Local-stage aqueous-phase inner circulation device with box-type extraction tank

A box-type extraction tank and internal circulation technology, applied in the direction of liquid solution solvent extraction, process efficiency improvement, etc., can solve problems such as troublesome, prolonged reaction equilibrium time, poor washing and stripping effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the embodiments in the accompanying drawings, but this does not constitute any limitation to the present invention.

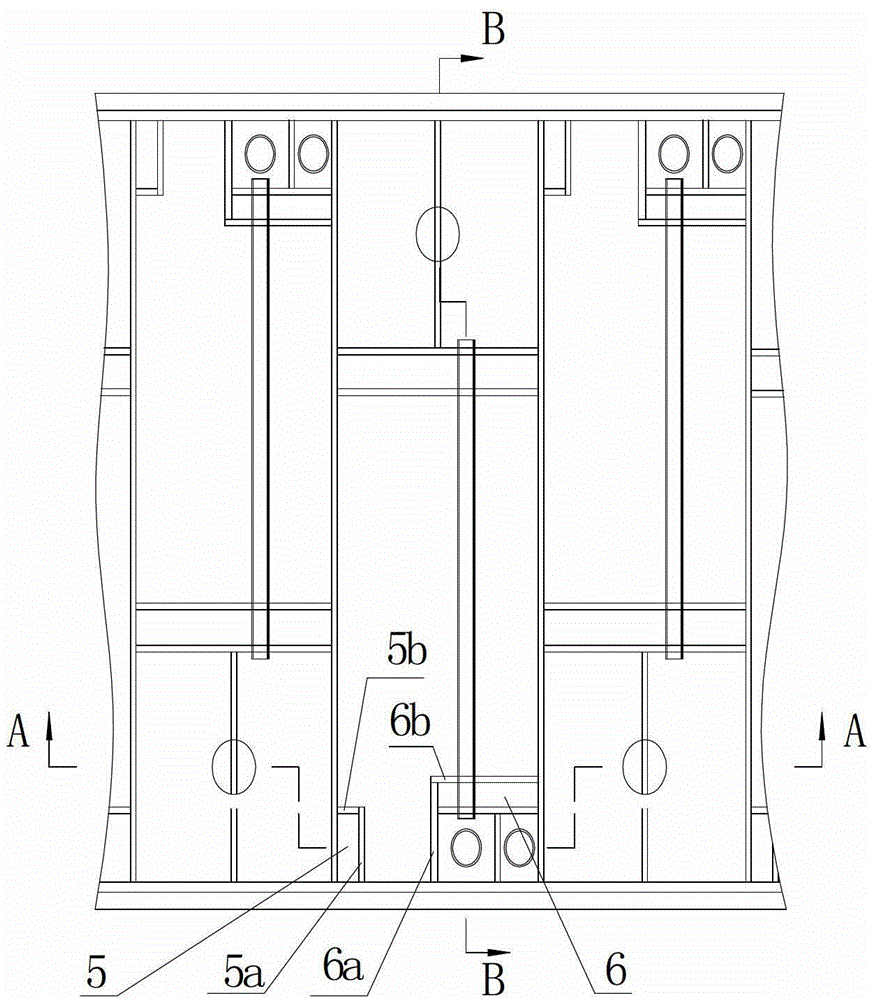

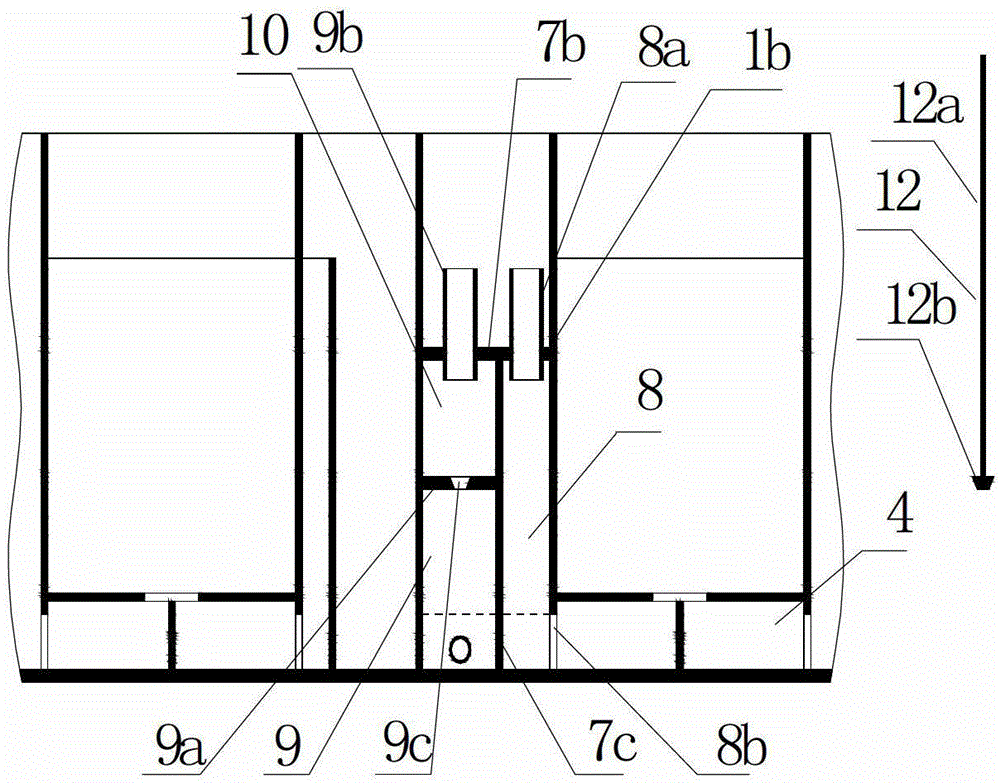

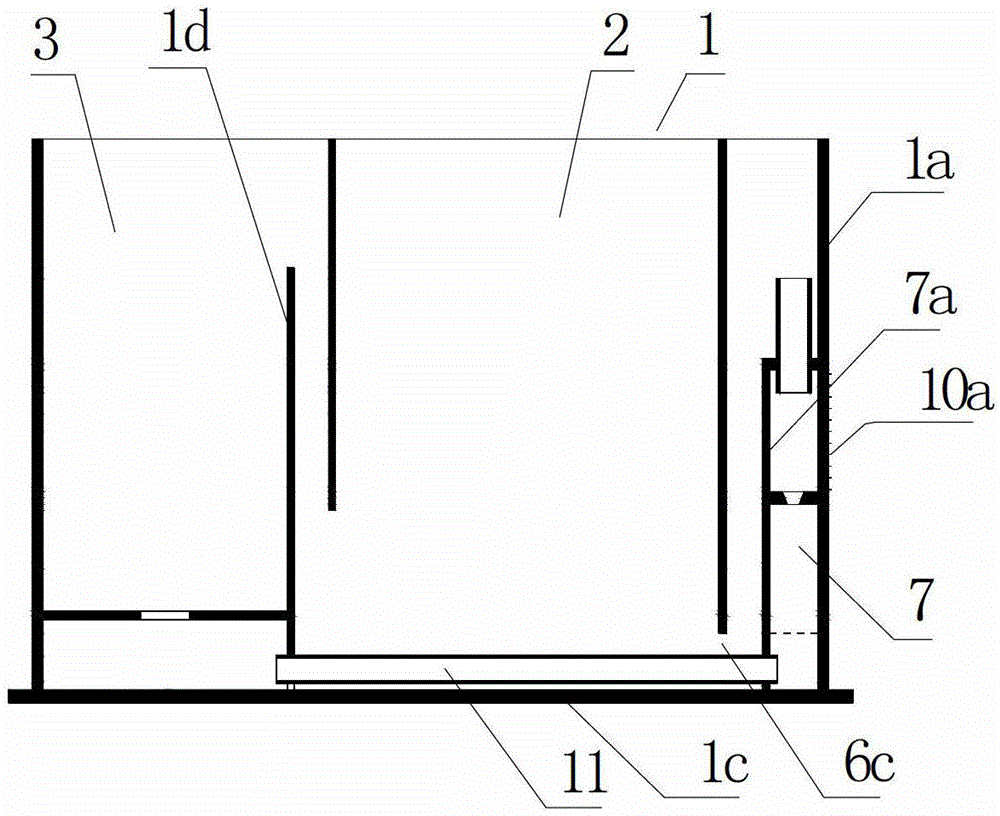

[0018] refer to figure 1 , figure 2 , image 3 As shown, the internal circulation device of the box-type extraction tank of the present invention includes an extraction tank body 1, wherein the extraction tank body 1 is provided with a clarification chamber 2, a mixing chamber 3 and a latent chamber 4, and the clarification chamber 2. An organic phase cofferdam 5 and an aqueous phase cofferdam 6 are provided for the organic phase and the aqueous phase to flow into the submerged chamber 4 and the mixing chamber 3. An aqueous phase chamber 7 is arranged in the aqueous phase cofferdam 6. In the aqueous phase chamber 7 A water phase partition 7c is provided inside to divide the water phase chamber into two independent small water phase chambers, the interstage water phase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com