Lifter displacement control device

A technology of displacement control and hoist, which is applied in the direction of elevator, transportation and packaging, etc. It can solve the problems of equipment tilt, hoist cannot run synchronously, and the speed of rising and falling is different, so as to achieve convenient operation, easy transplantation, and wide range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

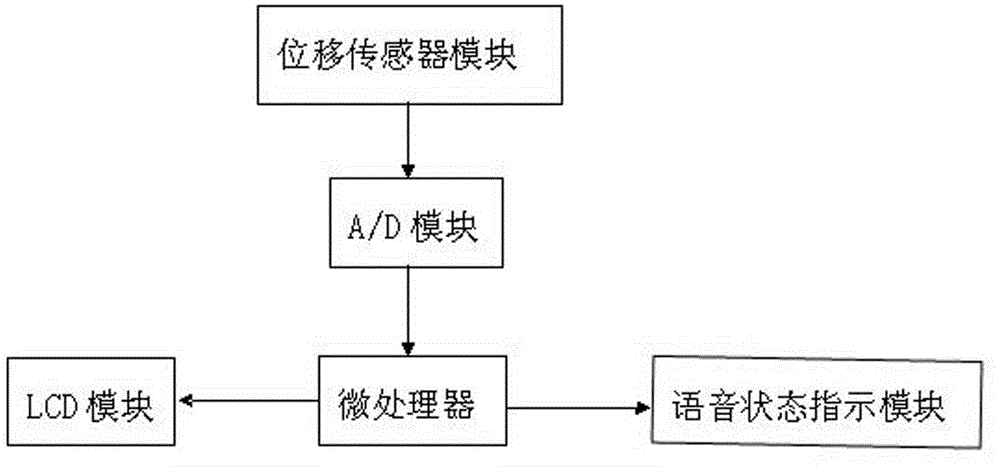

[0014] see figure 1 Shown: a hoist displacement control device, which includes a displacement sensor module, an A / D module, an LCD module, a microprocessor, and a voice status indication module, the displacement sensor module and the A / D module are connected in sequence, and the The above-mentioned A / D module, LCD module and voice broadcast module are respectively connected with the microprocessor sequentially for distributed control.

[0015] A hoist displacement control device, the microprocessor type is AVR.

[0016] A hoist displacement control device, the displacement sensor module is GH-719.

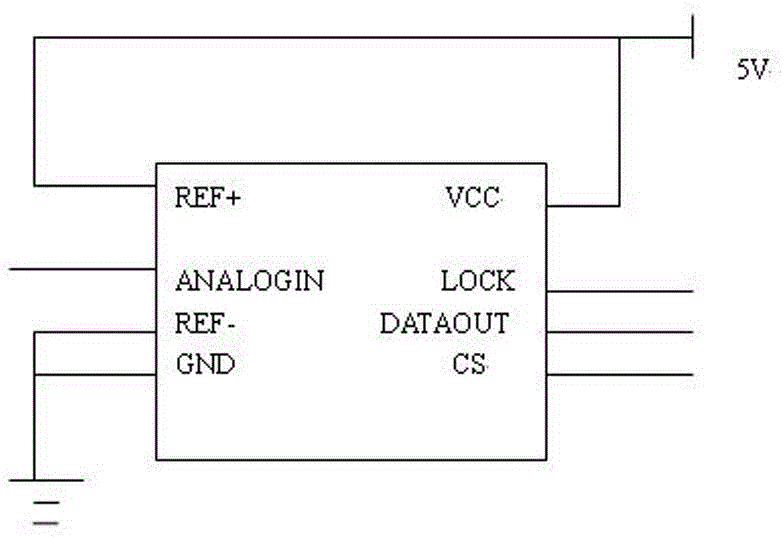

[0017] see figure 2 As shown, a hoist displacement control device, the core chip of the A / D module is ADC0809.

[0018] A hoist displacement control device, the type of the voice state indication module is LD3320.

[0019] In the invention, the A / D module converts the displacement signal of the displacement sensor module into a digital signal, and then conducts further quantit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com