Hall self-adaptive sensor

A sensor and self-adaptive technology, applied to devices using electric/magnetic methods, etc., can solve the problems of inability to detect at zero speed, low sensitivity sensing distance, and low adaptability to the magnetic field of magnetic steel, achieving high reliability and convenient application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

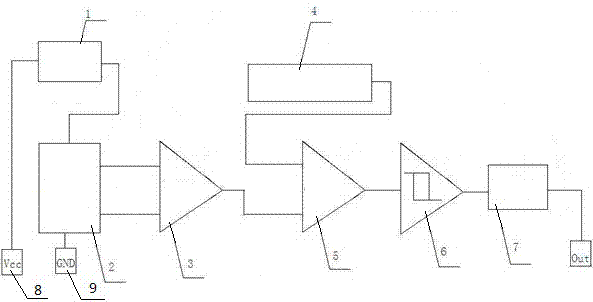

[0018] Embodiment 1: as figure 1 As shown, the Hall adaptive sensor of this embodiment consists of a step-down regulator structure 1, a Hall sensing head 2, an amplifier 3, an adaptive logic structure 4, a comparator 5, a hysteresis comparator 6, an output circuit 7, a power supply 8. The grounding point is composed of 9. The buck regulator structure 1 , the Hall sensor head 2 , the amplifier 3 , the comparator 5 , the hysteresis comparator 6 and the output circuit 7 are sequentially connected, and the self-adaptive logic structure 4 is connected to the comparator 5 .

[0019] The buck-stabilizing structure 1 is the buck-stabilizing structure of the present invention, which can stably provide the internal circuit with a voltage of 3-5V when the external power supply 8Vcc is between 5V and 40V.

[0020] The Hall sensor head 2 is a Hall plate sensor head of the present invention, which is used as an input part to enable the sensor to sense an external magnetic field, and conver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com