Method and device for measuring gelling time of gel

A technology of gel formation time and measurement method, which is applied in the field of profile control and water plugging experiments in oilfields, can solve the problems of gel structure damage, large deviation of measurement results, inability to measure some systems, etc., and achieves good repeatability and accurate gel formation time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

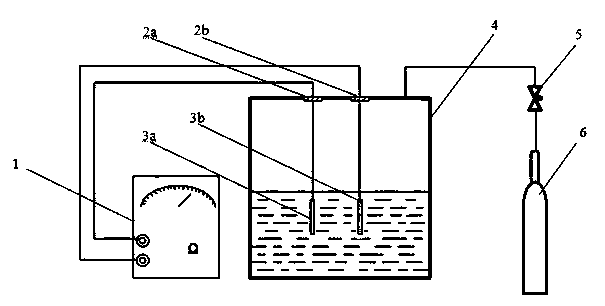

Method used

Image

Examples

Embodiment 1

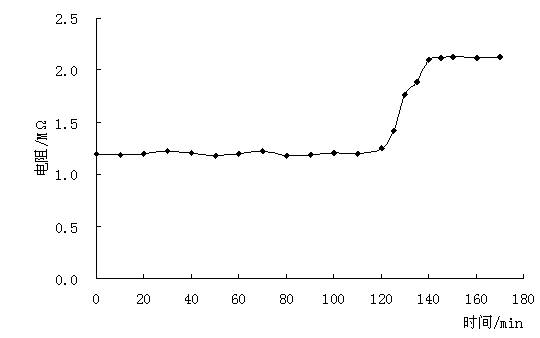

[0017] Example 1 Add an inorganic gel system composed of 8% water glass (modulus 3.14) and 0.3% urea into the reaction kettle 4, and immerse the electrode in the middle of the solution, and inject it into the reaction kettle 4 through the booster device 6 Inflate nitrogen to 15MPa, then keep the temperature to 90°C, and keep the pressure inside the reactor constant during the heating process. Start the multimeter 1 to measure the change of system resistance. See the measurement results figure 2 . according to figure 2 From the measurement results, it can be seen that the resistance of the system does not change much in the first 120 minutes, and the resistance of the system increases rapidly from the 120th minute. The resistance of the system increases to the peak at about 140 minutes, and changes little thereafter. Therefore, it can be judged that the initial setting time of the system gel is 120 minutes, and the final setting time is 140 minutes.

Embodiment 2

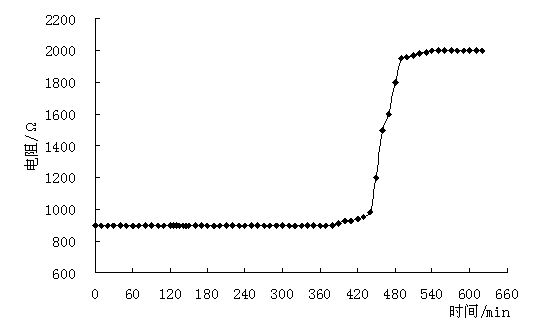

[0018] Embodiment two Add the flocculation-type inorganic gel system composed of 6% polyaluminum chloride and 3% urea into the reaction kettle 4, and immerse the electrode in the middle of the solution, and fill the reaction kettle 4 with nitrogen to 20MPa through the booster device 6 , and then the temperature was kept constant to 100°C, and the pressure in the reactor was kept constant during the heating process. Start the multimeter 1 to measure the change of system resistance. See the measurement results image 3 . according to image 3 From the measurement results, it can be seen that the resistance of the system does not change much in the first 430 minutes, and the resistance of the system increases rapidly from the 440th minute. The resistance of the system increases to a peak value at about 500 minutes, and changes little thereafter. Therefore, it can be judged that the initial setting time of the system gel is 440 minutes, and the final setting time is 490 min...

Embodiment 3

[0019] Example 3 Add an organic gel system composed of 0.3% polyacrylamide copolymer (molecular weight: 30 million) and 0.3% organic chromium crosslinking agent into the reaction kettle 4, and immerse the electrode into the middle of the solution. The pressure device 6 fills the reactor 4 with air to 10 MPa, and then keeps the temperature at 75° C., and keeps the pressure in the reactor constant during the heating process. Start the multimeter 1 to measure the change of system resistance. See the measurement results Figure 4 . according to Figure 4 From the measurement results, it can be seen that the system resistance does not change much in the first 1090 minutes, and the system resistance increases rapidly from the 1090 minutes. The resistance of the system increases to the peak at about 1190 minutes, and changes little thereafter. Therefore, it can be judged that the gel initial setting time of the system is 1090 minutes, and the final setting time is 1190 minutes. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com