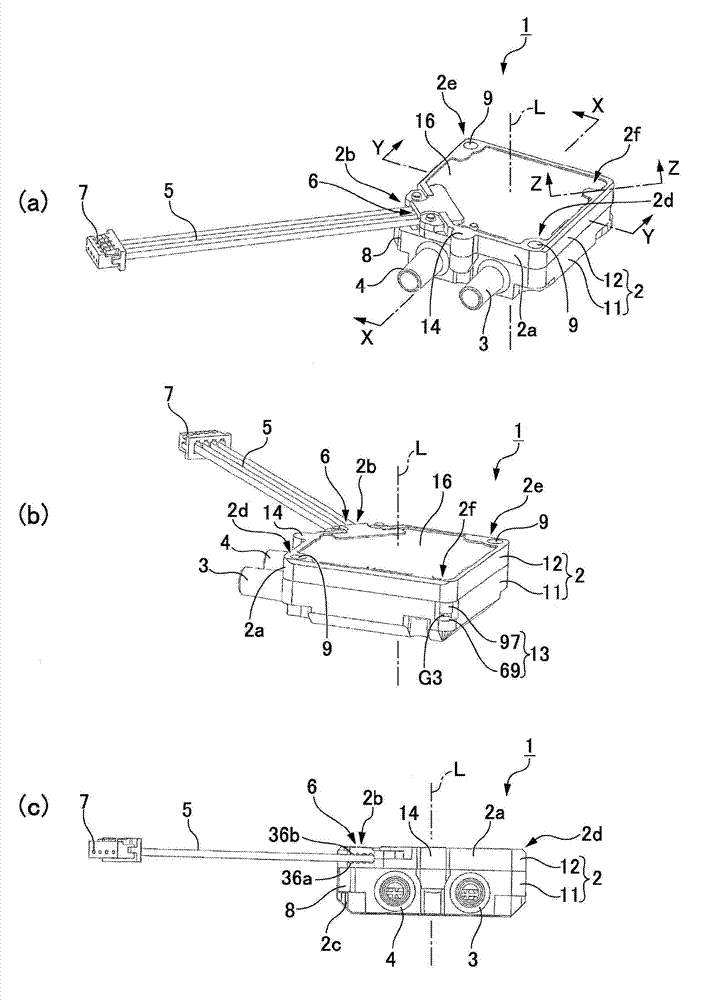

Pump device

A technology of pump device and pump chamber, which is applied in the direction of pump device, pump, and parts of pumping device for elastic fluid, etc., can solve problems such as weakening effect, and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

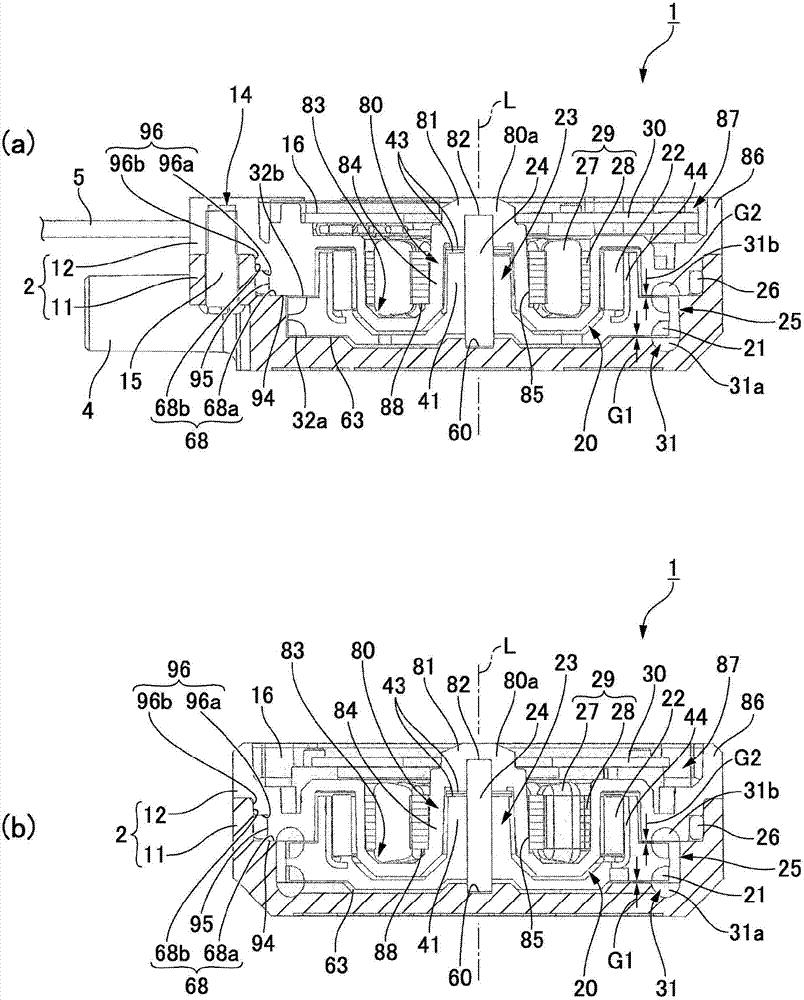

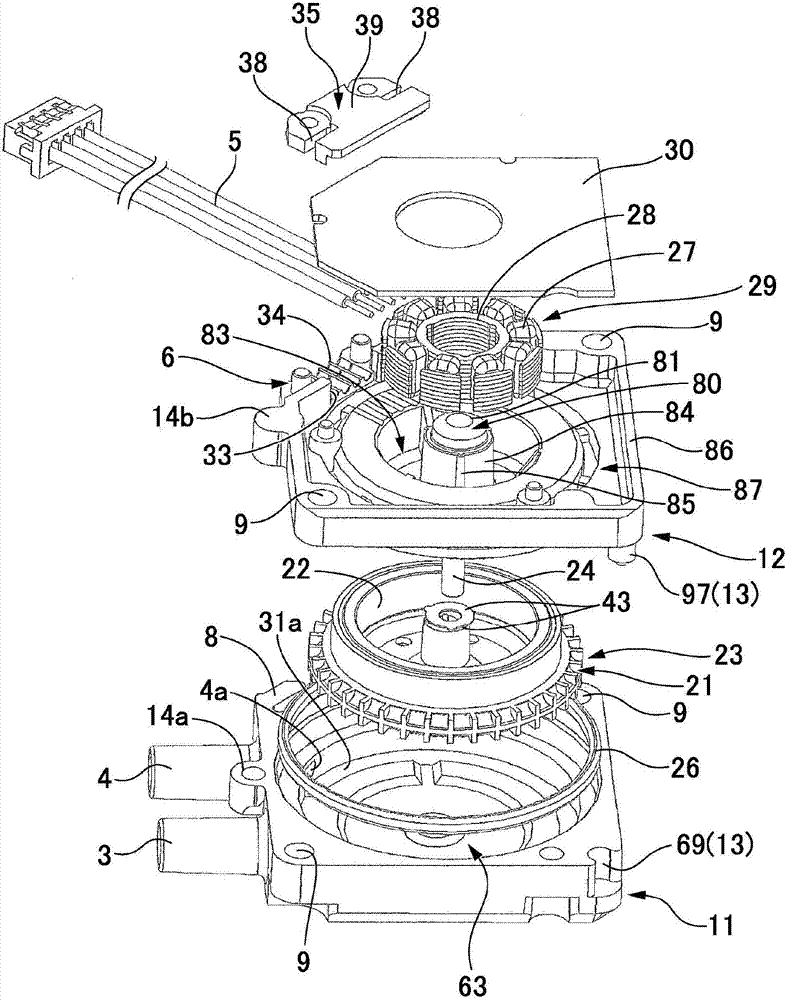

Method used

Image

Examples

other Embodiment approach

[0110]In the above example, the front end surface 97a of the anti-rotation protrusion 97 is at the same position as the annular lower end surface 94 of the annular protruding portion 91 in the axis L direction, but it may be located at a lower position than the annular lower end surface 94 in the axis L direction. The lower end face 94 is closer to the side of the lower shell 11 . In this case, the anti-rotation protrusion 97 can be inserted into the anti-rotation recess 69 before the annular protruding portion 91 of the upper case 12 is inserted into the annular step portion 68 of the lower case 11. Relative rotation of the upper case 12 and the lower case 11 is prevented. In addition, if the dimension in the axial direction is sufficient, the front end surface 97a of the anti-rotation protrusion 97 may be formed to be located on the side of the upper case 12 than the annular lower end surface 94 of the annular protrusion 91 in the direction of the axis L. Location. That is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com