Solid wood feeling melamine board

A melamine board, solid wood technology, applied in the direction of sheet/board, building components, etc., can solve the problems of texture inconsistency, texture structure inconsistency, texture layer texture inconsistency, etc., achieve texture coordination, protect the environment, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

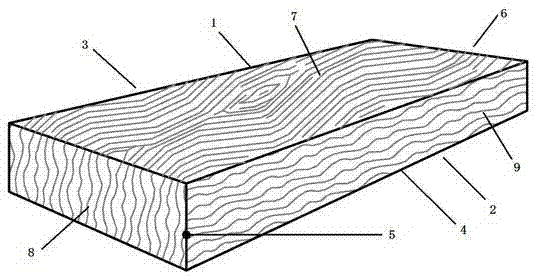

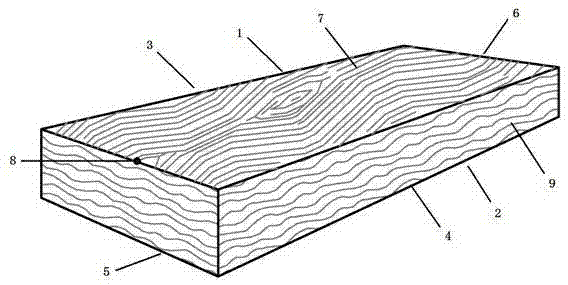

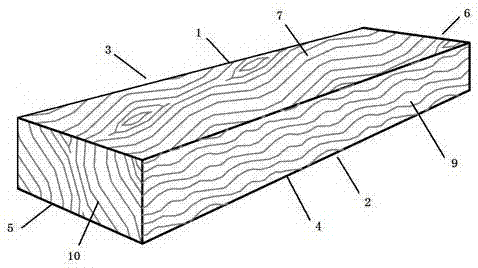

[0020] Such as image 3 As shown, a solid wood feeling melamine board is mainly composed of a top board 1, a bottom board 2, a left side board 3, a right side board 4, a front side board 5 and a rear side board 6 to form a rectangular board, and the top board 1 and the base plate 2 all have a solid wood surface texture layer 7, the left edge band 3 and the right edge band 4 have a solid wood grain texture layer 9, and the front end edge band 5 and the rear end edge band 6 have a solid wood end grain texture layer 10. The textures of the solid wood surface texture layer 7, the solid wood along-grain texture layer 9 and the solid wood end-grain texture layer 10 correspond to each other.

[0021] Such as Figure 4 As shown, in order to make the melamine board have a more real solid wood splicing effect, the solid wood surface texture layer 7 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com