Explosion-proof room for air pressure test

A technology of air pressure test and pressure relief, which is applied in the field of explosion-proof devices for testing and explosion-proof rooms for air pressure tests, which can solve the problems of poor explosion-proof effect of explosion-proof rooms and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

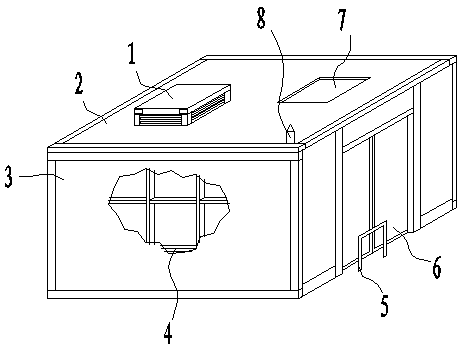

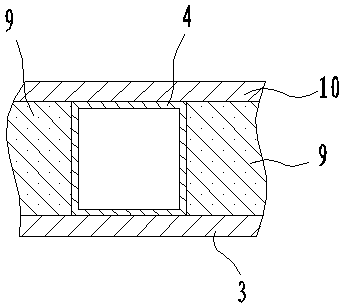

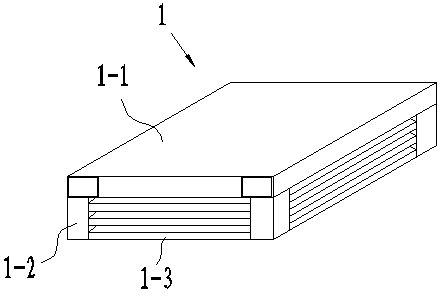

[0024] Such as figure 1 , figure 2 As shown, the present invention includes body of wall, top cover 2, explosion-proof sliding door 6. The wall includes a structural steel frame 4, which is welded longitudinally and horizontally by rectangular steel pipes, and has a cross-shaped mesh structure; the inner and outer walls of the structural steel frame 4 are respectively covered with inner panels 10 and The outer panel 3 ; the space enclosed by the other side walls of the structural steel frame 4 , the inner panel 10 and the outer panel 3 is filled with damping sand 9 . The components of damping sand 9 are 95-105 parts of cement, 60-70 parts of medium sand, 18-22 parts of perlite and 28-32 parts of water; the above-mentioned components are mixed uniformly and solidified and dried, and are composed of the above-mentioned components The dam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com