Itch rubbing pile for cow

A casing and column technology, which is applied in the field of itching rubbing posts for cattle, can solve the problems of itchy and shaking cattle skin, heavy workload, and ineffective anti-itching effect, so as to increase meat and milk production and prolong Longevity and obvious anti-itch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

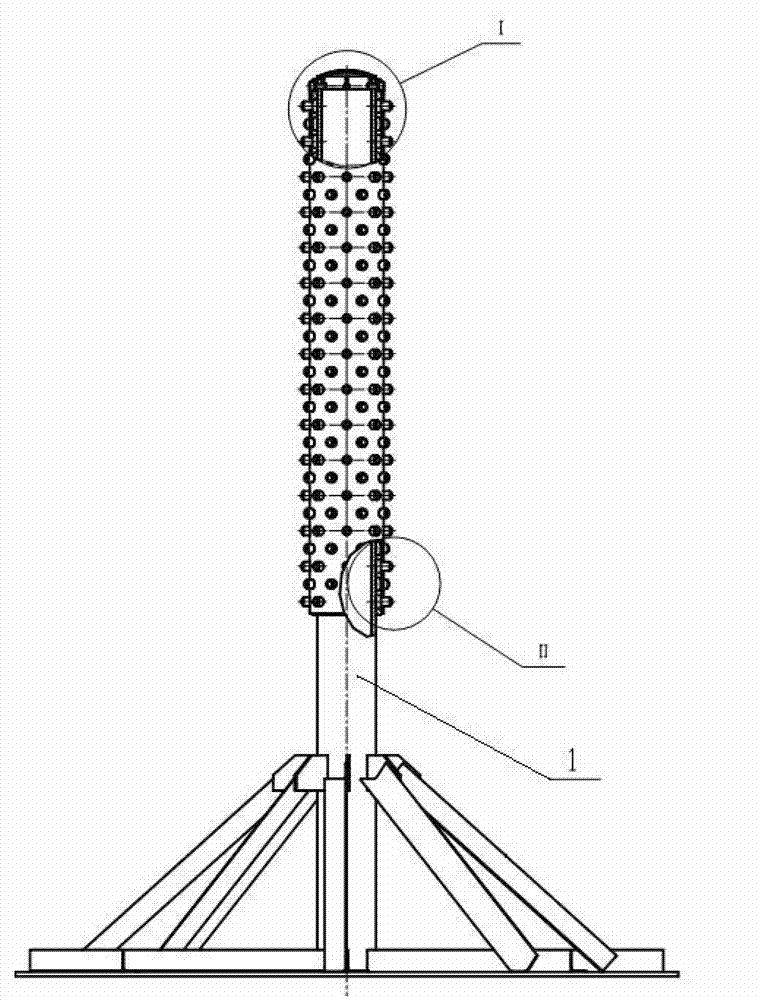

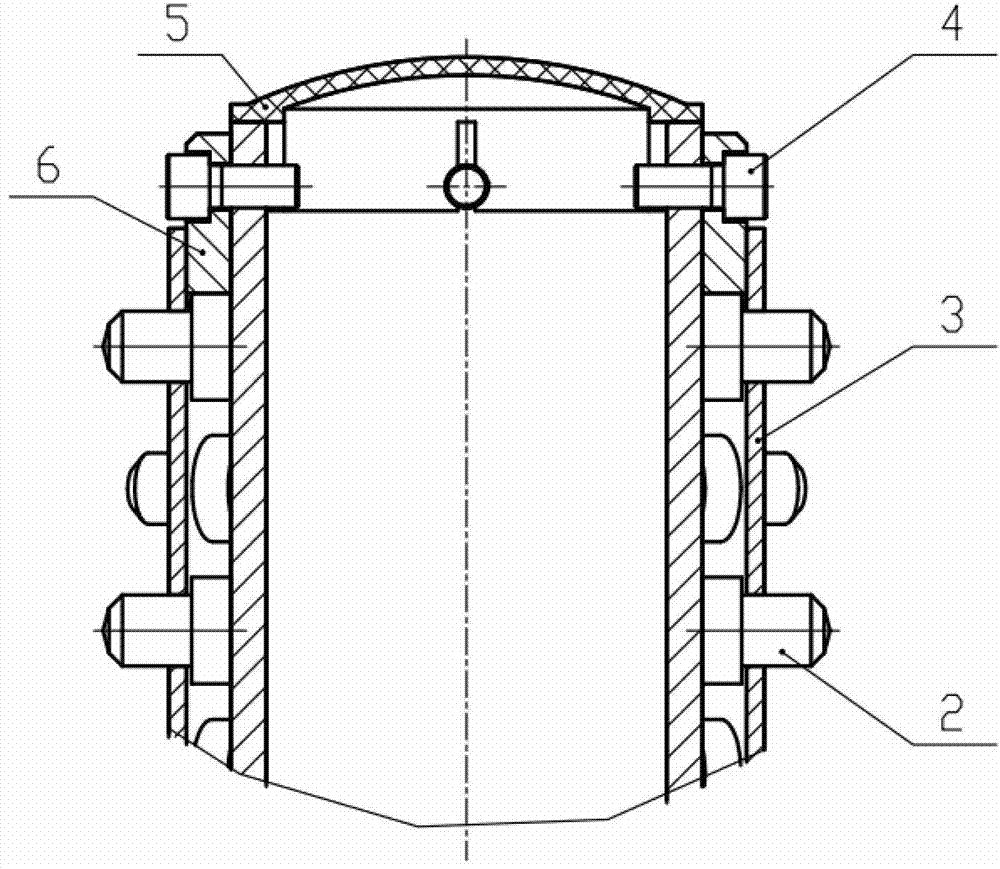

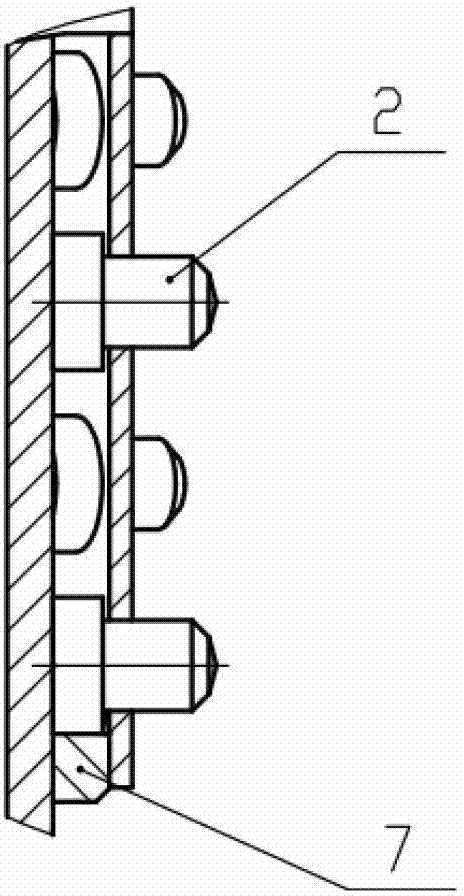

[0030] The itching post for cattle of the present invention comprises a post 1, a fixing ring 6, a casing 3, and a top cover 5. During installation, the post 1 is pre-embedded in an appropriate position in the cattle's sports field or in the barn, and the casing 3 is set on the post 1. Outside, put fixed ring 6, cover top cover 5, fix with screw 4. The outside of the rubbing pile casing 3 of the present invention is covered with nipple-shaped protruding particles 2 made of metal materials, the base and the middle part of which are cylinders, and the ends are two superimposed cones, the transition cone angle and the top cone angle All are obtuse angles. When the cow rubs on the rubbing post, the short and thick nipple-shaped protruding particles 2 made of metal can effectively remove the hardened dirt on the cow's body, and at the same time, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com