Spinning box

A spinning box and spinneret technology, which is applied in the field of chemical fiber filament machinery manufacturing, can solve the problems of low yarn output, low yarn efficiency, and restricted distribution of spinneret plate holes, so as to avoid filaments and breakage. head, improve production efficiency, eliminate the effect of flow dead center

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

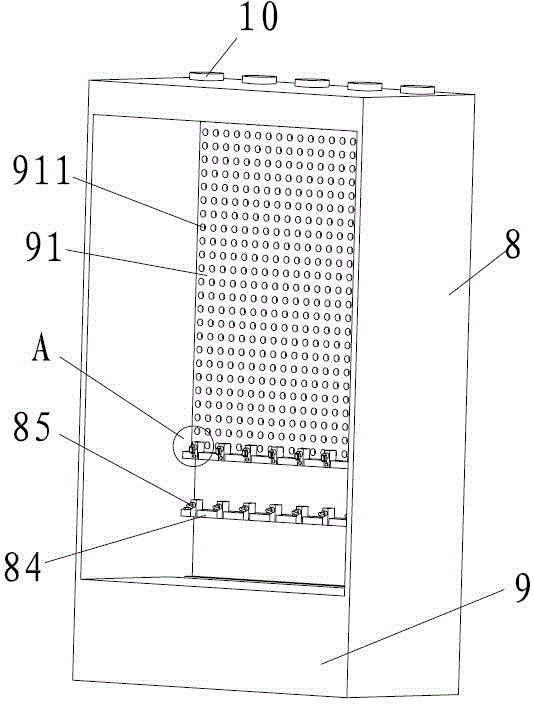

[0035] Embodiment 1: as Figure 1-8 As shown, a spinning box includes a frame 8, a yarn spray tank 10 positioned on the top of the frame 8, a blowing mechanism for blowing the yarn, a yarn guide assembly arranged between the two sides of the frame 8, and a Between the two sides of the frame 8 and the yarn drawing assembly below the yarn guiding assembly and the yarn collection box 9 below the frame 8 .

[0036] The blowing mechanism includes a fan, and a wind plate 91 communicating with the fan and having a plurality of air holes 911; the fan is not shown in the figure.

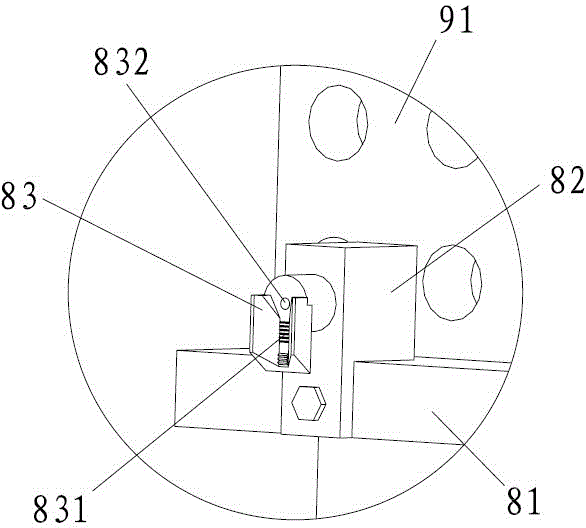

[0037] The yarn guide assembly includes a crosspiece 81 arranged between the two sides of the frame 8, a base 82 is arranged on the crosspiece 81, and a poly yarn that gathers a plurality of yarns and injects oil is fixed on the base 82. The thread-gathering piece 83 has a plurality of protrusions 831 distributed longitudinally in the middle of the wire-gathering piece 83, and an oil hole 832 for spraying oi...

Embodiment 2

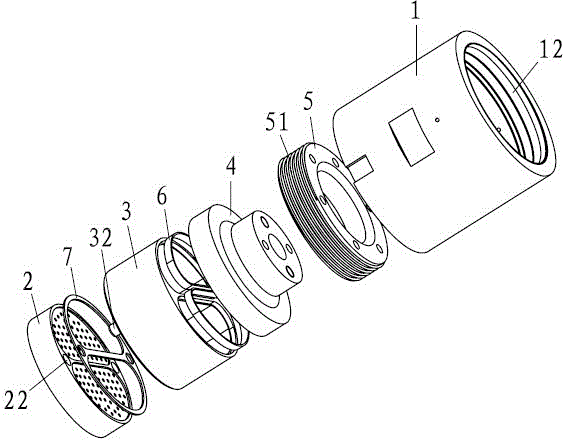

[0042] Embodiment 2: The difference with Embodiment 1 is that, as Figure 9-10 As shown, the height of the sealing ring is relatively large; there is no step on the upper inner wall of the flow channel 31 , and one end of the sealing ring is in contact with the filter plate 311 .

Embodiment 3

[0043] Embodiment 3: The difference with Embodiment 1 is that, as Figure 11 As shown, the diversion area 43 is provided with a groove 431 , the side wall of the groove 431 is on the same surface as the inner side wall of the diversion area 43 ; one end of the sealing ring is inserted into the groove 431 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com