Railway ballast distribution reshaping and curing device

A technology for railways and cleaning devices, applied in the directions of roads, cleaning methods, tracks, etc., can solve the problems of poor passing ability, poor operation visibility, and poor operation and operation vision of turnouts, and achieve beautiful appearance, good dynamic performance, and good operation function. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

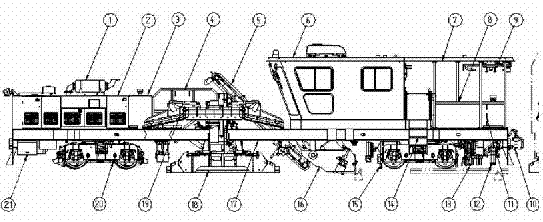

[0015] Such as figure 1 As shown, the railway ballast shaping and maintenance device includes a single driver's cab 6, a power transmission system 1, a power room 2 and an equipment rack 17, and is characterized in that the device also includes two two-axis steering gears 15, 20, and a side plow device 19. Middle plow device 18, pillow surface cleaning device 16, fine cleaning device 12 and rail side vertical cleaning device 13, single cab 6 is set in the middle of equipment rack 17, power transmission system 1 and power room 2 are set in equipment rack 17 The front part of the machine ensures the power required for the operation and operation of the whole machine; the single cab 6 is equipped with front and rear operating consoles, which can realize the requirements of two-way ballasting and shaping operations and two-way high-speed travel, and has a good view; two two-axis steering gears have a total of four The shaft is set at the lower part of the equipment frame to meet t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com