Vibration-free anti-slip lane and construction method thereof

A construction method and slideway technology, applied in the directions of roads, roads, pavement details, etc., can solve the problems of poor comfort, durability and aesthetics of cement sill lanes, poor damping of anti-skid tile lanes, and poor durability of epoxy sand-spraying lanes. Achieving the effect of beautiful and bright patterns, elimination of splashing and water mist, and easy promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with the accompanying drawings.

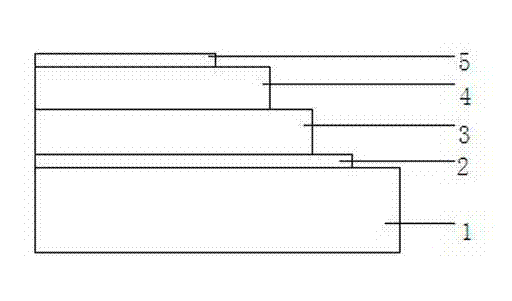

[0065]As shown in the accompanying drawings: a non-vibration anti-skid lane, the lane is composed of a basic plain layer 1, an interface sealing layer 2, a pressure-resistant layer 3, an anti-skid layer 4 and a surface maintenance layer 5 from bottom to top, and the interface sealing Layer 2 has a thickness of 0.1mm, the pressure-resistant layer 3 has a thickness of 3mm, the anti-slip layer 4 has a thickness of 3mm, and the surface maintenance layer 5 has a thickness of 0.1mm. The interface sealing layer 2 is formed by placing a permeable microporous carbonized interface sealant directly on the concrete surface for sealing, and the anti-pressure layer 3 is formed by applying a layer of polygonal hardness mineral bone on the interface sealing layer 2 material and water-based modified resin, the anti-slip layer 4 is formed by spraying polygonal hardness mineral aggregate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com