Servo central frame and application method thereof

A technology of center frame and frame, which is applied in the field of servo center frame, can solve the problems of affecting precision, processing obstacles of center frame, affecting surface roughness, etc., and achieve the effect of improving processing efficiency, ensuring reliable operation, and easily ensuring processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

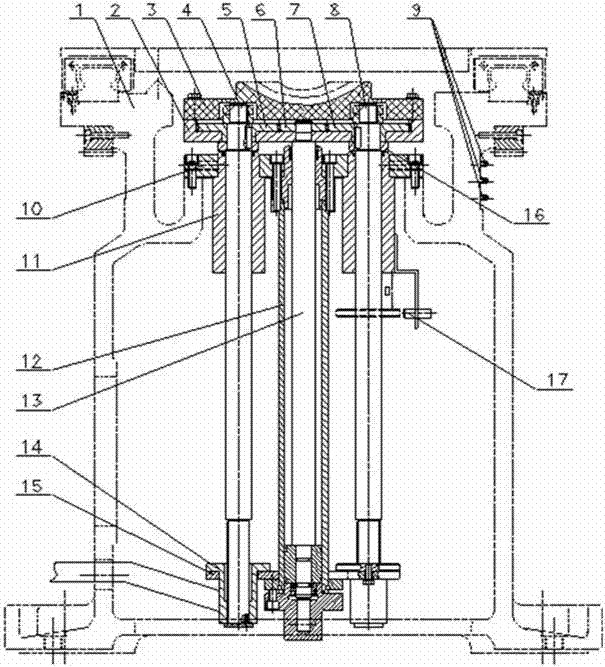

[0021] The servo steady rest proposed in this paper involves a basic realization, that is, the up and down adjustment of the steady rest.

[0022] One aspect is the matching of detection and lifting.

[0023] One guarantee, the rigidity of the steady frame after having the lifting function.

[0024] It should be understood that the servo is a closed-loop structure, but in many applications, such as many discrete components in the numerical control system are called servo components. Typical components such as servo motors are actually the execution components of the servo system.

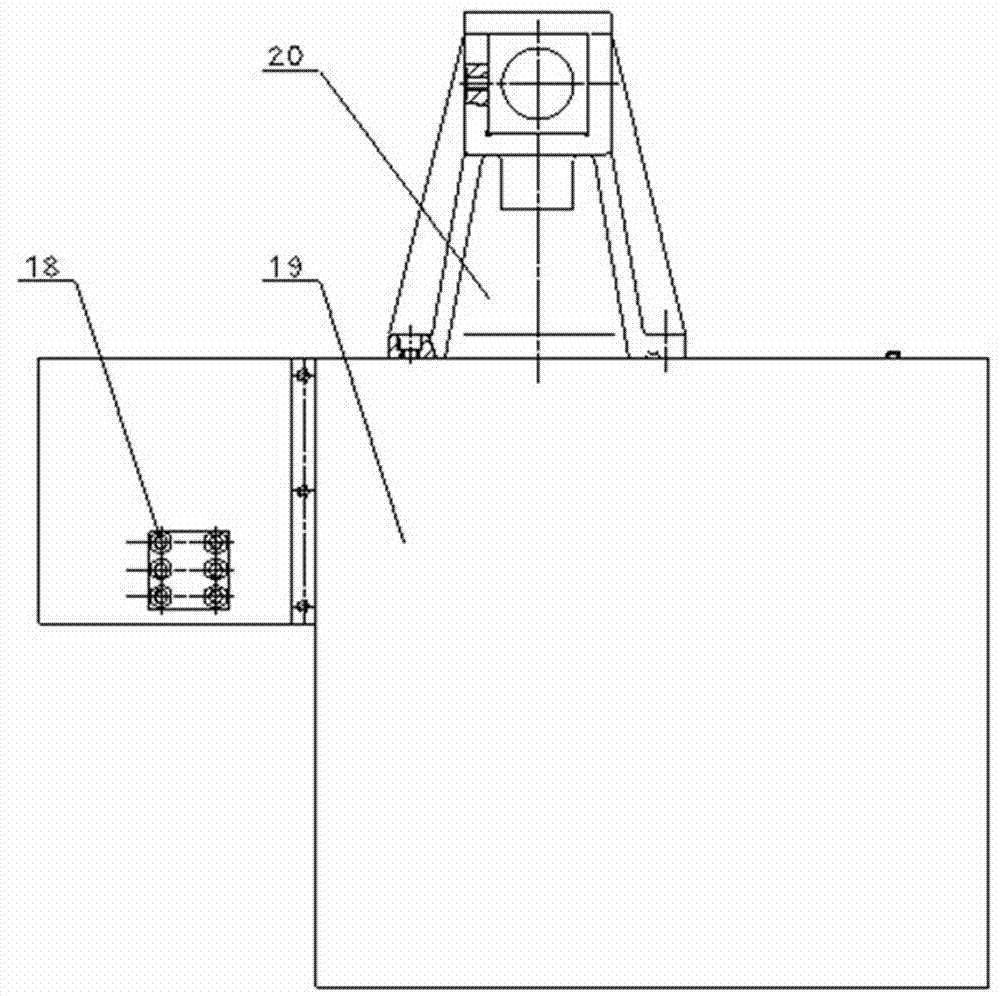

[0025] See attached figure 1 The shown servo center frame includes a frame body and a support part arranged on the frame body, and the support part is installed on the frame body through a vertical adjustment mechanism, and at least the support frame is provided with a knife for detecting A frame approach detection device to control the descent of the vertical adjustment mechanism, and reset the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com