Low-temperature lead-acid battery cathode active substance and preparation method thereof

A negative electrode active material, lead-acid battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low temperature capacity and cycle life of batteries, affecting battery discharge performance, charging performance, etc., and achieve low temperature charging acceptance. Ability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions and positive effects of the present invention are further described below through examples.

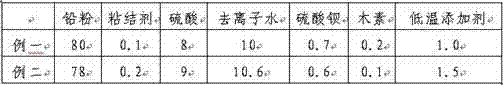

[0014] The components and mass percentages of low-temperature additives in Example 1 and Example 2 are shown in Table 1:

[0015] Table 1

[0016]

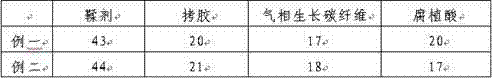

[0017] The components and mass percentages of the negative electrode active material in Example 1 and Example 2 are shown in Table 2:

[0018] Table 2

[0019]

[0020] In the table, the density of sulfuric acid is 1.32g / ml (25°C), and the binder is a common binder in this industry.

[0021] The preparation method of example one, example two is:

[0022] Prepare materials according to the proportions in Table 1 and Table 2: fully stir the prepared lead powder, binder, barium sulfate, lignin, and low-temperature additives in a dry state for 12 minutes (Example 1) and 13 minutes (Example 2) , add deionized water at a uniform speed within 7 minutes, stir while adding, continue stirring for 8 minutes (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com