Maintenance support

A technology for maintenance parts and support frames, applied in the field of mechanical tooling, can solve the problems of reduced maintenance efficiency, out-of-control parts falling off, fixed positioning, etc., and achieve the effects of improving maintenance efficiency, facilitating widespread use, and facilitating maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

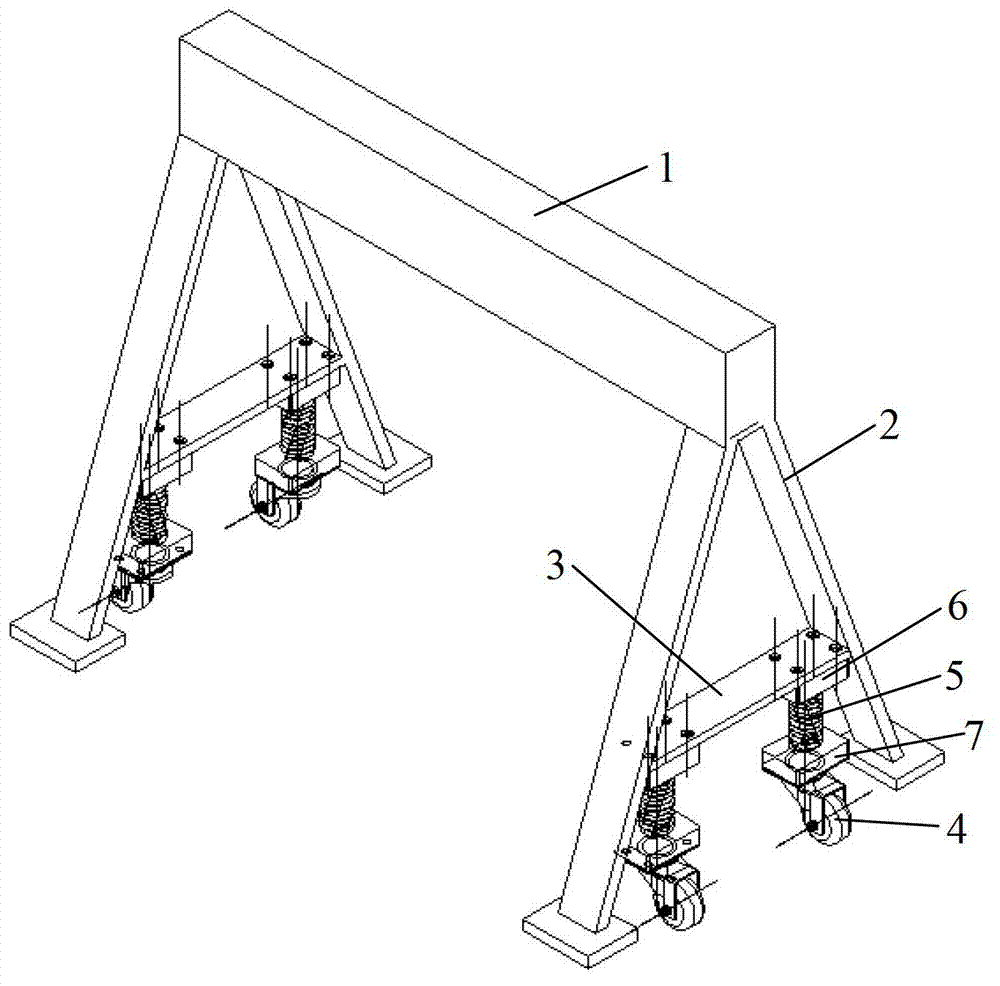

[0014] figure 1 A schematic diagram of the structure of the maintenance bracket of this embodiment is shown. Referring to the diagram, the maintenance bracket of this embodiment includes two parts, namely a support frame and a walking mechanism. The support frame is used to fix the repaired parts and realize the fixation of the repaired parts Positioning is convenient for maintenance personnel to maintain the repaired parts; the running mechanism is arranged at the bottom of the support frame to assist the movement of the support frame, but during the maintenance process of the repaired parts, the positioning of the running mechanism is still to ensure that the support frame and its The parts to be repaired on the machine are all fixed and positioned, so that the maintenance bracket can absolutely fix and position the parts to be repaired and facilitate the maintenance and use of the parts to be repaired at different stations.

[0015] Specifically, the support frame includes:...

Embodiment 2

[0021] The structure of the maintenance bracket provided by this embodiment is similar to that of the first embodiment, the difference lies in the setting of the running mechanism. In the first embodiment, when the roller 4 is set on the positioning plate 3, the spring guide pin 5 is used to realize the supporting frame positioning and walking, in this embodiment, by setting the locking buckle on the roller 4 to replace the spring guide pin structure, when the maintenance bracket needs to move and walk, the locking buckle on the roller 4 can be unlocked, so that the roller 4 touches the ground , make the beam support beam 2 leave the ground, and move the maintenance bracket freely through the action of the roller 4; Positioning of the supporting frame. The structure of the locking buckle is relatively common in the prior art, and will not be further described here.

[0022] The serial numbers of the above embodiments of the present invention are for description only, and do n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com