Ballast cleaning machine

A technology of screen cleaning machine and body, applied in the field of machinery, can solve the problems of low stability and safety, small distance and range of throwing dirt, and achieve the effect of improving discharge efficiency and increasing the distance and range of throwing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

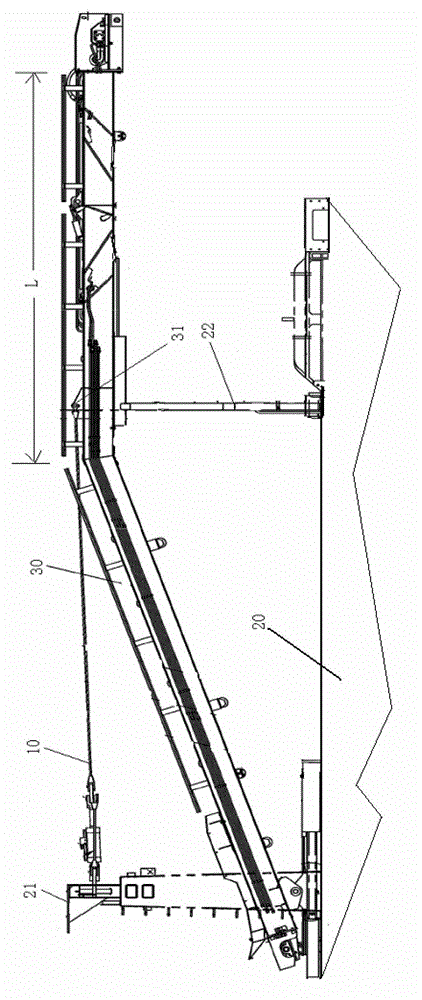

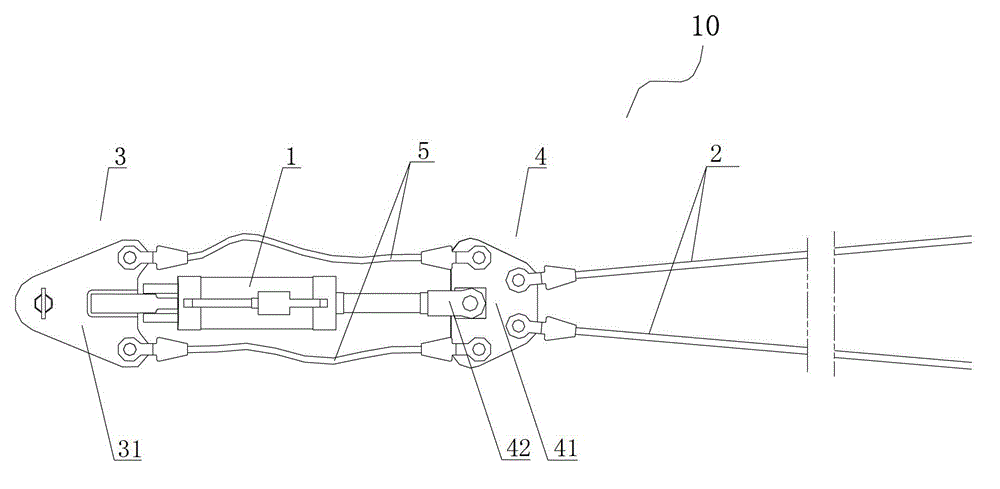

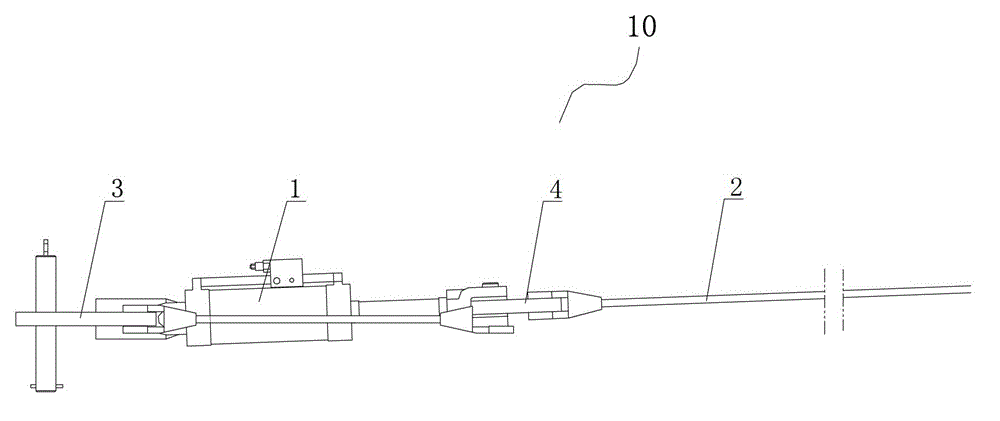

[0029] The embodiment of the present invention provides a cleaning machine, specifically a ballast cleaning machine with a tension lifting mechanism, such as figure 1 As shown, the sieve cleaning machine includes a sieve cleaning machine body 20, on which a rotary conveying mechanism 30 and a tensioning lifting mechanism 10 for tightening and lifting the rotary conveying mechanism 30 are arranged, and the tensioning lifting One end of the mechanism 10 is connected with a pillar 21 having a certain height on the body 20 of the cleaning machine, and the other end is connected with the rotary conveying mechanism 30 . The sieve cleaning machine provided in this embodiment can make the sieve-cleaning mechanism 30 have stronger mechanical strength by arranging the tensioning lifting mechanism 10 for tightening and lifting the sieve-cleaning mechanism 30 on the body 20 of the sieve cleaning machine, Improve the stability of the rotary conveying mechanism 30, like this, the length of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com