Vegetable cutting device

A vegetable cutting device and vegetable technology, applied in metal processing and other directions, can solve problems such as shredding or irregular shape of slices, and achieve the effect of simplifying operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

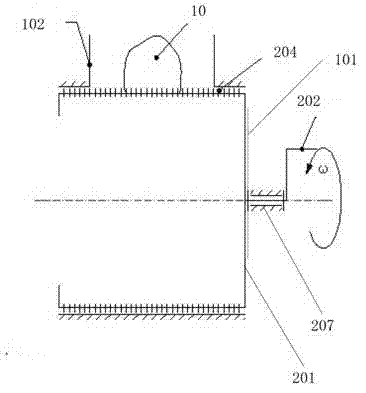

[0030] Such as figure 1 As shown, the vegetable cutting device in this embodiment includes: an outer cylinder 101 and a knife cylinder 201 , and the knife cylinder 201 is arranged inside the outer cylinder 101 and can rotate.

[0031] Such as figure 2 As shown, the outer cylinder 101 includes: a back plate 105 for closing one end of the outer cylinder 101, and a rotating shaft support hole 106 is arranged on the back plate 105; a material inlet 102 is arranged on the wall of the outer cylinder 101 for making the The vegetables put in contact with the knife cylinder 201 .

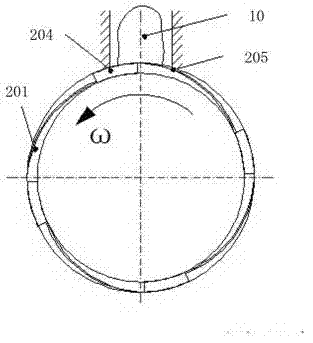

[0032] Such as image 3 with Figure 4 As shown, the cutter cylinder 201 includes: a support plate 206, which is used to close one end of the cutter cylinder 201, and the center of the support plate is provided with a rotating shaft fixing hole 203; a rotating shaft 207 is arranged along the axis of the cutter cylinder 201, and passes through the rotating shaft The fixing hole 203 is fixedly connected w...

Embodiment 2

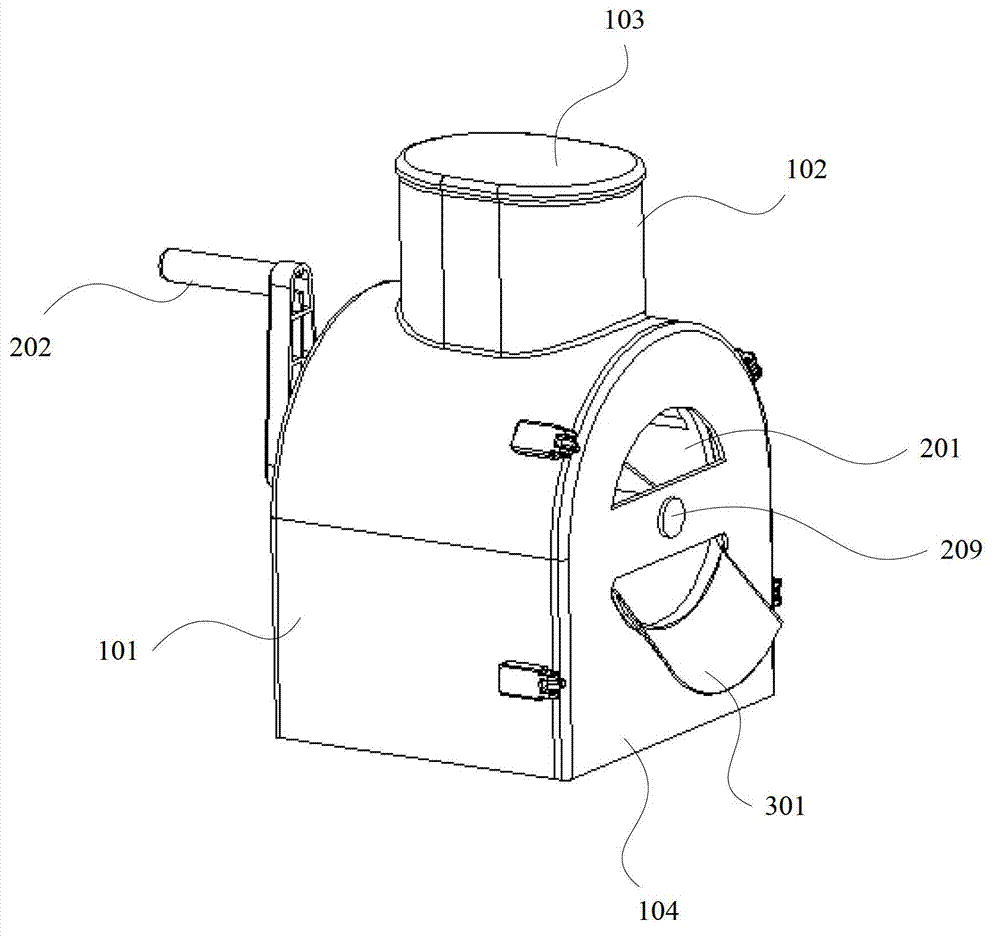

[0035] Such as Figure 5 As shown, the vegetable cutting device in this embodiment includes: an outer cylinder 101 , a knife cylinder 201 and a pressing cover 103 , and the knife cylinder 201 is arranged inside the outer cylinder 101 and can rotate. The pressing cover 103 is used for inserting into the feeding port to press the vegetables to the knife barrel 201 . The outer cylinder 101 includes: a back plate, which is used to close one end of the outer cylinder 101, and a rotating shaft support hole is arranged on the back plate; a material inlet 102, which is arranged on the upper end of the wall of the outer cylinder 101, is used to make the put vegetables and the knife Cartridge 201 contacts. Knife cylinder 201 comprises: support plate, is used for closing one end of knife cylinder 201, and the center of support plate is provided with rotating shaft fixing hole; Rotating shaft 207, is arranged along the axis of knife cylinder 201; The cutter cylinder 201 is fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com