Construction method for erecting overhead line system power supply line based on unmanned aerial vehicle technology

A construction method and power supply line technology, which is applied in the construction field of erecting catenary power supply lines based on UAV technology, can solve the problems of unsatisfactory railway power supply lines, high safety factor, high voltage level of railway power supply lines, etc., and achieve guaranteed strength and Reliability and safety of power supply, avoiding tree felling, and enhancing the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

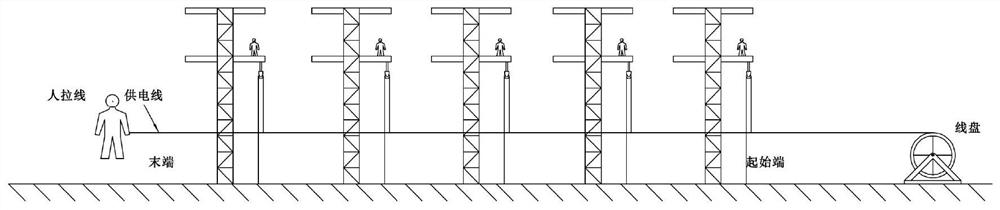

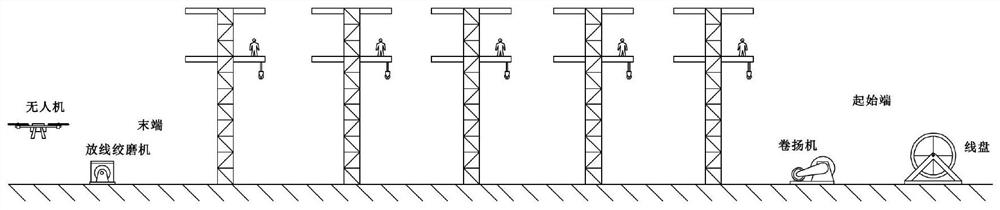

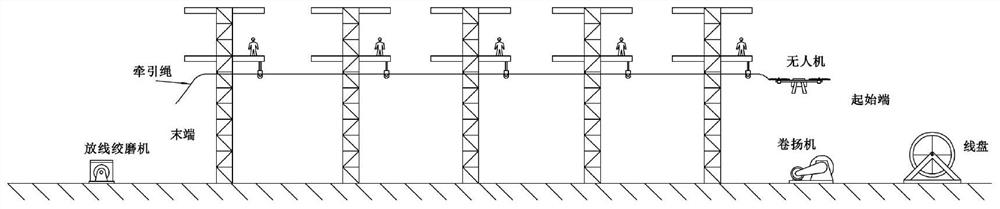

[0025] This embodiment provides a construction method for erecting catenary power supply lines based on unmanned aerial vehicle technology, referring to Figure 6 , which includes the following steps, S1 refers to figure 2 , firstly carry out the preparatory work of the whole construction method, that is, the layout of the equipment, place the unmanned aerial vehicle and the payout winch at the end of the anchor section that needs to be released, and set the winch at the beginning of the anchor section that needs to be released, corresponding to the In the accompanying drawings, the left side is the end of the anchor section that needs to be released, and the right side is the beginning of the anchor section that needs to be released. A steel wire rope is wound on the pay-off winch mill. Fix the reel where the power supply line is located on the pay-off bracket, pull out the end of the wire to prepare for the release, and place it at the beginning of the anchor section that ...

Embodiment 2

[0043] The difference between embodiment 2 and embodiment 1 is that in step S5, when lifting the anchor, this embodiment has two power supply lines, and the anchor connection mode of the two power supply lines is Z-10 four-legged right-angle hanging board, 18 pestle ring rods, Suspension insulator (XWP2-70), WS-10 double bowl head hanging plate, L-1240 type connecting plate and 2* pre-twisted wire tension clamps are connected, and the above-mentioned components are connected. The connection process and method are as follows: The technique is well known to those skilled in the art.

Embodiment 3

[0045] The difference between Example 3 and Example 1 is that in step S5, the suspension connection mode of a single power supply line is a long suspension ring (with ball suspension), 4 pieces of pestle head suspension insulators, suspension clamps (CGU-5A) and pre-twisted The connection of the type short protective strip, the connection of the above-mentioned components, the connection process and method are well known to those skilled in the art. Tighten the hook bolt at the same time, retract the sleeve and the pay-off pulley.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com