Self-reset frictional sliding isolation bearing

A seismic isolation bearing and self-resetting technology, which is applied in the direction of earthquake resistance, building components, construction, etc., can solve the problems of not considering the dynamic characteristics of the structure, the automatic reset of the structure after a difficult earthquake, and the difficulty of realizing the structural system, etc., to achieve a good instantaneous automatic Effect of reset function, improvement of operating temperature range and durability, improvement of living comfort and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in combination with technical solutions and with reference to the accompanying drawings.

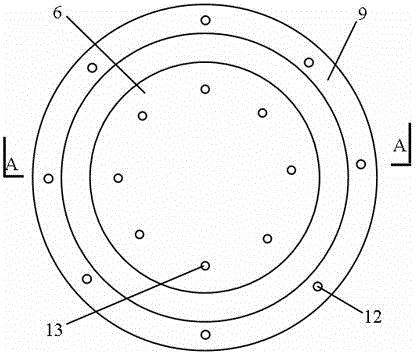

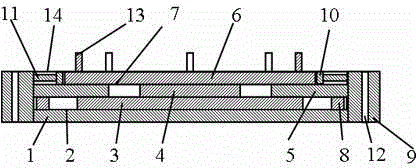

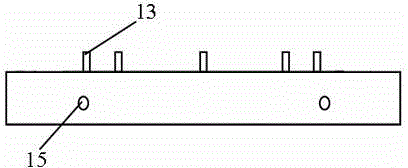

[0019] Such as Figure 1~Figure 3 As shown, the self-resetting friction sliding seismic isolation bearing of the present invention includes a base plate 1, a base plate friction plate 2, a movable double-sided friction plate 3, a connecting plate 4, a fixed double-sided friction plate 5, a bearing plate 6, and a bearing plate Friction plate 7, forced reset device 8, outer ring plate 9, foundation micro-vibration and wind response control device 10, automatic reset device 11, cover plate 14 and forced reset operation hole 15, the bottom plate 1 is circular and has a single Friction plate 2 of one-sided bottom plate, fixed double-sided friction plate 5 is circular, bottom plate 1, single-sided bottom plate friction plate 2, fixed double-sided friction plate 5 are all welded to outer ring plate 9; movable double-sided friction p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com