Positive electrode material, positive plate, lithium ion battery cell, lithium ion battery pack and application thereof

A lithium-ion battery and cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of battery life and safety risks, battery life and safety hazards, low voltage platform, etc., to improve low-temperature performance and low temperature capacity retention rate, which is beneficial to debugging and work, and the effect of smooth charging and discharging voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

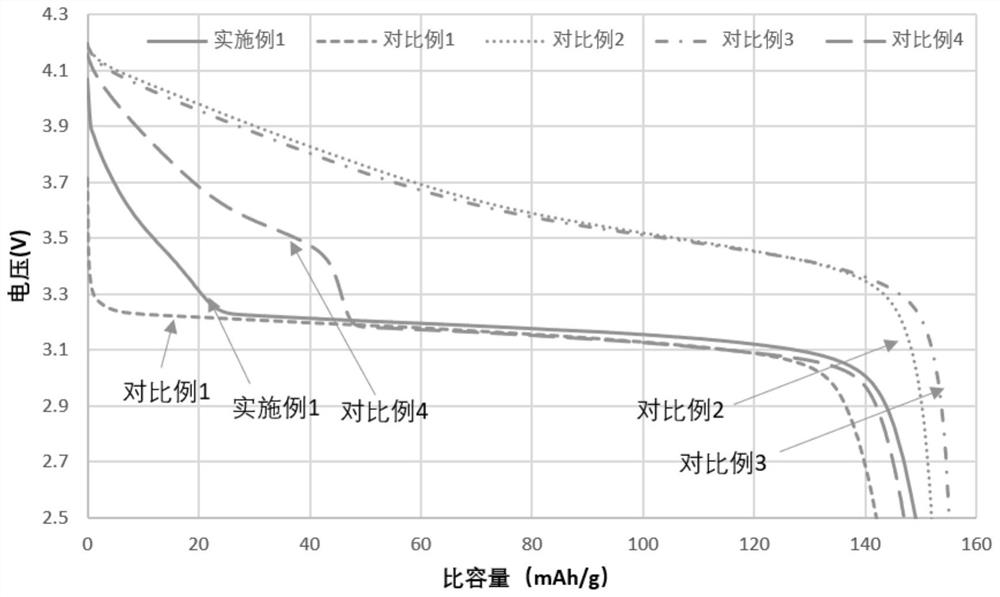

Embodiment 1

[0039] (1) Preparation of positive electrode plate

[0040] The cathode active material lithium iron phosphate LiFePO 4 , LiNiCoMnLiNi 0.5 Co 0.2 Mn 0.3 O 2 (Narrow distribution of small particle size single crystal material, D50 is 2um, Span=0.8, tested, 3.2g / cm 3 The powder conductivity under compaction is 0.0032mS / cm, the reversible gram capacity is 171mAh / g) and the conductive agent super-P, CNT, and the binder PVDF are mixed uniformly in a mass ratio of 70:26.8:1.5:0.5:1.2. N-methylpyrrolidone (NMP) is uniformly stirred and mixed by a vacuum mixer to obtain a positive electrode active material slurry. The above slurry is uniformly coated on both sides of the current collector of aluminum foil (thickness 13 μm), dried, cold pressed and slit to obtain a positive electrode piece.

[0041] (2) Preparation of negative pole piece

[0042] The negative electrode active material graphite, conductive carbon black (super-P), sodium carboxymethyl cellulose (CMC), and styrene-...

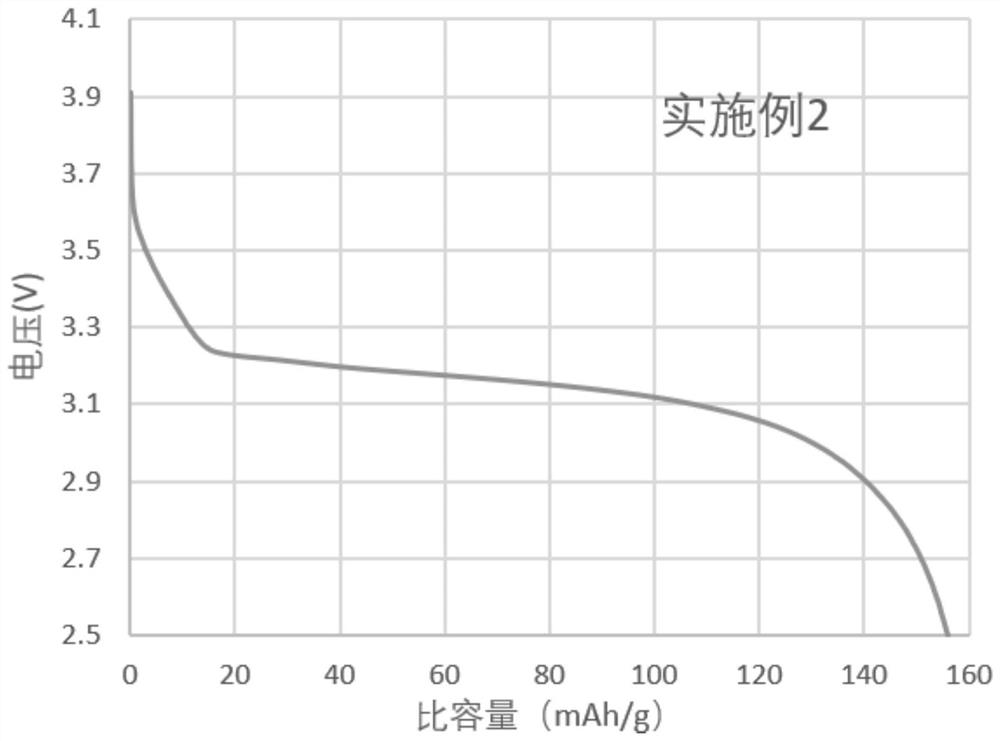

Embodiment 2

[0048] The cathode active material lithium iron phosphate LiFePO 4 , High impedance ternary material LiNi with Al doping content of 3% 0.6 Co 0.2 Mn 0.2 O 2 (D50 is 5um, Span=0.6, tested, 3.2g / cm 3 The powder conductivity under compaction is 0.0022mS / cm, the reversible gram capacity is 178mAh / g) and the conductive agent super-P, CNT, and the binder PVDF are mixed uniformly in a mass ratio of 60:38:0.5:0.5:1.0, and added N-methylpyrrolidone (NMP) is uniformly stirred and mixed by a vacuum mixer to obtain a positive electrode active material slurry. The above slurry is uniformly coated on both sides of the current collector of aluminum foil (thickness 13 μm), dried, cold pressed and slit to obtain a positive electrode piece. The remaining steps were carried out as in Example 1.

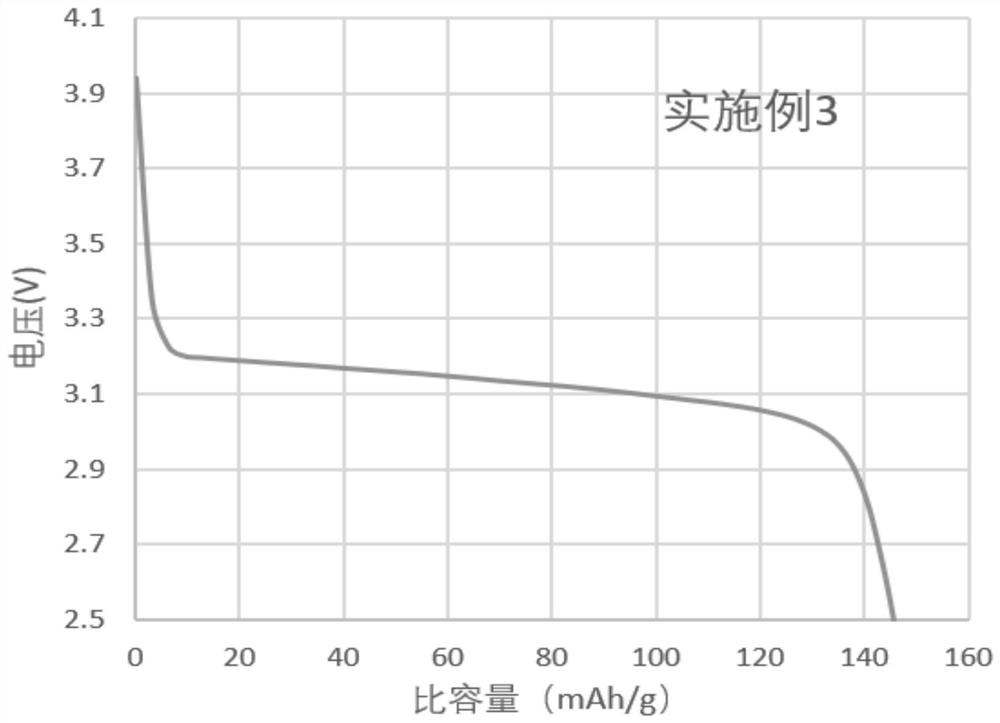

Embodiment 3

[0050] The cathode active material lithium iron phosphate LiFePO 4 , high impedance cobalt-free material LiNi 0.75 Mn 0.25 O 2 (D50 is 4.5um, Span=0.7, tested, 3.2g / cm 3 The powder conductivity under compaction is 0.0034mS / cm, the reversible gram capacity is 185mAh / g) and the conductive agent super-P, CNT, and the binder PVDF are mixed uniformly in a mass ratio of 90:8:0.5:0.5:1.0, and added N-methylpyrrolidone (NMP) is uniformly stirred and mixed by a vacuum mixer to obtain a positive electrode active material slurry. The above slurry is uniformly coated on both sides of the current collector of aluminum foil (thickness 13 μm), dried, cold pressed and slit to obtain a positive electrode piece. The remaining steps were carried out as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com