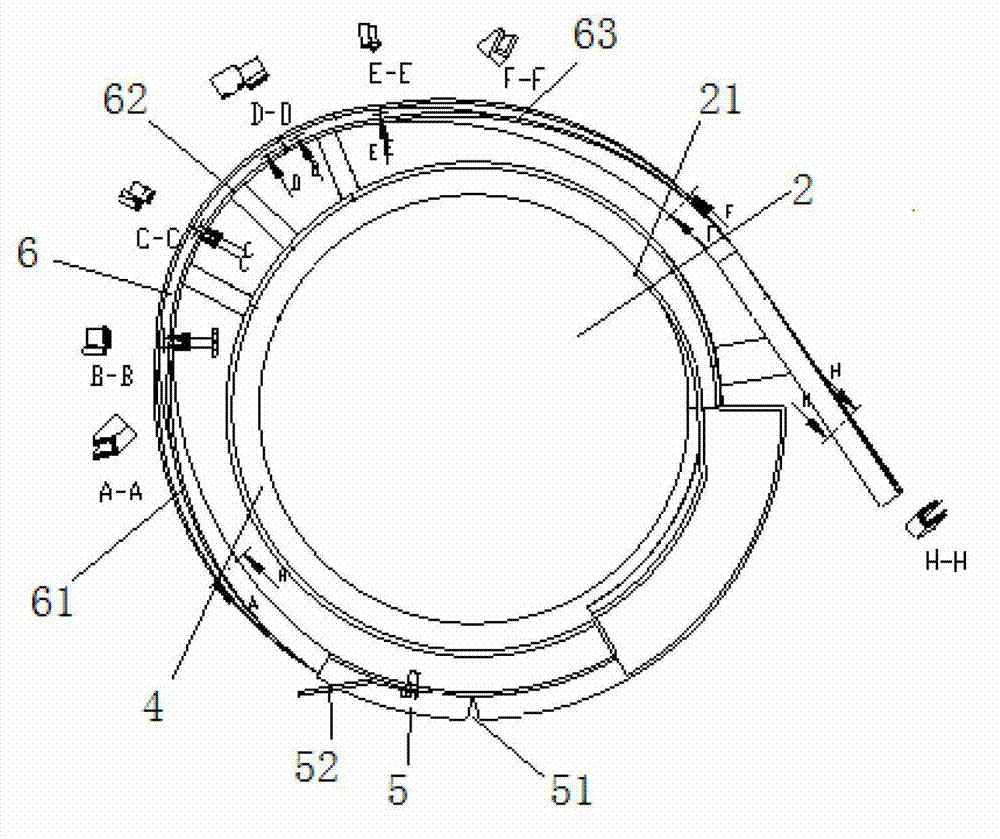

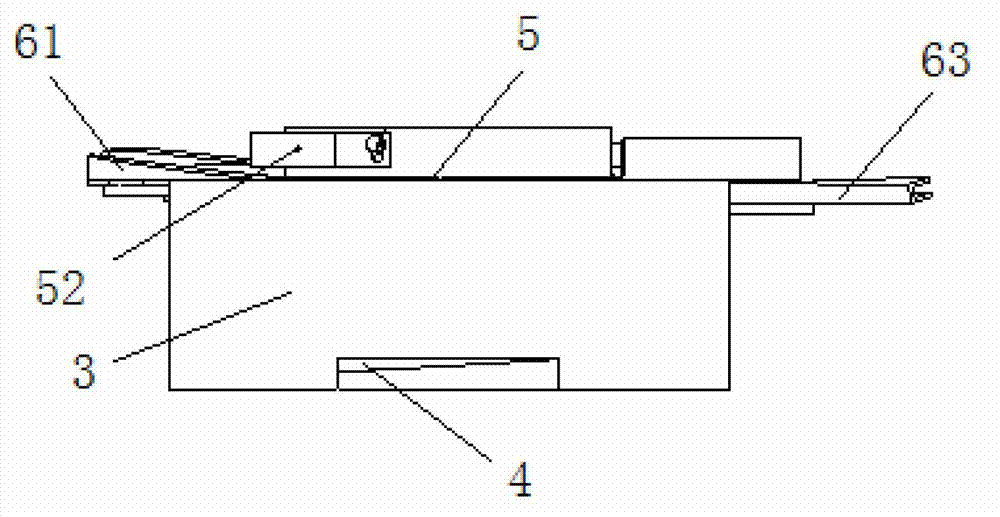

[0019] like figure 1 As shown, the present invention includes a prior art electromagnetic vibrating device 1, a damping support (not shown in the figure) is arranged at the bottom of the electromagnetic vibrating device 1, and a convex plate 2 is fixedly connected to the top of the electromagnetic vibrating device 1 , The outer edge of the chassis 21 of the convex disc 2 is provided with an outer cover 3 upwards. A spiral ascending passage is arranged between the chassis 21 of the convex disk 2 and the outer cover 3, and the spiral ascending passage is divided into a spiral conveying section 4, a sorting chute 5 and an orientation chute 6 connected in sequence. Under the vibration of the electromagnetic vibrating device 1, the corn seeds will spread from the top of the convex disk 2 to the surroundings, gradually move to the screw conveying section 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com