Land leveler and scarifier thereof

A technology of ripper and ripper teeth, which is used in devices for loosening soil, earthmoving machines/shovels, agricultural machinery and implements, etc., can solve the problems of the number of ripper teeth and the unadjustable teeth position, and improve the operation efficiency. , strong adaptability, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

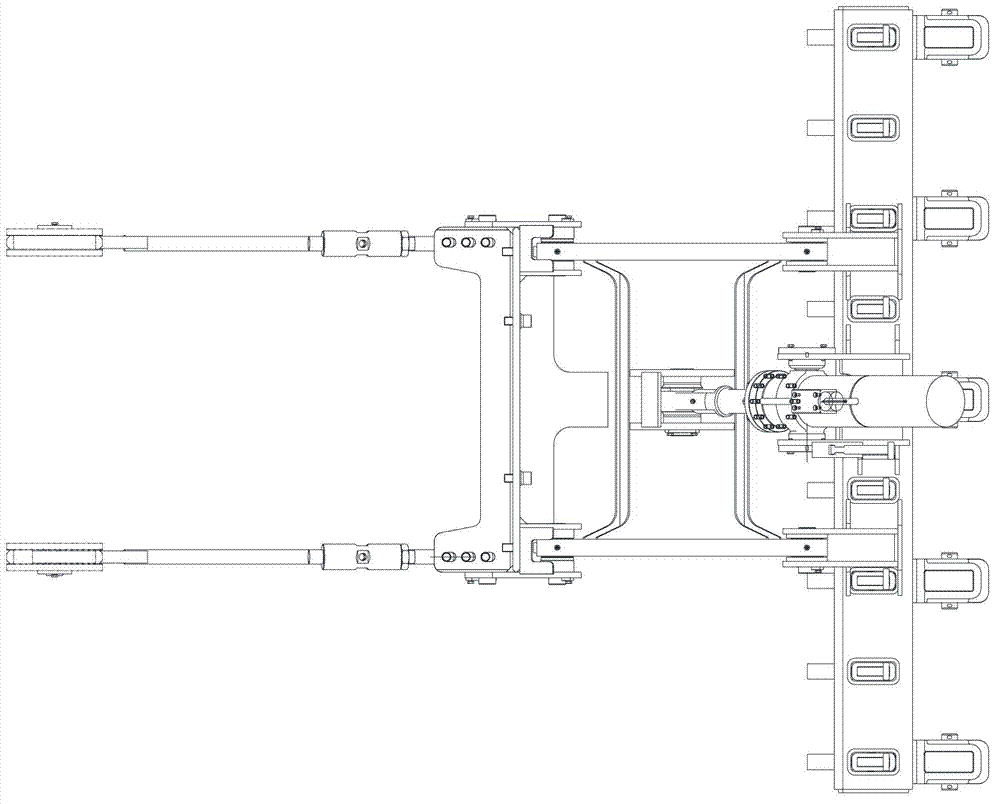

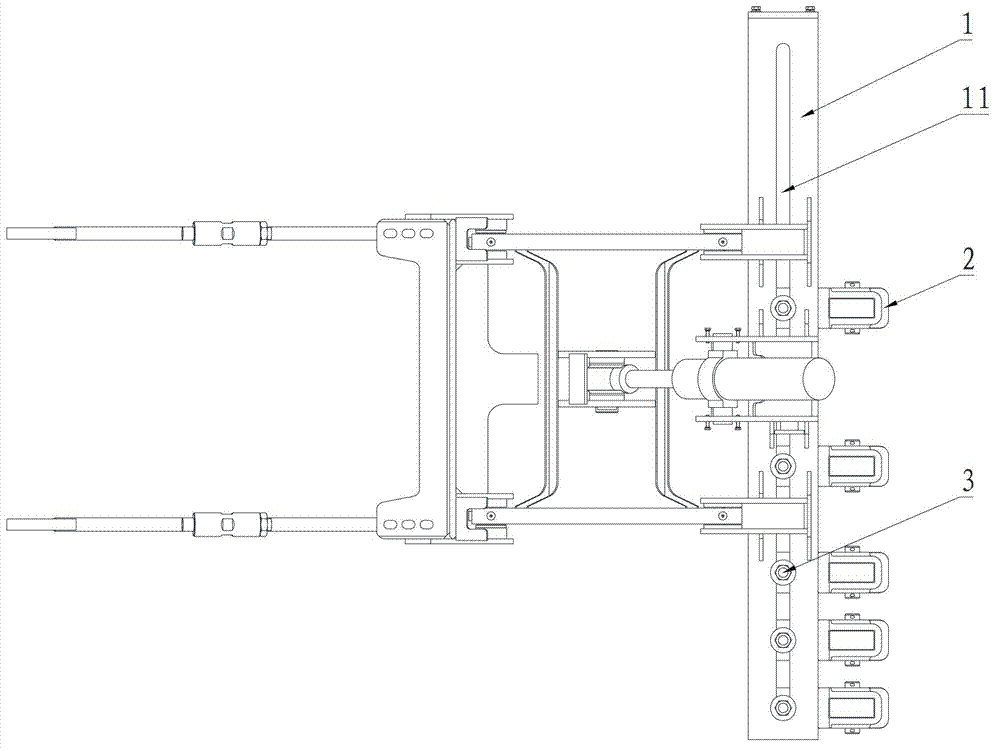

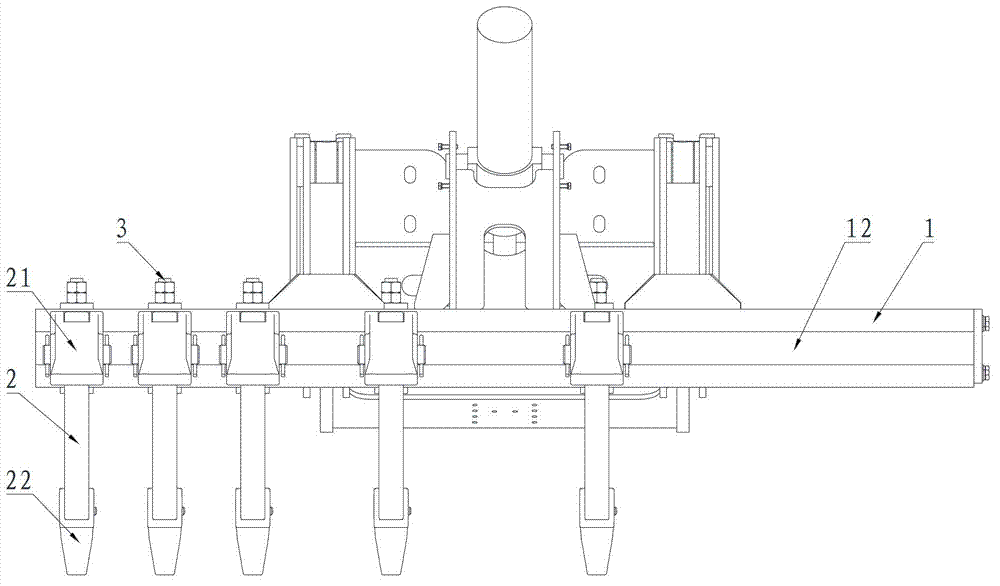

[0029] Figure 2 to Figure 6 It is the related drawings of the ripper described in the embodiment of the present invention. As shown in the figure, the ripper includes a tooth frame 1, a ripper tooth 2, a limit device, a bolt 3 and a wear-resistant sleeve 13. The tooth frame 1 It is a hollow beam structure with an opening 12, and its section is roughly C-shaped. Two vertically opposite strip holes 11 are arranged on the hollow beam structure along its axial direction; the loosening tooth 2 includes a mounting part 21 and a loosening part 22, the end of the mounting part 21 is fitted in the hollow structure of the rack 1 and can move along its axial direction, the other end of the mounting part 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com