Bogie steering resistance moment measurement test bench

A technology of slewing resistance and bogies, which is applied in the field of rail vehicles, can solve the problems of complex operation, inability to measure the slewing resistance torque of bogies, and low test accuracy, and achieve the effect of large slewing angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The specific structure of the patent of the present invention will be described in further detail below in conjunction with the accompanying drawings.

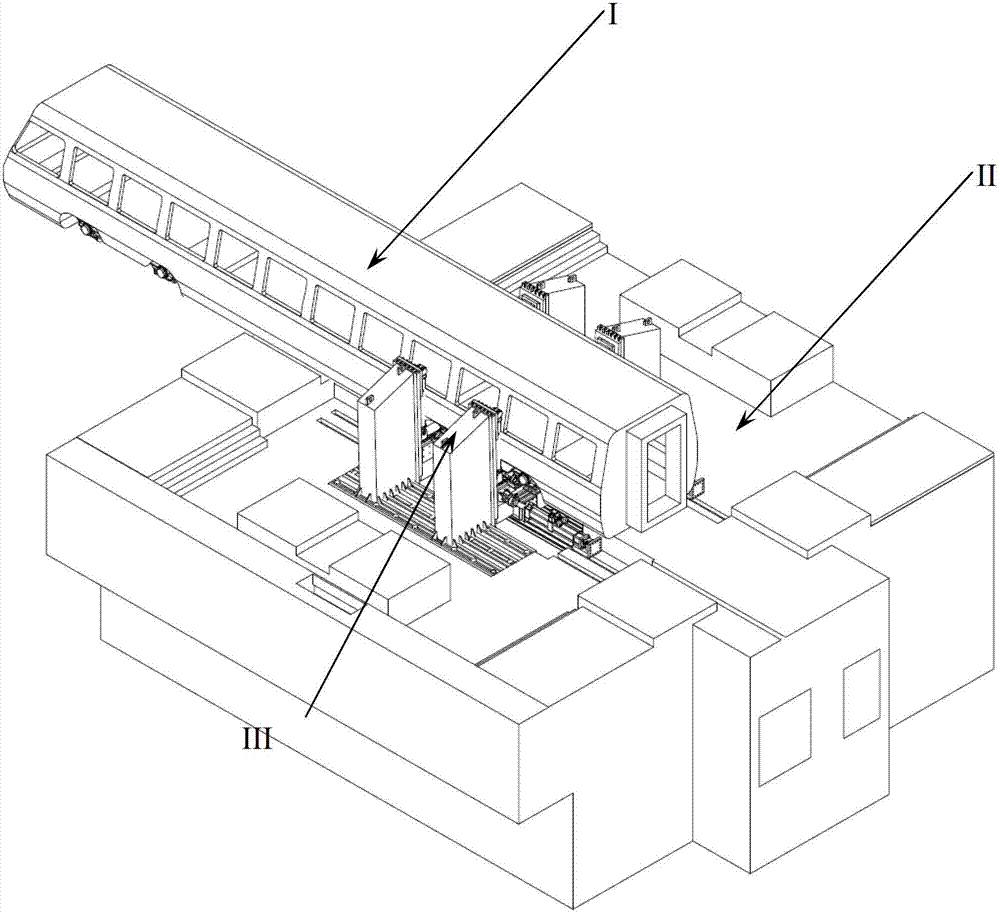

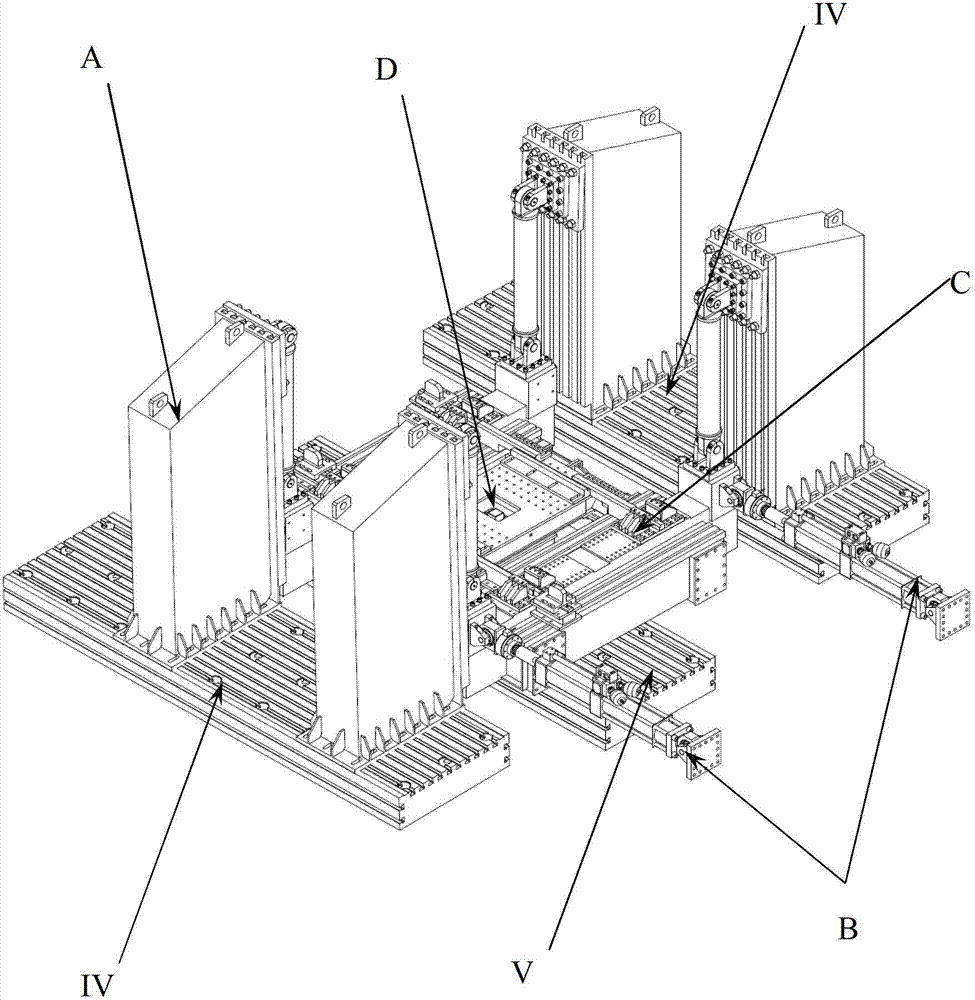

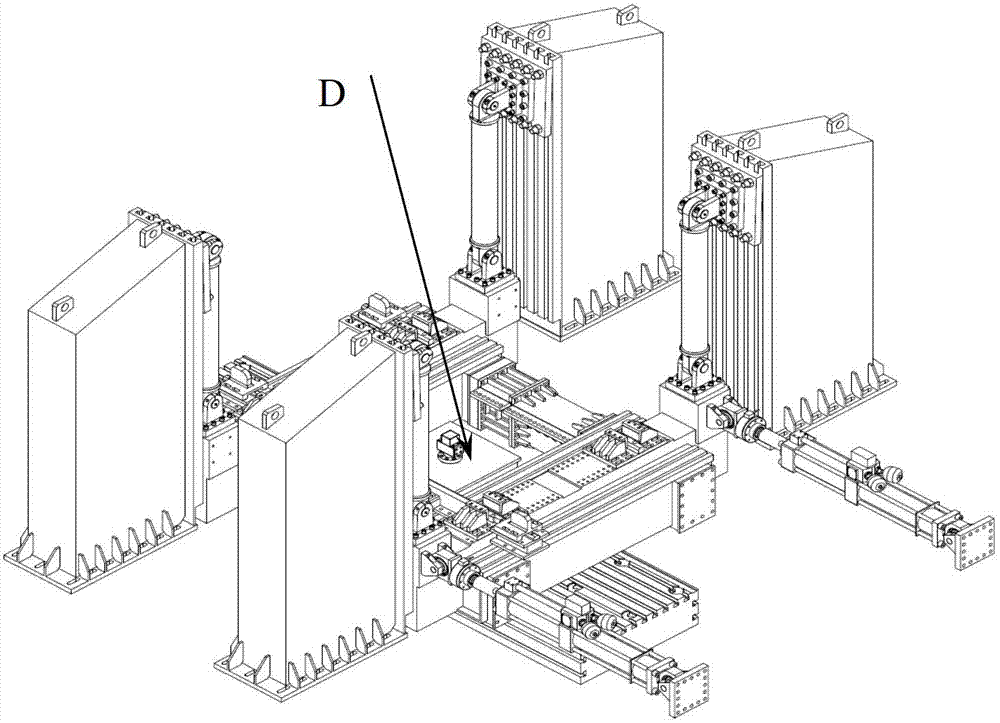

[0056] refer to Figure 1-3 , the bogie rotary resistance torque measurement test bench of the present invention is mainly composed of an auxiliary hoisting mechanism A, an electro-hydraulic servo system B, a rotary resistance torque measurement platform C, a rotary shaft and a lateral positioning mechanism assembly D, and a lower fixed platform V , which is characterized in that four sets of auxiliary hoisting mechanisms A lift the rotary resistance torque measurement platform C, and one end of the auxiliary hoisting mechanism A fixes the support r in the T-shaped groove of the test bench reaction seat fixing platform IV through T-shaped bolts , at the other end, the hinged seat of the hoisting rod t is bolted to the measuring platform C of the rotary resistance torque; the lower hinge points of the two longitudinal ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com