Structure construction and construction method of steel truss bow-tie type integrated node

A technology of integral joint and structural structure, applied in the field of steel truss structure, can solve the problems of unexplained assembly and construction method, lack of operability, no consideration of joint structure details and component composition, etc., which is conducive to structural optimization and reduces site Welding work, the effect of improving material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention are described in detail below, and the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are provided, but the protection scope of the present invention is not limited to the following embodiments.

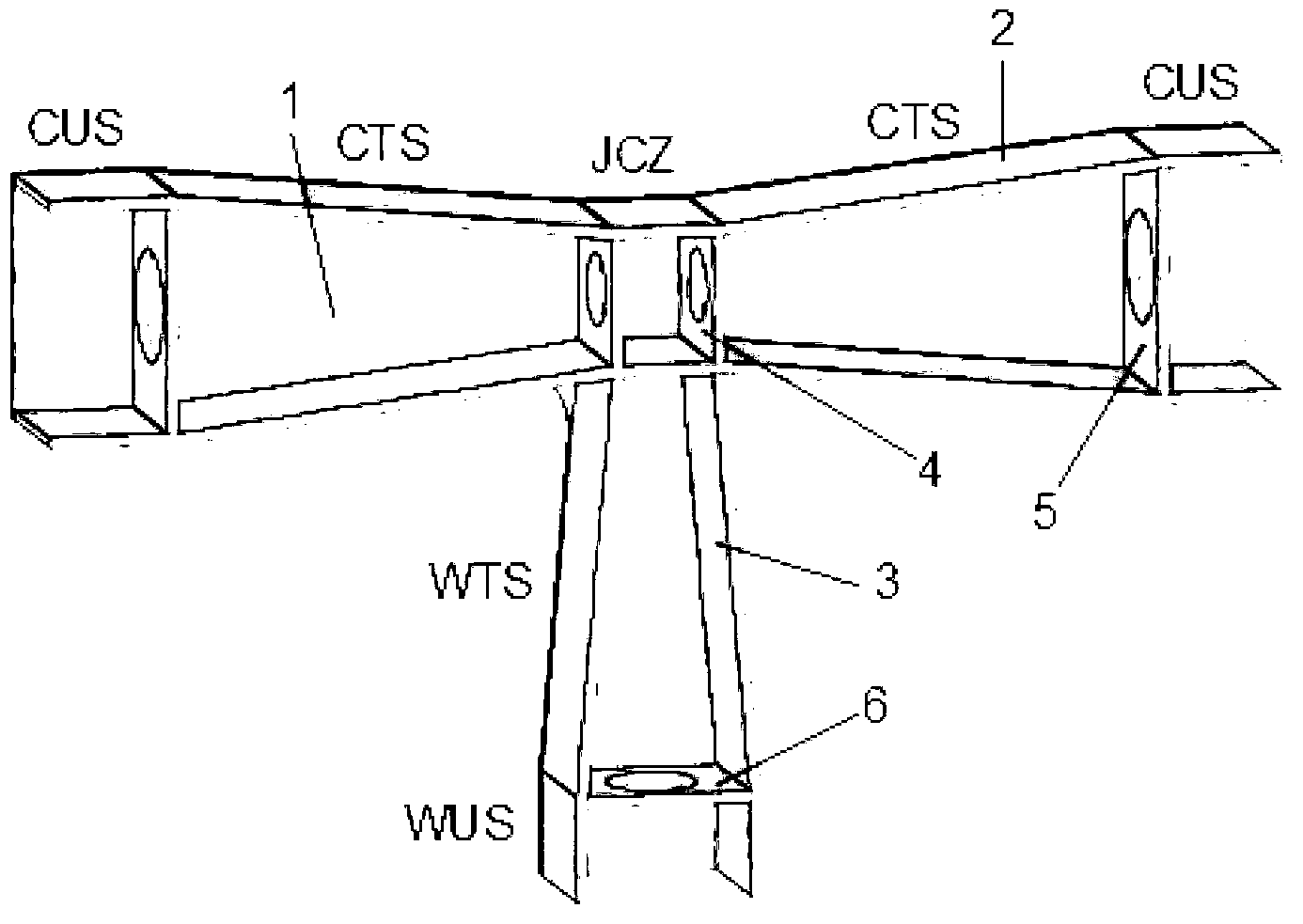

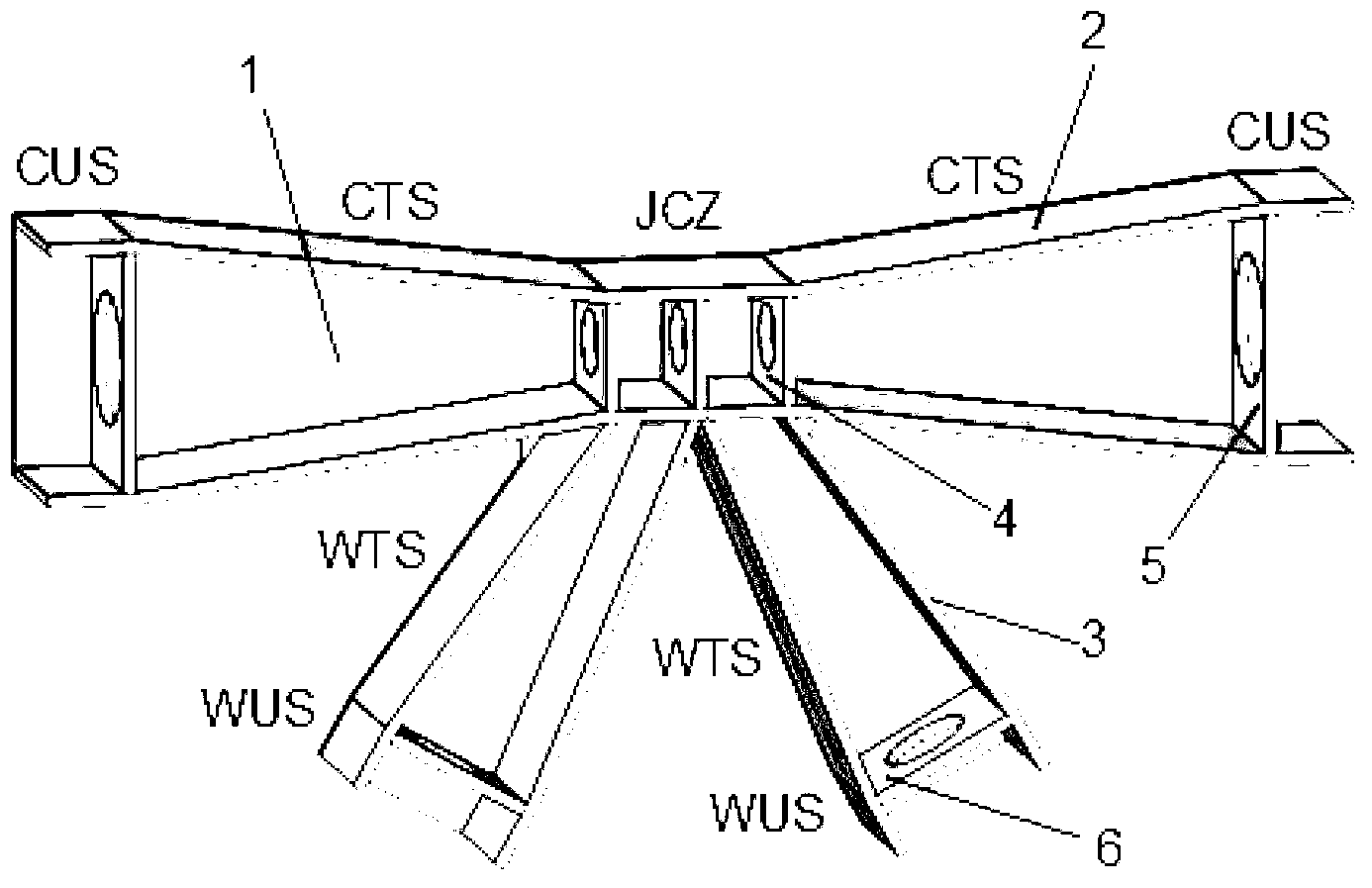

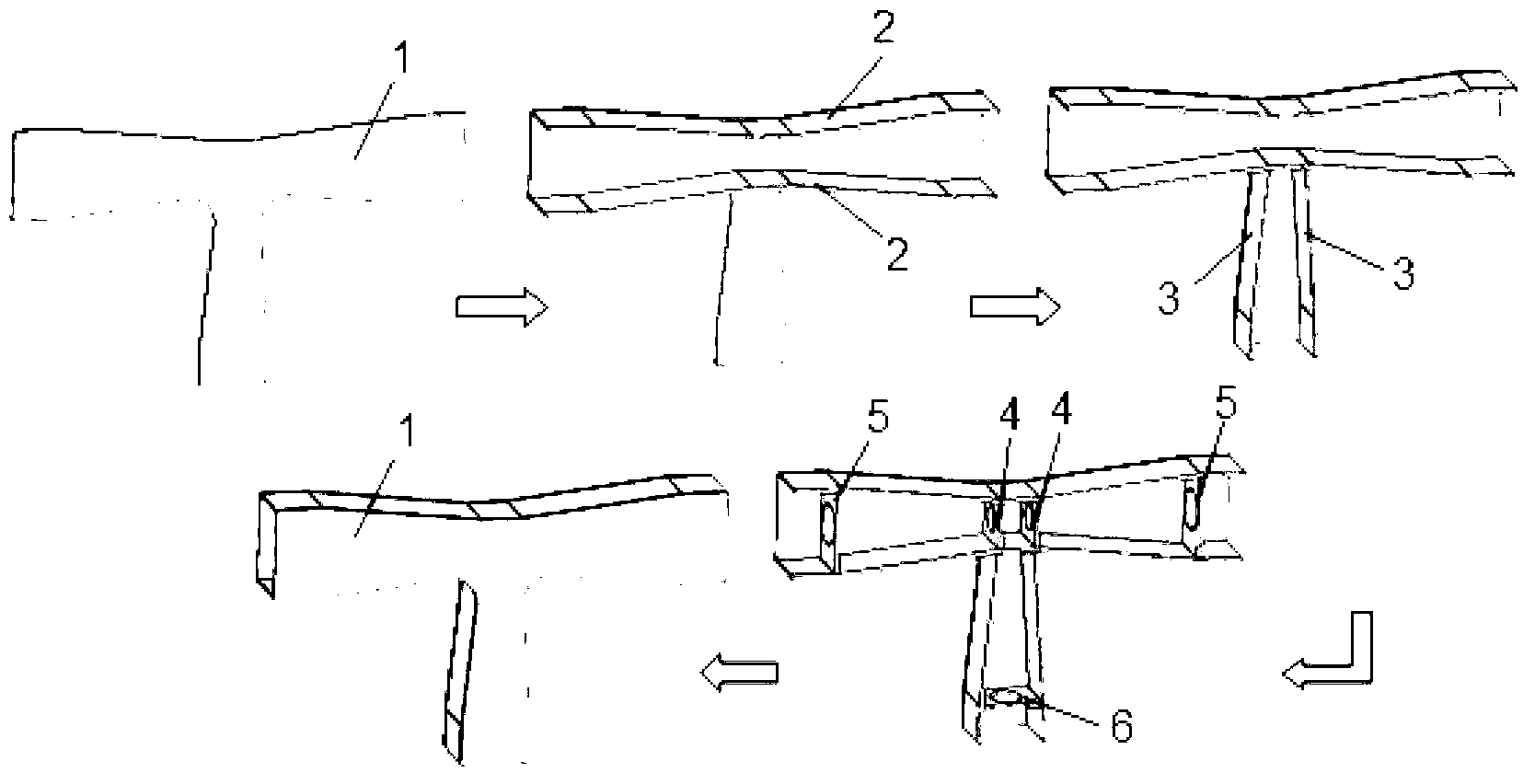

[0040] Such as figure 1 As shown, a T-shaped steel truss bow-tie integral joint is welded by three kinds of steel plates, which are respectively web 1, flange plates 2, 3 and diaphragms 4, 5, 6; the web 1 is composed of The chord part and the web part form a T shape, and the junction of the T-shaped chord part and the web part is the entire node core zone JCZ, and the section height of the node core zone JCZ is the smallest, and then from the node core zone JCZ to the web The section heights of the left and right ends of the T-shaped chord part of the plate 1 and the direction of the web 1 web part gradually increase; where: from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com