Power tool and operation method thereof

A technology of power tools and operation methods, applied in the field of power tools, can solve the problems of time-consuming and laborious, cumbersome operation, etc., and achieve the effects of improving work efficiency, quick installation or disassembly, and preventing slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0095] The power tool involved in this embodiment is specifically a swing-type power tool, also known as a multi-function machine. But the present invention is not limited to an oscillating power tool, but may also be a rotary abrasive power tool, such as a sander or an angle grinder.

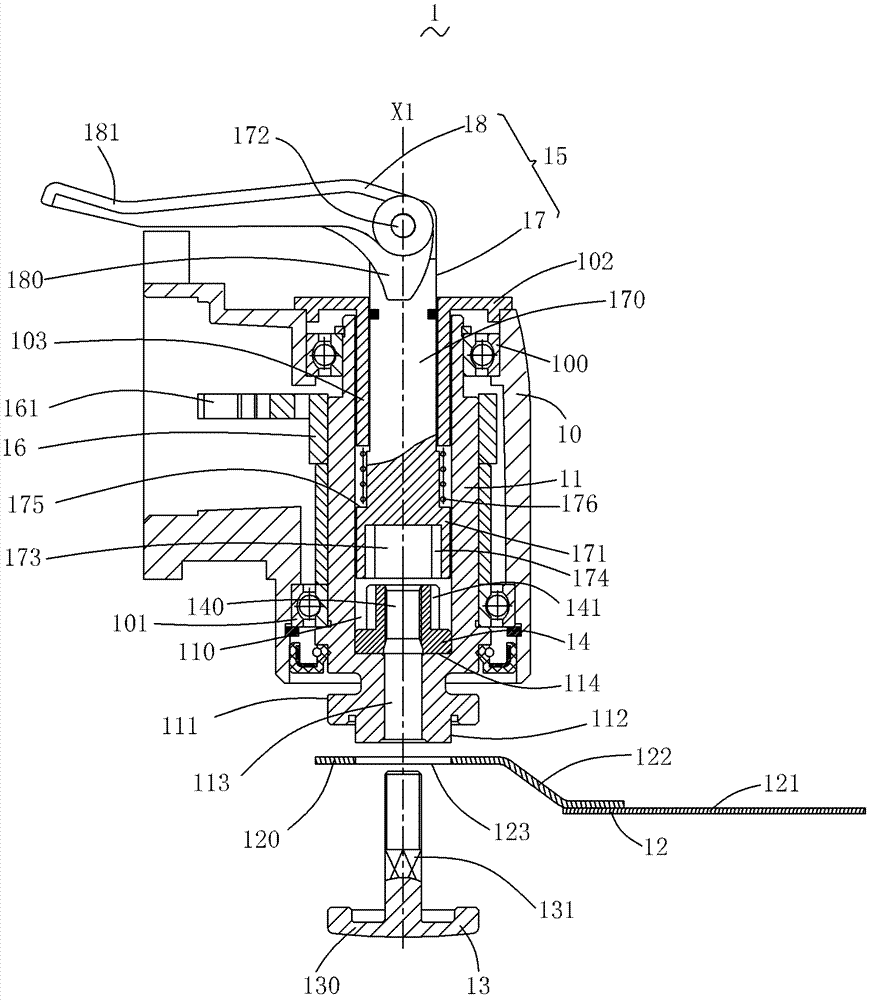

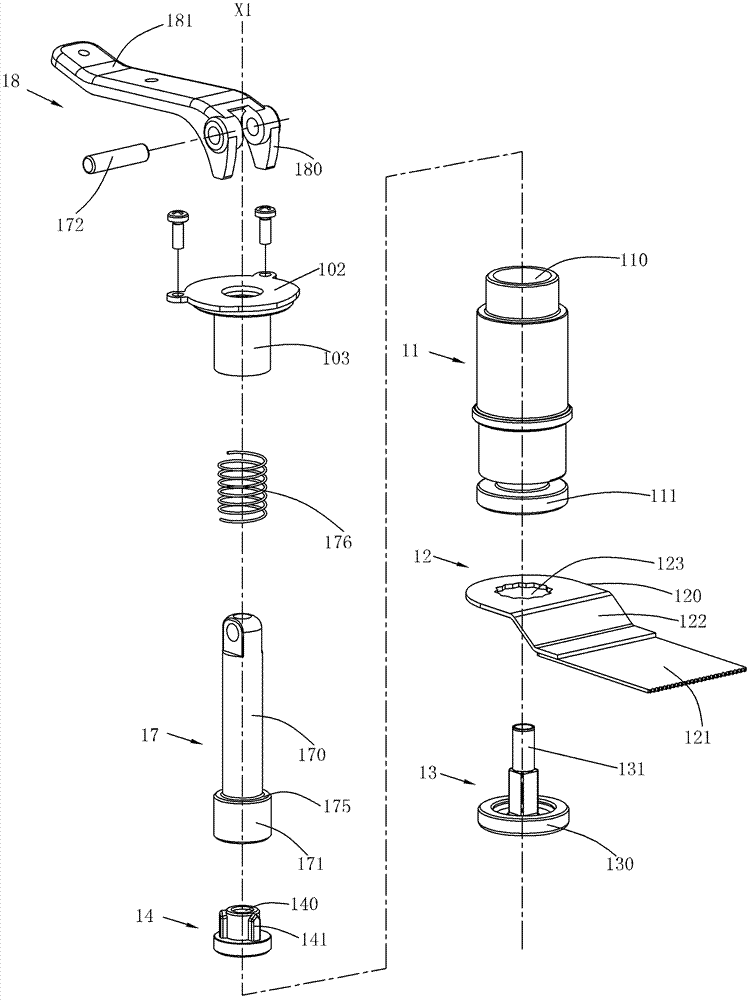

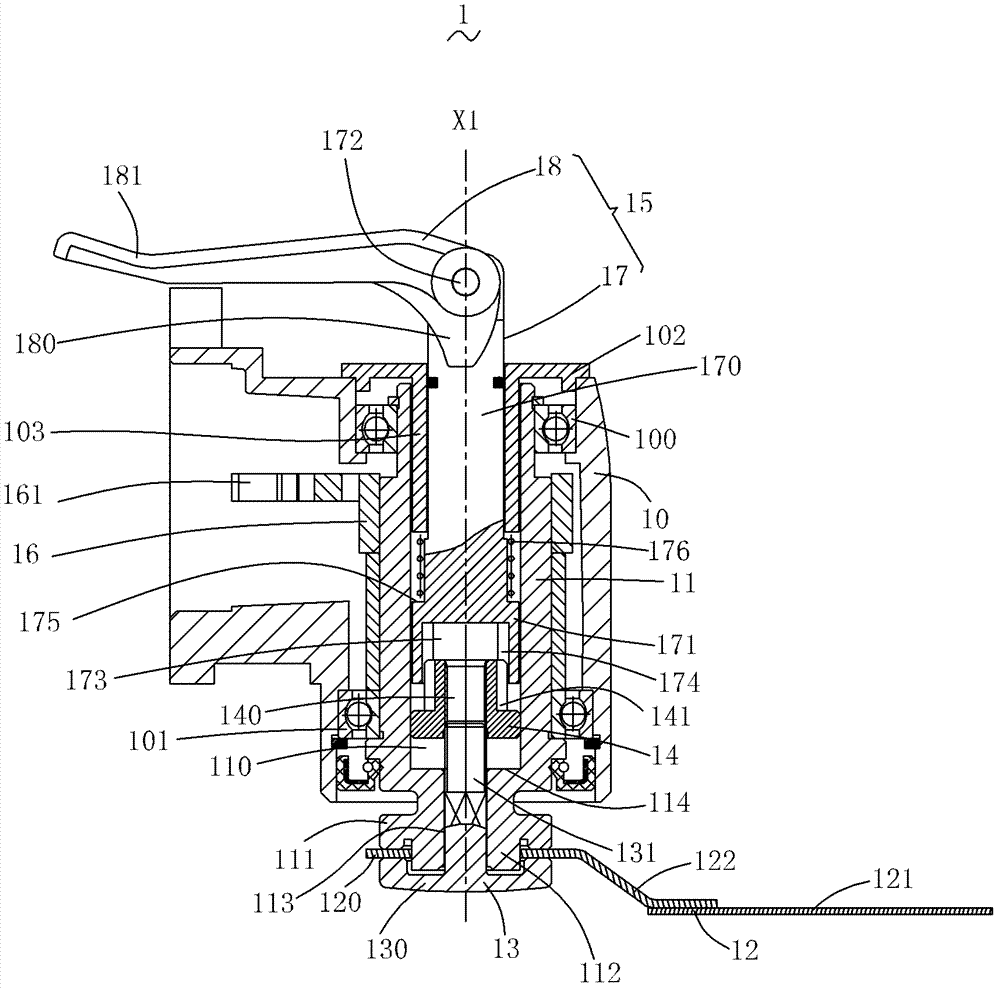

[0096] figure 1 Shown is the head area of the multifunctional machine 1 in this embodiment. The multifunctional machine 1 has a housing 10, an output shaft 11 extending from the inside of the housing 10, a working head 12 installed at the end of the output shaft 11, A locking piece 13 for fixing the working head 12 on the end of the output shaft 11 , a locking piece 14 supported in the output shaft 11 , and a driving mechanism 15 rotatable around the axis X1 of the output shaft 12 . When the driving mechanism 15 is rotated in one direction, the locking member 14 and the locking member 13 can be driven to be threaded and locked; then when the driving mechanism 15 is rotated in the opposite di...

specific Embodiment approach 2

[0123] Such as Figure 7 to Figure 10 As shown, the second embodiment of the present invention discloses an oscillating power tool, that is, a multi-function machine 2, the multi-function machine 2 includes a housing 20, an output shaft 21 installed in the housing 20, and an output shaft 21 inserted into the The locking piece 22, the working head 23 clamped between the locking piece 22 and the output shaft 21, the locking piece 24 accommodated in the output shaft 21 and used to lock the locking piece 22, and the locking piece 24 for driving A drive mechanism 25 rotating around the axis X2 of the output shaft 21 .

[0124] Such as Figure 7 and Figure 8 As shown, compared with the multifunction machine 1 in the first embodiment, the drive mechanism 25 has a different structure. The driving mechanism 25 specifically includes an operating assembly 26 and a driving assembly 27 , and the operating assembly 26 is operable to drive the driving assembly 27 to rotate. Wherein, the...

specific Embodiment approach 3

[0129] Combine below Figure 11 Briefly introduce the third embodiment of the present invention, specifically a multifunctional machine 3, including a housing 30, an output shaft 31 installed in the housing 30, a locking piece 32 inserted into the output shaft 31, and a locking piece clamped on the locking piece. 32 and the working head 33 between the output shaft 31, the locking member 34 accommodated in the output shaft 31 and used to lock the locking member 32, and the driving mechanism for driving the locking member 34 to rotate around the axis X3 of the output shaft 31 35. Wherein, the driving mechanism 35 includes an operating assembly 350 and a driving assembly 351 , and the operating assembly 350 is operable to drive the driving assembly 351 to rotate. Compared with the multifunctional machine 2 in the second embodiment, the only difference lies in its locking member 34 .

[0130] The locking member 34 is axially non-movably installed in the output shaft 31 , so as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com