Elevator rolling guide shoe with brake function

A technology for rolling guide shoes and elevators, applied in the directions of transportation, packaging, elevators, etc., can solve the problems of undiscovered emergency braking of elevator car, lack of guide wheel stop mechanism, mutual interference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

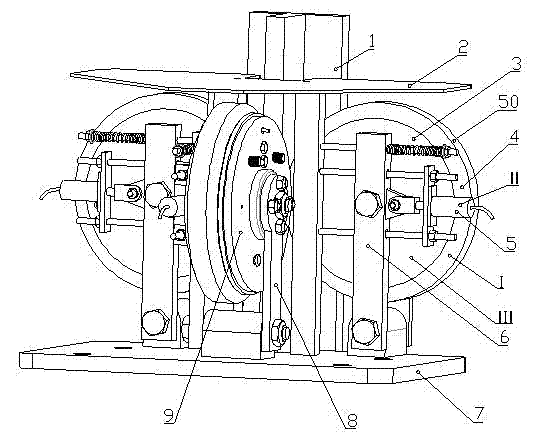

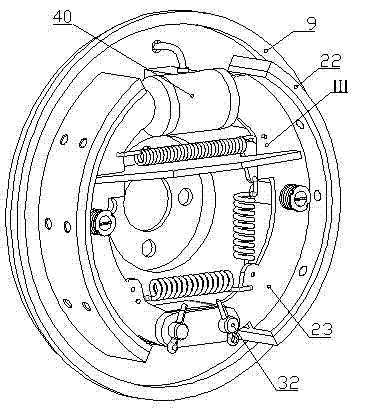

[0030] see Figure 1~Figure 3, the elevator rolling guide shoe with braking function, including: rolling guide wheel mechanism (I), hydraulic actuator (II) and stop mechanism (III), characterized in that: the rolling guide wheel mechanism (I) The three guide wheels (50) are closely attached to the three working surfaces of the T-shaped guide rail (1), the hydraulic actuator is connected with each guide wheel (50) of the rolling guide wheel mechanism, and the stop mechanism ( Ⅲ) Integrated inside the guide wheel (50); when the elevator stalls, whether it is ascending or descending, the stop mechanism (Ⅲ) can stop the guide wheel (50) from rotating, and cooperate with the pressing force provided by the hydraulic actuator , so that the guide wheel (50) hugs the guide rail (1) to realize emergency braking.

Embodiment 2

[0032] see Figure 1~Figure 8 , the present embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0033] The elevator rolling guide shoe with braking function is characterized in that: the rolling guide wheel mechanism (I) includes a brake drum (3), a wear-resistant rubber layer (4), a guide shoe base (7), The main swing rod (6), the secondary swing rod (8), the limit spring (10), and the connecting long rod (20), wherein the outer layer of the brake drum (3) is inlaid with a wear-resistant rubber layer (4) to form Guide wheel (50), main and minor fork (6,8) lower ends are all hinged with guide shoe base (7), two fork ( A rotating shaft (16) is installed between 6 and 8), the brake drum (3) is installed on the rotating shaft (16), and the first connecting rod (20) passes through the main swing rod on the side of the guide wheel (50) (6) After connecting with the fixed vertical column of the guide shoe base (7), the limit spring (10) is ...

Embodiment 3

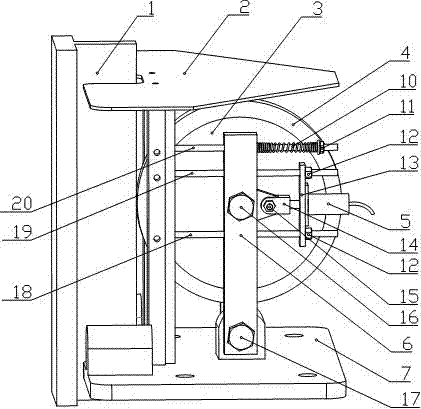

[0037] The specific structure of this embodiment is described in detail as follows:

[0038] figure 2 Shown is the three-dimensional structure diagram of the elevator guide shoe and the guide wheel, and the two side guide wheels have the same working structure. Refer to the following figure 2 , the general structure of the rolling guide wheel mechanism (I) in the present invention will be described.

[0039] The rolling guide wheel mechanism includes brake drum (3), wear-resistant rubber layer (4), guide shoe base (7), primary and secondary swing bars (6, 8), limit spring (10), connecting rod (20 ). Among them, the guide shoe base (7) is fixed to the elevator car, the brake drum (3) rotates around the guide wheel rotation axis (16), and can swing around the swing lever rotation axis (17) along with the main swing lever (6). The brake drum (3) is covered with wear-resistant rubber (4) and is in contact with the front of the T-shaped guide rail (1). The first connecting lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com