Light guide plate repairing method

A repair method and light guide plate technology, applied in the direction of light guides, optics, optical components, etc., can solve the problems of wasted light guide plate product yield, decline, etc., to achieve the effects of improving yield, reducing scrap rate, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

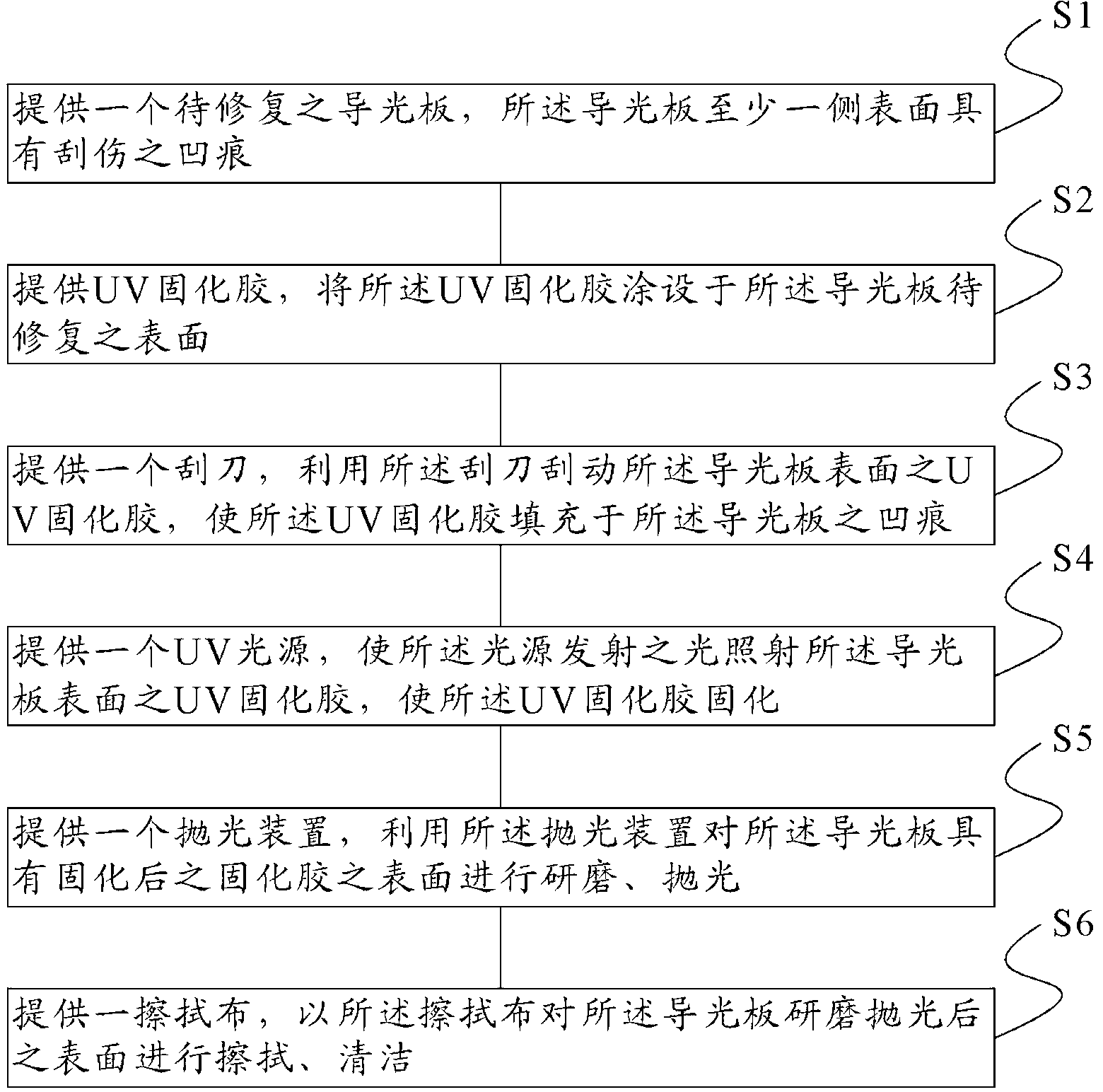

[0019] see figure 1 , which is a flowchart of a method for repairing a light guide plate according to an embodiment of the present invention, the method for repairing a light guide plate includes the following steps:

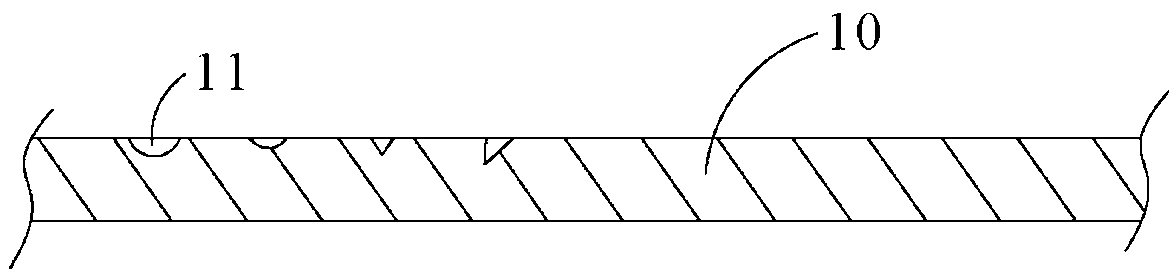

[0020] Step S1, please also refer to figure 2 , providing a light guide plate 10 to be repaired, at least one side surface of the light guide plate 10 has scratched dents 11 . In this embodiment, the light guide plate 10 is placed horizontally, and the side surface with the indentation 11 faces upward. The material of the light guide plate 10 is polymethylmethacrylate (polymethylmethacrylate: PMMA).

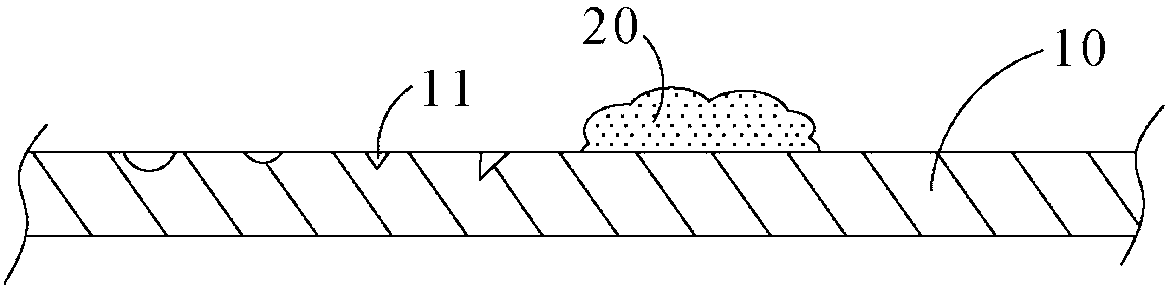

[0021] Step S2, please also refer to image 3 , providing an ultraviolet (ultraviolet: UV) curing glue 20, and coating the UV curing glue 20 on the surface of the light guide plate 10 to be repaired. The UV-curable glue 20 is a water-soluble low-vis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com